Sweden: Treatment process could cut contaminated waste to 5% of its original volume

Jennifer Pallanich Hull

Technology Editor

While the oil industry tries to show off its green side, Swedish company Studsvik RadWaste has come up with a process to treat one element not normally discussed publicly: radioactivity.

"The oil industry has enough trouble with its environmental profile," said Dr. Maria Lindberg, project manager at Studsvik RadWaste. She is one of the forces behind the company's breakthrough process of treating scale:

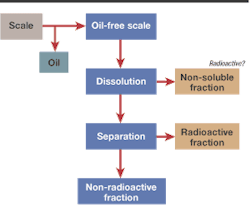

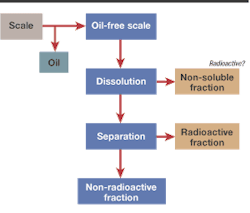

•The pipe or component is de-scaled, i.e., the scale is removed with high-pressure water rinsing, then collected in drums or other vessels

•The metal can be re-used elsewhere in the oil industry, directly free released as scrap, or melted as radioactive material. The method chosen is dependent on the legislation for the country concerned

•The scale is treated with the same Studsvik process. The barium and radium are separated, and the radioactive part packed for final disposal.

The company is proposing its method, which minimizes the volume of waste that must be stored, as one way the oil industry can polish up its image.

Regulations for radioactive disposal and storage vary by government, and that's one of the challenges facing the company, Lindberg said. Studsvik RadWaste is seeking international harmonization of regulations. It believes the global radioactive regulations should be kept simple, in line with its own concept: treat the waste, minimize its volume, and store it.

Space was not at such a premium when repositories were originally built. But with the oil companies' continued drilling into bedrock, which can feature radioactive elements – in addition to mounting waste from the still-growing nuclear industry – a way had to be found to slim down the volumes headed for long-term storage.

"It's not an option to put containers by containers by containers (of radioactive waste) in the ground," Lindberg maintained.

Radioactivity removal from scale

Studsvik RadWaste has focused on separating the radioactive portion from the non-radioactive material. With regard to contamination from technically enhanced naturally occurring radioactive materials (NORM), the company's goal is to wind up with about 5% of the original volume for storage in a radioactive repository. At that level, the radioactive concentration is not so high that the material requires special handling. The remaining 95% of scale can then be recycled or treated as non-radioactive waste.

Technically enhanced NORM contamination affects the pipes, pumps, valves, and tanks used in oil and gas drilling and extraction, mostly due to scale, which is mainly a precipitation containing radioactivity. Scale, typically consisting of barium sulfate, often attracts radium, in turn creating radioactive scale.

According to Lindberg, North Sea offshore operations generate an estimated 200-500 tons/year of scale. But following treatment with Studsvik RadWaste's method, the amount of scale that would need storage could drop to 10-25 tons per year, she said. Upcoming platform decommissioning projects will only add to the amount of radioactive waste to be stored, she added.

Under the company's process, the radioactive components are separated from the non-radioactive portion. Once the liquid is removed from the material, the solids are ground down and dissolved. The material is separated into its main components, barium and radium. The resulting barium sulfate can be re-used to make concrete heavier. Lindberg said the company's goal is to find a positive use for all non-active waste. Even the radium could be re-used in a medical setting, she said, though immediate plans are focused on storing it. This procedure reduces the amount of radioactive waste requiring treatment, further reducing the cost of the process.

Studsvik RadWaste received one patent on its scale treatment process in February, and a patent is pending on another part of the process. The company, certified ISO 9001 and 14001, is looking at having a pilot plant in place in one year and a full-scale process plant in two years. Whichever country is the designated site for the plant, strict regulations are likely to be imposed by the host government. Lindberg added that Studsvik RadWaste will work wherever the radioactive waste is, rather than hazard transporting the material.

Radioactivity removal from steel

Currently, the company treats scrapped metal by melting it in an induction furnace, which homogenizes the material. Studsvik RadWaste can remove uranium from steel during the melt process, and the method can also be applied to technically enhanced NORM-contaminated material. To complete the treatment, the metal, no longer radioactive after melt decontamination, will be re-used in the steel industry.

Studsvik RadWaste's plant in Studsvik, Sweden, comprises a segmentation workshop, decontamination systems, tube blasting machine, blaster chamber, band saw, two melting furnaces, laboratory, and temporary ingot storage. The company has historically provided incineration services for low-level radioactive waste, mostly generated from the operation of nuclear power plants, nuclear fuel manufacturing plants, Swedish hospitals, and research, development, and technology institutions.

For more information, contact Björn Amcoff, Studsvik RadWaste. Tel: +46 155 22 15 08, fax: +46 155 26 31 17, email: [email protected], website: www.studsvik.se.