Permeability and porosity straight from drill cuttings

A fast and direct approach for reservoir petrophysical characterization

R. Lenormand

P. Egermann

IFP Exploration & Reservoir Engineering

A true permeability log is obtainable for the first time just a few days after drilling a well. An original technique, Darcylog, developed by the Institute Francais du Petrole, is based on a measurement of permeability on cuttings collected during drilling. Contrary to existing methods, the permeability is not derived from a correlation [porosity or nuclear mag-netic resonance (NMR) relaxation] but is determined directly by measuring the press-ure and the flow rate during a displacement.

When cores are not available, this method is the only way to obtain values of permeabilities that can be used directly for reservoir characterization and also to calibrate other logs. In addition to permeability, the measurement of porosity on the same samples is provided. Since only small size cuttings are considered, it can be reasonably assumed that the cuttings travel with the mud and consequently lag time correction applies.

The method is much cheaper than coring, because the only additional task consists of collecting a small volume of cuttings in the shaker at regular intervals and in sending them for measurement, even without cleaning. The method is fast, since cleaning and drying of cuttings are faster than for cores. Including the shipping, results can be provided within a few days. The method is accurate in the classical range of reservoir permeabilities (<1 Darcy).

Since the method is completely new, an explanation of its principle to demonstrate that measuring the permeability on cuttings as small as 1 mm is needed. A recall of the state of the art for permeability measurements on drill cuttings and a brief description of the IFPs' method are necessary for a better understanding.

null

State of the art

Core analysis in the laboratory is the most reliable technique to measure permeability, but it is rather expensive (coring, rig time, transportation, measurement). The data are available several weeks after drilling. Well testing provides information on the extension and the connectivity of the reservoir and gives an average permeability value. A more accurate permeability profile can also be obtained with the MDT technique (Modular Dynamics Tester), run with wireline, with a spatial resolution of the order of meters. NMR logging is now widely used to derive a fast evaluation of the permeability profile along the wells. However, the NMR tool is sensitive to the pore size whereas permeability is sensitive to the throat size. Hence, the permeability evaluation is obtained through empirical laws, which need to be calibrated according to the reservoir rock and fluids in place.

The cuttings are routinely used by the mudloggers to build the "masterlog" where the geological description of the drilled formation is reported. Hydrocarbon presence is also detected from cuttings in order to identify the reservoir zones. Although rock from cuttings comes directly from the reservoir, few attempts at using cuttings for permeability characterization have been reported in the literature. The main drawbacks of the existing methods are either a heavy conditioning prior to measurement, or a range of application limited to the extremely low permeability.

Other methods use empirical correlations to derive permeability from properties related to the pore size distribution, the pore connectivity or the spatial correlation between the pores. These parameters are evaluated from capillary properties (mercury porosimetry), NMR or image analysis. The main drawback of these methods is that the permeability is not measured directly and that time, preparation and calibration are needed before getting the results.

null

Permeability measurement

The main problem is to establish a flow in the rock itself rather than in inter-cuttings space. In the Darcylog method, the flow of a liquid into the cuttings is made possible by compression of the residual gas initially trapped inside the cuttings. The originality of this method is to combine a viscous liquid for measurable pressure drop and a trapped gas for compressibility. The viscosity of the liquid can be adapted to the range of permeability to measure. This method, developed by Lenormand and Egermann in 2000, is incorporated into several IFP patents.

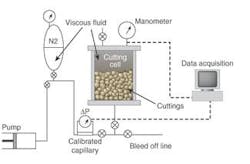

Initially, the cuttings are introduced into the cuttings cell, at which time the system is filled with viscous oil using a pump at atmospheric pressure. The injected oil displaces the gas located in the inter-cuttings space and also invades the cuttings by spontaneous imbibition. At the end of this displacement, gas is trapped inside the cuttings as residual, disconnected gas. The cuttings cell is then connected to a cell containing viscous oil at 10 bars. During the displacement, the pressure and rate of injection are recorded. The rate of invasion depends on the fluid viscosity and rock permeability.

null

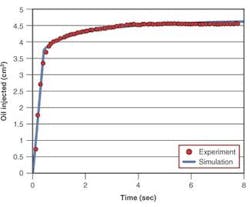

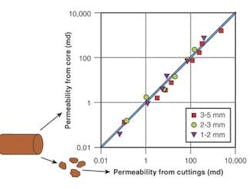

The permeability is calculated by using a numerical model based on the equations describing the flow of a viscous fluid into a compressible medium of spherical geometry. Several tests were performed on cuttings obtained by crushing cores of known permeabilities so as to validate the methodology. Several samples of carbonates and sandstones were used to investigate a wide range of permeability up to 1 Darcy.

When the cuttings are received in the laboratory, they are cleaned, dried, and sieved in the 1-2 mm or 2-3 mm range to obtain a volume of around 2 cu m necessary for permeability measurements.

null

The porosity and the grain density from cuttings are also measured using the classical gas expansion method but adapted for very small volumes. For a given sample, the K-phi measurements and interpretation take less than one hour.

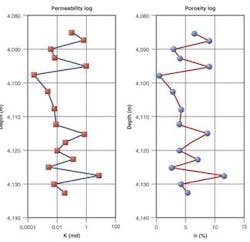

The final result is a plot of formation porosity and permeability versus the well depth. Since we consider only small size cuttings, we can reasonably assume that the cuttings travel with the mud and consequently that the lag time correction applies.

References

Egermann, P., R. Lenormand et D. Longeron: "A fast and direct method of permeability measurements on drill cuttings," SPE 77563, ATCE, San Antonio, USA, 2002.

Fleury, M.: "Validity of permeability prediction from NMR measurements", n° GERM Annual Meeting, La Pommeray, France, 14-18 May 2001.

Lenormand, R. et P. Egermann: "Méthode pour évaluer des paramètres physiques d'un gisement souterrain à partir de débris de roche qui y sont prélevés," French Patent, 2000, 2002.

Luffel, D. L.: "Devonian shale matrix permeability successfully measured on cores and drill cuttings." Gas Shales Technology Review, vol 8, 2, pp 46-55, 1993.

Santarelli, F. J., A. F. Marsala, M. Brignoli et al.: "Formation evaluation from logging on cuttings." SPE Reservoir Eval. & Eng., June, pp 238-244, 1998.

For additional information, contact: http://explo-re.ifp.fr/IFP/en/files/rechercheindustrie/darcylog.pdf.