DeepDriver subsea hammer provides low-cost piling solution

In the current subsea market environment, the overriding imperative to reduce costs is driving oil and gas companies, deepwater drillers, pipeline operators, installation contractors, and other service providers to seek innovative ways to lower capital and operational costs.

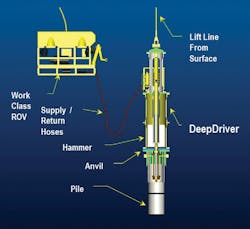

DeepDriver is commercializing a recently patented subsea piling hammer that is water depth independent and hydraulically powered by an ROV. The company says that this technology will provide the oil and gas industry with a new and far more cost-effective method to drive small-to-medium diameter piles at any water depth with savings on a typical subsea piling project estimated at greater than 50% when this size hammer can be used.

DeepDriver is commercializing a recently patented subsea piling hammer that is water depth independent and hydraulically powered by an ROV. (Courtesy DeepDriver)

DeepDriver says that the availability of the technology will enable new designs of subsea equipment and provide lower costs; simpler and faster installation; and intervention and stabilization methods. The system is a compact package that eliminates power packs, multiple winches and umbilicals, thus allowing rapid deployment on smaller, less expensive and more readily available multi-service type vessels.

The first generation DeepDriver hammer is rated at 60kJ (kilo Joules) impact energy, and a 100kJ hammer is planned. While the system can drive piles from 12-in. to 72-in. diameter depending on soil conditions, most projects are expected to use piles with 16-in. to 36-in. diameters.

The company notes that the system will allow the use of driven piles in a variety of applications not considered practical today. According to the company, the system can replace current methods that involve jetting, cementing, etc.; and, depending on soil conditions and pile size required, it can enable cost-effective alternative solutions to costly gravity bases and suction piles. Besides conventional subsea piling applications, the system is also designed to enable new and improved applications such as hybrid mud mats using pin piles, pre-installed well conductors, pipeline route stabilizations, secondary pipeline stabilizations (to prevent pipeline “walking”), pipeline free span rectifications, and other innovative inspection, repair and maintenance (IRM) applications.

For example, pre-installation of well conductors before arrival of the deepwater drilling rig is a high-value application where the new system is a cost-effective solution. A leading subsea mooring company that has successfully pre-installed deepwater well-conductors using a conventional subsea hammer has been collaborating with DeepDriver on a potential project in the US Gulf of Mexico. Because the US Bureau of Safety and Environmental Enforcement currently requires a complete topside BOP inspection after every well is drilled, the economic benefits for pre-installed conductors in the GoM are quite significant if two BOP stacks are available on the drilling rig and even more compelling in other offshore regions where one BOP stack is typically used.

For this project, it was concluded that if at least four well conductors are pre-installed (batch set) using DeepDriver on each drilling campaign, an installation cost per conductor of $350,000 or less can be achieved in the GoM, which is less than 50% of the cost of using a deepwater drilling rig with two BOP stacks at contracted dayrates. In this case, at least $5.6 million could be saved on the total cost to install 14 well conductors. In addition, driven well conductors provide similar strength and stability to drilled and cemented conductors with significantly more favorable economics and less soil disturbance during drilling operations. When compared to jetted conductors, a driven conductor provides significantly greater strength and stability throughout the entire life of field.

The company says that conventional subsea piling hammers are larger, depth dependent, and far more costly to deploy and operate due to expensive and lengthy mobilizations and the need to be deployed from larger and significantly more costly deepwater construction vessels, which are also less readily available. Conventional subsea hammers use umbilical hoses for power and air that is supplied from the vessel, thus requiring far more complex deployment systems, more persons on board, and an ROV is also needed to support subsea operations. Although there are deepwater hammers with significantly greater impact power than DeepDriver, these hammers are at least three times heavier and are often too large to effectively drive small to medium diameter piles in deepwater.

The company says it has built and successfully tested the full scale hydraulic system that powers the 60kJ hammer. The engineering design is essentially complete and the timeline to complete building and field testing the first article 60kJ hammer will require no more than 12 months once adequate funding is available to proceed. The company says that it is presently engaged in discussions with leading offshore industry companies that have expressed interest in providing the financial sponsorship and support needed to commercialize the technology.

William Zakroff, CEO of DeepDriver says that: “DeepDriver was invented and engineered by co-founder and CTO James Adamson P.E., a world renowned technical authority on ROVs and ROV tooling. Once the DeepDriver hammer has completed field trials, the initial focus will be on IRM projects as the subsea industry recovers.”

Bruce Crager, Executive Vice President of Endeavor Management, said that: “The subsea industry is facing huge challenges to reduce costs, and DeepDriver provides an innovative tool that addresses this challenge.” Endeavor Management is an international strategic advisory firm headquartered in Houston that is assisting DeepDriver in its development efforts.