Tubular design for 28,000 ft US Gulf of Mexico record well

String load, annular mechanics, hydraulics are critical

Kevin McMillin

Engineering Editor

Unforeseen pressure horizons required the use of two rigs to complete the EEX Llano Garden Banks prospect.

- Slimhole selection hydraulic designoptimized bottom hole cleaning [12,378 bytes]

- Time trip comparison for common drill pipe sizes [10,235 bytes]

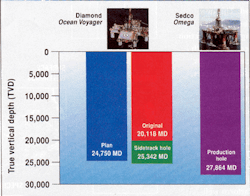

The original total depth (TD) of the well was planned at 24,750 ft measured depth (MD), with a true vertical depth (TVD) of 23,700 ft. Due to deeper than anticipated geologic horizons and a sidetrack situation, the planned (TD) was extended to 28,000 ft MD. Further examination of the operating environment made it clear that an unconventional slimhole drill string would be required.

Drill string load requirements, annular mechanics (fishing), and hydraulics were three of the most critical parameters used to determine that an unconventional slimhole string would be required to drill the final hole section of the well. The design of this string was an iterative, parallel process involving evaluation of hydraulics, fishing, torque and drag, running and handling, and drill pipe specification parameters.

Preliminary torque and drag analysis parameters included using readily available drill pipe, which maintained conventional fishability inside the 7 in. 35 ppf liner, and 5 7/8 in. hole. Mud weight used for the design was approximately 90% of actual drilling weight. Although drilling mud weight was expected to range between 14.6 lb per gallon (ppg) and 15.5 ppg, a value of 13.5 ppg was used to account for potential lost circulation situations. Drill pipe connection make-up torque, and the weaker of pipe body and connection tensile capacities were used for design parameters.

The first iteration used the cited torque and drag results and conservative drilling parameters. Limiting factors, tensile capacity of the API Premium class 4 in. 14 ppf, S135 WT39 drill pipe and hydraulic horsepower, made this design unuseable.

The second iteration focused on the need to maintain fishability and increase overpull capacity without regard to hydraulics. The length of 4-in. drill pipe was minimized and replaced with 3 ½ in., 13.3 ppf, S135 HT38 pipe. To increase the tensile capacity safety margin, the remaining body wall (RBW) width specification was increased to 90% for the iteration.

Maintaining fishability of this string design required removing approximately 1/8 in. of the tool joint OD. This would have been costly and effect overall string strength rendering the design inadequate.

The third iteration continued the focus on fishability, but sought to improve hydraulics limitations of the two previous iterations. A 3 ½ in. XH (4 in. SH) connection on the 4 in. 14 ppf, S135 drill pipe was modeled, significantly improving the hydraulic limitations, and not sacrificing overpull and torque capacities.

With two connections meeting acceptable design criteria, a decision was required on which connection, WT39 or 3 ½ in. XH would be used. The inability to fish effectively at the depths planned made this decision easier. Overall string strength from the WT39 connection was preferred over 3 1/2 in. XH fishability, yielding more applicable drilling and tripping functionality.

The 90% RBW used in the final string design allowed for 57,600 lb of backreaming overpull and 62,300 lb of tripping overpull in 13.5 ppg mud. This worst case, lost circulation scenario, was countered with a potential maximum mud weight of 15.5 ppg at total depth, yielding 74,200 lb of backreaming overpull. These parameters included the modeled drag results and remained within acceptable limits.

Hydraulic design constraints included a 15% safety factor and a maximum operating pressure of 4,250 psi. Annular velocities with an anticipated 15.2 ppg mud weight would be approximately 187 ft per minute (fpm) at a pump rate of 200 gpm and 3500 psi pump pressure. A riser pump was used to help reduce hydrostatic head and lower total system pressure loss. Bit face cleaning and equivalent circulating density (ECD) values remained within acceptable limits with values of 3.0 hydraulic horsepower (hhp) per sq in. of bit face area and 16.2 ECD, respectively.

The extreme depth of the well and the concern for drill string reliability demanded special tubular inspection processes. Drill string component inspection criteria was related directly to the design model's predictions for torque and tension parameters. T.H. Hill Associates Standard DS-1trademark Category 5+ was used to inspect the 4-in. drill pipe. To guarantee the 90% remaining body well (RBW), full length ultra-sonic (FLUT) testing was used. An unexpected finding was that 860 out of 867 joints met at least a 95% RBW, which resulted in an additional 27,600 lb of tensile capacity to the drill string.

With the final engineering design finalized, attention could be directed to the rig and operations planning. Drill pipe handling, tongs, and elevator lifting functionalities were addressed. The use of 4 in. drill pipe with a WT39 connection raised questions on connection make-up and break-out times.

Evaluation of existing rig tong equipment needed to be performed to assess functionality. Previous hydraulic power tong experience had yielded faster handling times with 3 ½ in. drill pipe. This experience and the added rotation required for make-up of the WT39 connection made the upgrade to hydraulic power tongs necessary. Running speeds for the 4 in. drill pipe were estimated at 40% - 60% faster than manual tongs.

Elevator selection received extra attention to accommodate the unconventional drill string design. A standard elevator used with the 4 in. 14.00 ppf S135 drill pipe and WT39 tool joint resulted in excessive stress placed on the elevator 18intergral load-bearing surface. However, the lifting rating was comparable to the yield strength of the S135 drill pipe, making it an acceptable compromise.

Slight mis-alignment of this WT39 tool joint in the elevator created a hanging situation during break-out of the pipe. This could have resulted in excessive thread wear and possible future downhole failure. To prevent this, a lift-out guide was designed and constructed to re-align the pin with the box.

Comparisons of projected versus actual torque and drag revealed very similar values. The result was proportional to the difference in the coefficients of friction (COF) for cased and open hole. Back calculation of COF for open and cased hole with T.H. Hill Associates DS-1trademark Drill String Spreadsheet 1.0 software, using the actual loads recorded on the well, resulted in lower than projected loads being realized. This was a result of the conservative approach taken in the original designs.

Inspection of the drill string upon the completion of the project revealed approximately 1.0% failure rate on all connections. This is in line with the historical performance of the WT39 thread and more favorable than the average API reject rate of 15%.

Unique problems demand unique solutions. The willingness to try new approaches, design conservatively, and evaluate continuously allows for quick and effective results to be realized.

Reference

Prater, T., Everage, S., Greenip, J., Adams, B.,"Drill String Considerations for Gulf of Mexico's Deepest Well (27,864 ft), OTC Paper 52822, SPE, Offshore Technology Conference, May, 1999.

Copyright 1999 Oil & Gas Journal. All Rights Reserved.