SWEDEN Noise control: Test cell improves environment for gas turbine overhauls

A noise suppression test cell is to be built by Hedemora Industriakustik for GE Energy in Bergen for the testing of North Sea platform gas turbines. The facility is scheduled for completion in June. Once in operation, the sound suppression cell will be used for the operational testing each year of on average thirty LM 2500 and LM 2500+ gas turbine engines used for power generation in the North Sea.

The test cell will have the ability to reduce noise emissions from PWL 160 dB to 55 dB at 100 meters via a building measuring 45 meters long, internal 6 meters wide and 6 meters high. Built from concrete, the sound proofing components of the test cell will consist of an inlet stack with an air intake silencer and a screen of vanes for turning the direction of the air flow. Intake air will pass through a bias screen into the acoustically lined concrete test cell for which Hedemora will also supply sound-proofed double doors and a personnel access door. This will be followed by an exhaust tube that carries gases into an exhaust stack fitted with an exhaust silencer.

No mufflers

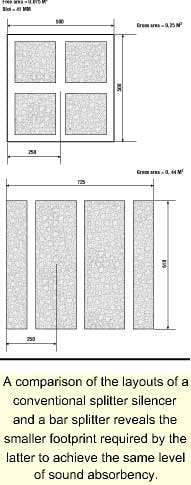

The unique characteristics of the Hedemora system arise from the use of bar silencers. These have been designed to achieve higher performance than conventional muffler silen-cers that employ continuous panels of sound-absorbing material and which expose just two surfaces to the air or exhaust gas flow. The bar design employs a number of square columns of sound-absorbing material that are suspended within the air intake and exhaust stack. Since the air passes over all four sides of each bar, Hedemora designers can expose a higher surface area of sound-absorbing material in an array that occupies less section area than conventional mufflers.

The bar silencers provide a secondary benefit in relation to air intake performance. The flat panels of a conventional system need to be aligned in accordance with the prevailing wind to ensure optimum airflow entry. Crosswinds can affect the intake silencer's air flow performance. This is not a problem with bar silencers as their symmetrical configuration offers almost the same performance, regardless of its direction.

Because of its reduced size, the bar silencer design also has the advantage of being very cost effective when compared with conventional systems. It is also easier to install or dismantle for maintenance in locations where space may be limited. Since the bar components can be installed individually they are easier to handle than the large flat baffles of a conventional system.

Minimal data requirement

Hedemora Industriakustik has been designing sound suppression systems for over 40 years and this experience makes it possible for the company's designers to plan a system very quickly. The only information needed is the sound power level and the thrust of the engine to be silenced and this can be efficiently converted into the plans for an effective system.

The company's sound suppression enclosures for offshore applications are manufactured mainly from stainless steel or aluminum. This is used for the main structure and to contain mineral wool that serves as the sound-absorbent material. The wool will be deployed in the thicknesses necessary for absorbing the low frequency sound from the engine while the length of the silencer bars themselves and the size of the gaps be-tween them will be determined by the high frequency sound absorption requirements. The company will usually call-upon one of three different types of mineral wool in densities in the range of 80-110 kg/cu meter. This will be distributed in varying thicknesses around the installation and may reach 750 mm on the exhaust tube where it will also be required to withstand temperatures of 200-300°C.

Hedemora Industriakustik is based in Hede-mora, Sweden where, in addition to test cells, it also designs and manufactures sound suppressant steam and gas turbine enclosures for offshore and marine use, acoustic panels and hush houses for military aircraft testing - having built its first silencer for the Swedish Air Force in 1953. The company expects to deliver some 20 systems this year.

For more information, contact Lars Tallkvist, Hedemora Industriakustik: tel +46 225 15560, fax +46 225 15435, E-mail: [email protected]