Rigless drilling tool enters testing phase

Badger Explorer - a game-changing drilling technology, according to Badger Explorer ASA’s CEO Kjell Erik Drevdal - has moved off the drawing board and entered the testing phase. It should be proven and ready for the market by late 2008.

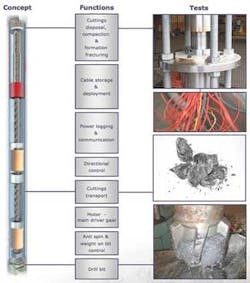

This is a tool designed to drill into the subsurface and to perform logging operations without the need of a drilling rig or well construction. Instead, the patented probe is self-burying, sealing the path behind it as it drills ahead to prevent any release of hydrocarbons to the surface. It is destined to remain in the subsurface.

The tool connects to the surface by a power and communications cable spooled inside. The power is used by the electric motor for driving the drillbit, for cuttings disposal, and for running the suite of formation logging sensors. A directional device ensures that the probe maintains a vertical heading.

This technology, which can be deployed from a standard offshore support vessel with a crane and ROV, is claimed to offer substantial cost-savings compared with conventional rig-drilled wells. In water depths of up to 1,000 m (3,281 ft), the cost is around one-third, according to Drevdal. The saving increases with rising depth, down as low as one-tenth of normal drilling costs below 1,000 m of water.

Funding commitment

The original idea was conceived in the late 1990s by Sigmund Stokka, a researcher at Rogaland Research (now renamed IRIS). The method is protected by patents awarded to the company in Norway in 2002 and in the US in 2006.

Badger Explorer ASA was established in 2003 and has drawn enthusiastic acceptance for its concept. In response to its proposal for a NKr 25 million ($4 million) development project, it has raised NKr 7 million ($1.1 million) from the Research Council of Norway and funding in equal shares from project partners ExxonMobil, Shell and Statoil. The company itself has put up NKr 3 million ($490,000).

Preliminary tests were sufficiently promising to enable the company to raise commitments in the investor market. By late 2005, it was in a total cash equivalent position of around NKr 100 million ($16.26 million). Late this spring, it plans a listing on the Oslo Stock Exchange.

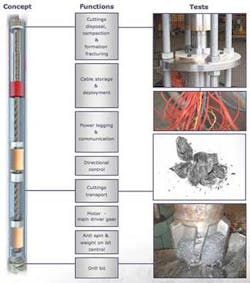

In April, the first full-scale system function test of a simple Badger Explorer prototype is scheduled to be performed at a shipyard in Stavanger. Later in the year, a full-scale prototype will be built and tested onshore. In this test, the tool will be connected to a power supply and will undertake drilling and self-burial operations. Offshore testing will be carried out in 2008, after which Badger Explorer will be ready for commercialization.

The technology essentially is simple, according to Drevdal, but includes novel elements. One of these is the cuttings disposal function, whereby the cuttings, after being transported through the tool to the rear, are compacted, continuously filling in the bore-hole behind the tool in small increments. The small volume of cuttings which remains is disposed of by fracturing the formation around the borehole and pressing the cuttings into these fractures.

Details of how this function works are confidential, but Drevdal says tests have confirmed that the material is sufficiently compacted to withstand hydrocarbons under high pressure.

The first generation of the Badger Explorer tool will have a 5-in. (127 mm) diameter body about 25 m (82 ft) long, fronted by a 6-in. (152 mm) drill-bit. The length is partly determined by the length of cable to be spooled inside - 25 m (82 ft) provides cable capacity to drill down to 3,000 m (9,842 ft), which represents 70-80% of the prospective market.

Eventually power should be supplied from a station on the seabed, so that once the probe is ready to start drilling, no vessel assistance will be required. The operation will be controlled from a remote location, to which the data will be transmitted via a surface buoy. However, for the first generation, vessel-assist will be needed for power supply and data collection.

Apart from wildcat exploration, the tool also can be used for mapping structures around producing fields to explore for additional reserves - this could be its first application, Drevdal says. In this case, power probably would come from a production platform, to which the data would also be transmitted.

The project has benefited from the close involvement of the oil company sponsors, who are on the steering committee. Their participation also will help in liaising with the authorities, for the Badger Explorer technology is so innovative that rules do not as yet exist to regulate its use, Drevdal says.

Meanwhile the company has come across a novel drilling technique known as Plasma Channel Drilling (PCD) which might provide an alternative to rotating bit technology as a backup solution. The PCD technology is so interesting that the company has decided to develop it for other applications in the drilling and well maintenance market segment.

A NKr 7.6 million ($1.2 million) development project has been set up to further develop and test a prototype built and demonstrated at the University of Strathclyde in Scotland, with which Badger Explorer has signed an exclusive licensing agreement. The technique could be handy in removing scale deposited in production wells, says Drevdal.