The Offshore Technology Conference (OTC) returned to Houston in mid-August. While the COVID-19 pandemic continues to present challenges, this year’s event brought offshore energy industry professionals, exhibitors, and students together in person and online.

This year, 14 technologies from 13 companies from around the world received the Spotlight on New Technology Award. Five of the 13 firms also won the Spotlight on Small Business Award, which honors companies with less than 300 employees.

Cindy Yeilding, chairperson, OTC board of directors, said: “At its core, energy is a technology-based industry that relies on scientists, engineers, computer programmers, and other highly skilled professionals to drive the future of energy forward. The companies recognized by the Spotlight on New Technology award are making energy development more efficient and sustainable and will be at the forefront of the next generation of offshore energy.”

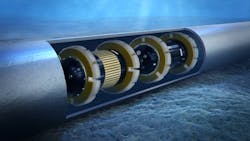

Saipem won the award for its Hydrone-R underwater intervention drone (UID). The Hydrone-R is part of the company’s Subsea Robotics Innovation Program conceived to support remote, low-carbon, and safe operations in the offshore energy market. Developed and engineered by Sonsub, the company’s center of excellence for subsea technology innovation, is a UID capable of performing construction works as well as autonomous inspections on a range of subsea assets thanks to the embedded, proprietary artificial intelligence features.

The vehicle can remain underwater uninterruptedly for up to 12 months, hosted on a subsea docking station, either proprietary or provided by the customer for battery recharging and mission data uploading/downloading. This makes it the first-ever resident subsea drone, the company claimed.

When set in resident mode, the drone can be remotely supervised and operated from onshore via a remote control room, leveraging on through-water communication links. As an alternative, it can work in fully autonomous mode within an intervention area of +10-km (6-mi) radius. Larger distances can be covered by introducing additional intermediate subsea docking stations, the company said.

Subsea 7 and its autonomous subsidiary Xodus Group received the award for the Subsea 7 nano engineered sensor platform (NESP). The platform can continuously monitor fatigue and corrosion offshore. The wireless nano-technology sensor can be deployed efficiently and easily across any operating asset.

Subsea 7 NESP, which requires no power supply or batteries, offers a scalable, cost-effective, zero maintenance solution to extend asset life and improve uptime.

Dril-Quip won for its BADGeR gas-tight casing connector. According to the company, the system delivers superior fatigue performance and anti-rotation keys to allow for hands-free make-up, leading to faster connection times and allowing for fewer rig personnel working in the high-risk red zone.

TechnipFMC and Halliburton were honored for their Odassea subsea distributed acoustic sensing system. The fiber optic sensing system is said to integrate hardware and digital systems to improve subsea reservoir monitoring and production optimization. Halliburton is responsible for the fiber optic sensing technology and analysis for reservoir diagnostics, while TechnipFMC provides the optical connectivity from the topsides to the completions. The overall service is said to allow operators to speed up full-field subsea fiber optic sensing, design, and execution.

Halliburton also won for the DynaTrac real-time wireless depth correlation system. The system is said to eliminate uncertainty in tool position without the need for wireline or work string manipulation while tracking movement of the bottomhole assembly.

Rocsole Ltd. earned the award for its Deposition In-Line Inspection (DILI) system. The system uses a non-nuclear tomographic technology to inspect pipelines for deposition build-up thickness, type, and location. This safe and non-invasive sensor works in various process environments without a need for production interruption and enabling fast reporting of results with AI/ML-based data processing.

The Kuopio, Finland-based company also earned the OTC Spotlight on New Technology Small Business Award.

HYTORC received the award for the J-Washer. This lock washer is used to maintain joint integrity under dynamic conditions such as thermal cycling, rotating machinery, and transportation. The patented J-Washer provides all the safety, quality, and speed benefits of the standard HYTORC Reaction Washer and now offers the ability to lock fasteners tight. The Mahwah, New Jersey-based company also earned the Small Business Award.

Oil States Industries earned the award for the Merlin deepsea mineral riser system. This fast, hands-free riser system is designed to collect polymetallic nodules 6,000 m (19,685 ft) below the surface of the Pacific Ocean.

Schlumberger received the award for the DrillPlan coherent well construction planning solution. This is a collaborative cloud-based space that empowers data-driven insights and accelerates the delivery of an efficient and optimal drilling program. It is said to increase planning efficiency and enhance well designs through automated end-to-end workflows, cross-company and cross-domain collaboration, instant design validation, and integrated offset knowledge.

Oliden Technology was recognized for the LithoFusion azimuthal density and porosity logging-while-drilling tool. It delivers azimuthal density, neutron porosity, and borehole images. High vertical resolution logs and imaging provide the best insights for quantitative fluid and mineralogy analysis, geological structures, borehole stability, and well placement. Designed for both oil base and water base muds, the tool enables geosteering and formation evaluation while drilling through dipping formations. The Stafford, Texas-based company also won the Small Business Award.

Siemens Energy won two Spotlight Awards. This first is for Asset Performance Management for Oil & Gas (APM4O&G). This delivers a diagnostic and decision-support solution for oil and gas equipment, enabling a step-change in how offshore operators manage their assets. By continuously comparing real-time equipment operational data against models and running automated diagnostics, operators can forecast performance, pre-empt failures, and conduct reliability-centered maintenance.

The second is for the MyFleetRisk data-driven risk management platform. It leverages real-world engineering expertise to quantify and visualize risk profiles of its oil and gas customers’ gas turbine fleets. The platform provides real-time visualization, prioritization, and recommendation of mitigation action.

INGU earned the award for the Pipers 2.8 pipeline inspection tool. The self-serve, free-floating, micro multi-sensor solution works in operational conditions, delivering conditional-critical data related to leaks, deposits, and wall condition. According to the company, Pipers improve planning, decision-making, and operational control, while reducing the risk of failure. The Calgary, Alberta-headquartered company also received the Small Business Award.

Techni received the award for the PACT electric pressure control actuator. It is designed to be a drop-in replacement actuation system that features a patent pending failsafe mechanism. The Norwegian company also earned the Small Business Award.

OTC is scheduled to return to NRG Park from May 2-5, 2022.

About the Author

Jessica Stump

Editor

Jessica Stump is editor of Offshore Magazine. She uploads and writes news to the website, assembles surveys and electronic newsletters, and writes and edits articles for the magazine. She was the summer editorial intern at Offshore in 2009 and 2010 before joining full time in April 2011. She has a journalism degree from Texas Tech University.