OTC 2022: Technip Energies shares how FLNG applies to energy transition

By Ariana Hurtado

A floating liquefied natural gas (FLNG) facility is moored above an offshore natural gas field. FLNG technology is designed to overcome the challenges of geographic, technical and economic limitations of offshore fields and help accelerate the development of the natural gas resources from those underwater gas fields.

Lorenzo Disaro, business development manager FLNG with Technip Energies, discussed the company’s FLNG success and solutions and how this technology applies to the energy transition, specifically reducing the CO2 footprint, during an Offshore Technology Conference (OTC) presentation Wednesday morning.

Technip Energies has more than 50 years of experience with LNG, and FLNG is a mature technology that is fully under control by the company, which Disaro boasts is “very successful in the FLNG space.”

Offshore FLNG provides “an alternative to traditional onshore LNG plants,” according to Technip Energies ’s Offshore LNG brochure. “As it is not necessary to deploy onshore infrastructures, offshore LNG avoids the need to build and operate long-distance pipelines. This floating facility offers a fast and environmentally friendly solution to the monetization of offshore stranded gas fields or associated gas from oil production.”

Technip Energies offers multiple solutions for offshore, near-shore and quayside.

“We have solutions for other types of FLNG, which also can be applied to improve LNG production, provide more energy to the market and also to monetize associated gas, which today is a vast problem in the emissions space,” Disaro said. “And we have technologies to reduce emissions on the asset itself.”

Key project references

Technip Energies provides entire project needs from early concept definition to startup. The company also offers delivery for integrated engineering, procurement and construction (EPC) and installation contracts, which includes offloading services that ensure the safe transfer of LNG between offshore producing facilities and LNG carriers.

The company has gathered vast experience with several EPC projects, such as Prelude FLNG, Petronas Satu FLNG and Coral South FLNG, in addition to 40-plus engineering studies from concept definition to EPC.

Technip Energies boasts a 600,000-ton displacement with its Australia-based FLNG Prelude, which is the world’s heaviest floating vessel, according to the company. Technip Energies was awarded a contract for Shell’s Prelude in 2011, with delivery in 2018. Technip Energies led the consortium with Samsung Heavy Industries to complete a master agreement for multiple FLNG facilities over 15 years.

“[Prelude] delivered the world’s first qualified FLNG with a capacity of 5.3-Mtpa liquids, and [it was] the largest floating steel structure ever built designed to withstand the harsh cyclone conditions,” according to the company.

Technip Energies also touts it delivered the world’s first FLNG—the PFLNG Satu in Malaysia. It was designed by consortium leader Technip Energies and fabricated at the Daewoo Shipbuilding and Marine Engineering yard in South Korea. PFLNG Satu achieved the first offshore production of LNG in April 2017 for client Petronas.

Technip Energies was also awarded a turnkey contract, including a floating facility and SURF in deep water, for Eni’s Coral South FLNG in 2017. The FLNG unit is located in Mozambique and is the first FLNG project arranged with project financing. Coral South has a 3.4-Mpta liquids capacity.

Today the company services include

- Design and execution with multiple gas pretreatment and liquefaction processes;

- Design of small-scale to very large scale (up to 12 Mtpa) LNG production capacity FLNG;

- Process from very lean to rich gas (condensates and LPG can also be produced);

- Internal, external turret moorings or spread moorings;

- HSE design to propose mixed solutions (e.g., safety gaps, fire walls);

- Execution experience with gas and steam turbines and large electric motors (water and air cooling for deep or shallow water applications); and

- Side by side, tandem or parallel LNG offloading depending on the environment.

FLNG solution to reducing emissions

“So how can FLNG be a solution for reducing the CO2 footprint of the energy industry? The first step is to reduce the CO2 that you actually emit during the construction,” Disaro said.

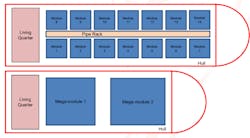

One solution he highlighted was the company’s fairly new Megamodule concept and model, which aims to reduce project costs and schedules. Originally introduced at OTC 2019, the concept allows operators to produce more LNG with the same amount of space as traditional projects.

Megamodule is designed to optimize the use of available deck space; offer maximum construction and commissioning at ground level; offer possible construction of hull and topsides in different locations; and expand the number of yards available for construction.

“This is a way to reduce CO2, not only to reduce the capex and the costs, but actually the concept of the design of the topside into fewer two or three larger and heavier modules, as opposed to the conventional topside module to do the same function,” Disaro said. “We offer larger modules, which would integrate similar functionalities, and that would actually reduce the footprint of the FLNG itself, so we could improve intensification of the plant.”

This would result in less steel and less construction, therefore less emissions and reduced construction costs.

Disaro added, “The company also offer other solutions to reduce the CO2 and GHG [greenhouse-gas] emissions onboard FLNG, such as CO2 capture from feed gas and direct capture from exhausts, CO2 treatment and injection, power and process efficiency, fugitive emissions control, and air-cooling improvement with more efficient heat exchangers using patented DIESTA tubes technology.”

About the Author

Ariana Hurtado

Editor-in-Chief

With more than a decade of copy editing, project management and journalism experience, Ariana Hurtado is a seasoned managing editor born and raised in the energy capital of the world—Houston, Texas. She currently serves as editor-in-chief of Offshore, overseeing the editorial team, its content and the brand's growth from a digital perspective.

Utilizing her editorial expertise, she manages digital media for the Offshore team. She also helps create and oversee new special industry reports and revolutionizes existing supplements, while also contributing content to Offshore's magazine, newsletters and website as a copy editor and writer.

Prior to her current role, she served as Offshore's editor and director of special reports from April 2022 to December 2024. Before joining Offshore, she served as senior managing editor of publications with Hart Energy. Prior to her nearly nine years with Hart, she worked on the copy desk as a news editor at the Houston Chronicle.

She graduated magna cum laude with a bachelor's degree in journalism from the University of Houston.