SWEDEN Mooring Systems: MoorLink analyzing interaction between torque, tension, and swivels

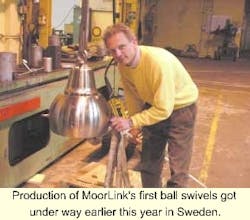

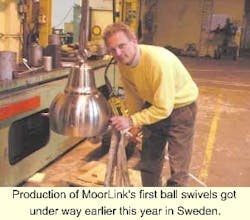

MoorLink has broadened its range of mooring components with the addition of a ball swivel for connecting chain and wire. The company already has received two orders for the new product from a Houston-based drilling rig contractor, which will use it in the mooring systems for two rigs currently undergoing deepwater upgrades. Early this year, it was close to finalizing a further order with another drilling contractor.

The ball swivel is of simple construction, consisting of three main parts - a wire-rope socket part which supports the outer housing, and an eye which is secured in the housing by a sophisticated but novel method that the company does not wish to disclose. All parts are made of high-alloy forged steel meeting Grade 4 requirements. A patent application for the design is pending, says Managing Director Björn Palmquist.

Last year, MoorLink carried out trials in conjunction with Mærsk to investigate whether the torque built up in a work wire or mooring line is satisfactorily released through the swivel when the tension is taken off the line prior to disconnection. Mærsk, which has one of the world's largest anchor-handling fleets, is one of MoorLink's leading customers, having purchased the company's anchorhandling swivels for its entire fleet.

MoorLink now plans to follow up its investigations into the interrelation between torque, tension, and different types of swivel with test-bed trials at Scana Ramnäs later this year.

Having established itself as a reliable supplier of mooring components, MoorLink is looking to widen its range of products in the light of industry needs. It is working on the development of sockets to suit the higher breaking-strength wires to be connected to the higher-grade chains now coming onto the market, such as Scana Ramnäs Grade 4 Plus chain.

"Such chains put a higher requirement on the rope, so the socket also needs to have a higher breaking strength," says Palmqvist. "We're doing in-house studies looking at different materials with the aim of getting the material strength to maintain a slim design and avoid expensive adaptors, larger sockets, and so on."

For more information contact Björn Palmqvist, MoorLink, tel: +46 31 711 18 19, fax: +46 31 708 79 00, e-mail: [email protected].