Collaboration increases pipelay technology development

Alasdair Cowie, Cortez Subsea

Welding is the predominant method for fabricating pipe systems across the subsea industry. But there are several applications where traditional welded pipe connections become inefficient, uneconomic, or impossible.

Various pipe-joining technologies have been developed over the years to increase pipeline lay speed and reduce installation cost. It is particularly appealing to find an alternative to the welding process which is widely regarded as the bottleneck for pipeline installation cost reduction.

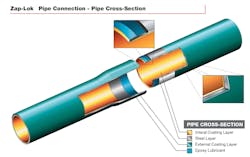

Cortez Subsea designed and patented its Modular Pipelay System (MPS) to offer a weld-free, semi-autonomous pipelay process which is coupled with mechanical connectors to offer an efficient and economical alternative to welding. Mechanical interference connectors, such as the NOV-Tuboscope Zap-Lok connector, are formed on carbon steel pipes and combined with external and internal coating products to produce a break-free subsea pipeline system.

The MPS can lay up to 5 km (3 mi) of pipeline per day using mechanical connectors in comparison to conventional pipelay which achieves an average of 1.5 km (0.93 mi) a day. This means less vessel time and less crew and a cost saving of up to 30%. Also, by embracing internal plastic coating technology in concert with Zap-Lok it is possible to use the pipe wall body for on-bottom stability and dispense with expensive concrete weight coating. This reduces raw material costs and offshore rates further due to the increase in pipe that can be stocked on the pipelay vessel.

Mechanically connected pipe is proven. More than 7,000 km (4,350 mi) of subsea hydrocarbon pipelines have been installed worldwide using Zap-Lok with zero recorded failures in operation of over 70,000 joints.

The company has also worked to take the Stinger Deployed Diverless Connector (SDDC) to market in partnership with AFGlobal. It is an example of using proven technology to create a new product for a specific application. The SDDC conducts pipeline tie-ins without the need for divers. The solution is driven by the AFGlobal Retlock clamp technology. This two-bolt clamp can connect to mono and multi-bore, is suitable for vertical and horizontal applications, and it has been proven effective in more than 1,600 offshore applications. A compact, lightweight design with continual leak-monitoring system, it is the ideal basis for the SDDC system which can be deployed through the stinger of a pipelay vessel. It facilitates the direct connection to flexible risers at either end of the pipeline. This reduces the subsea infrastructure required and removes critical path processes, such as metrology and manufacture of jumper spools. This means installation can be completed faster and with a lower hardware cost.

Collaborative partnerships are vital to the success and development of technology. Innovation needs collaboration. Being partnered with organizations in and out of the sector that support, drive, or lead the development of a product or service can aid the success of businesses.

That is why Cortez Subsea refers to its ‘collective technology toolbox’ to solve operational challenges. The company consults this when it is faced with projects which require a carefully curated technology mix to satisfy challenges.

Vestigo Petroleum is installing a new wellhead platform (WHP) in the Berantai field offshore Malaysia to increase production. The export of this platform will require a 12-in. pipeline to the FPSO Berantai. In addition, a fiber optic communications cable is to be installed alongside to allow control of the unmanned WHP. The WHP is a Zee-Pod Structure which allows for a quick installation but leads to several design issues when installing an export pipeline. A safe and cost-effective technology mix is required to achieve the operator’s goals efficiently. The use of mechanical connectors and flexible risers with the SDDC will enable the company to deliver lower cost and risk.

More and more the industry wants to create an environment in which we are not only safe but proud to work in. The advancement of new technology is one way we can ensure we meet and exceed increasingly stringent environmental targets.

The International Maritime Organization has adopted regulations and mandatory energy-efficiency measures to address the emission of air pollutants from ships. The transition to a lower-carbon future is under way and the oil and gas industry will have an important role.

Among many other efficiencies the MPS, mechanical connectors and the SDDC system reduce the reliance on large vessels as well as save time to significantly reduce our carbon footprint.

New technology is being created, tested, and applied in response to the needs of the industry. That being said, smart application is of absolute importance. Conventional thinking is natural but the need to reduce cost, improve safety, and protect the environment requires change. •

The author

Alasdair Cowie has spent more than three decades working in the subsea and marine sector of the energy industry. After serving an apprenticeship with the Ministry of Defence and working offshore he moved into onshore management roles. He quickly moved up the ranks to senior management positions with Saipem and Kvaerner Oilfield Products before becoming managing director of TSMarine, a subsea intervention and construction support company. In 2010, Alasdair founded Cortez Subsea, where he is managing director.