Cognite, Neptune develop hybrid AI well modeling and monitoring application

By Moe Tanabian, Cognite

Neptune Energy selected Cognite to deliver a new online well modeling and monitoring solution for operational wells on Cygnus in the UK with the objective to deliver near-real-time surveillance of well model performance for operational wells. Cognite automated and streamlined the existing, manually intensive workflows to shift prioritization from selecting candidates for detailed analysis to value-adding decision-making and actioning.

The challenge

The status quo at Neptune Energy recognized an opportunity to streamline the way its domain experts manipulated and analyzed data. Legacy tools (i.e., Excel) provided limited automation, causing engineers to spend time on repetitive tasks. Additionally, maintaining a centralized, versioned repository for simulator models was difficult as interactive analysis was performed in a siloed setting.

What is also becoming better understood is the importance of capturing the value that can be extracted from an organization’s data—a commodity that exists in infinite supply. Data are the great untapped resource, and a wealth of information is available that can unlock dramatic improvements in safety, efficiency and productivity.

The solution

Neptune Energy leveraged Cognite Data Fusion to develop a hybrid AI well modeling and monitoring application. Through a native integration with the PROSPER well and pipeline modeling simulator, automation was introduced to perform validations, increase the number of interpreted datapoints, and reduce time-consuming data manipulation steps and reporting cycles to achieve higher volumes of broader surveillance and higher quality assessments. The Cognite Simulator Connector integrates the PROSPER simulator with Cognite Data Fusion.

There are five PROSPER calculations included in the Well Model Real Time Monitoring project:

- Nodal analysis: Calculates the flow rates of well fluids to determine well potentials and analysis sensitivities

- Choke performance: Estimates the gas flow rate by solving PROSPER choke performance calculation

- Lift curve solution: Estimates the gas flow rate using the tubing performance curve

- Inflow performance: Estimates the gas flow rate using the inflow performance curve

- Bottomhole pressure: Estimates the bottomhole pressure when no sensor is available

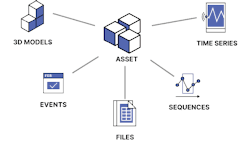

The Simulator Integration services in Cognite Data Fusion include a model library and version tracker that gives users complete control over simulation files and ensures up-to-date file access.

Engineers use the model library to schedule calculations or run them on demand. After the calculation is finished, output values are read from the simulation model and saved to a time series.

Neptune’s solution includes visualization tools to illustrate each simulation’s status and results to ensure accuracy. Calculation details are stored in Cognite Data Fusion’s no-code interface for further analysis.

The scalable solution enables Neptune Energy to add more wells in the future using data models.

Each time a new well is added, Cognite Data Fusion automatically matches corresponding sensor data. Thus, the Industrial DataOps platform provides a simple, automated solution for deploying and managing wells at scale.

Value realization

The Cognite Data Fusion solution went live in 2021, improving Neptune Energy’s ability to perform analytics on well models’ accuracy and increasing awareness across different departments.

By fully adopting the solution, the Cygnus team has an automatic model health tracking system and a library of highly accurate models. This enables a variety of surveillance and optimization solutions that optimize the operation of Neptune Energy’s assets.

The Hybrid AI workflows in Cognite Data Fusion helped Neptune reduce time spent on data manipulation, mining, analysis and validation while near-real-time surveillance increased proactive decision-making.

A modern industrial data foundation allows energy companies to progress their digital maturity while building, operationalizing and scaling data-driven solutions. Cognite Data Fusion enables asset-heavy enterprises to deliver tailored, scalable solutions across users and facilities to harvest the value potential of digital investments and create a more efficient industrial future.

About the author: Moe Tanabian is the chief product officer at Cognite. Tanabian has been driving innovation at scale for nearly three decades, particularly in the areas of software products, AI, ML and IoT. Before joining Cognite, he held various leadership positions at Microsoft, Samsung and Amazon. Tanabian holds a master’s degree in systems and computer engineering from Carleton University in Ottawa, Ontario, and an MBA from the School of Business at Queen’s University in Kingston, Ontario.

03.30.2023