SAFETY SHOWERS: Emergency showers designed for quick response to injuries

Rig and platform operators are legally obliged to provide emergency showers wherever there is a risk of workers being exposed to hazardous sub-stances. The showers can be total body drenches, face and eye wash units or combin-ations of both. Strategically situated so that they are quickly accessible in the event of an emergency, the design of such showers has evolved to accommodate the lessons learned from the often painful experiences of industrial workers over many years.

Statoil is the latest in a long list of offshore operators to discover that there is more to an emergency shower than meets the eye, following delivery of 10 such units to a terminal in Norway by Krusman. Krusman has been based in Vasteras, Sweden since 1993. The company is thoroughly acquainted with the pain and distress problems that corrosive chemicals can cause. In addition to manufacturing showers, the company now also provides a consultancy service for platform designers, advising them of their legal obligations either personally or through the company's web site.

Need for sufficient water quantities

One of the misconceptions formed by many industries is that portable eye wash units and eye wash bottles provide an adequate remedy for workers splashed by corrosive and toxic chemicals.

"It is important to have the correct shower in the correct location" says Krusman director Daniel Krusman. "A victim with chemicals in his eyes may have only five seconds before the outer layer of the eye, the cornea, is permanently damaged," he said. "It takes hundreds of liters of cold water, starting within a few moments of an accident, to counteract the effect of a single drop of hydrochloric acid," he said. "Of course, a portable eye wash unit or eye wash bottle are insufficient - the quantity of water is far too little - and lukewarm water is far less effective. If, in addition, the water contains bacteria, the injury may be aggravated. Typically, an eye shower should have a capacity of 14 liters/min and a full drench unit 200 liters/min.

"Everyone working in the offshore industry is aware of the strict safety regulations enforced aboard platforms. Drench showers or eye-face units are no exceptions. Portable eye wash units and eye wash bottles do not belong in this demanding environment any more than they do in other industries" Krusman adds.

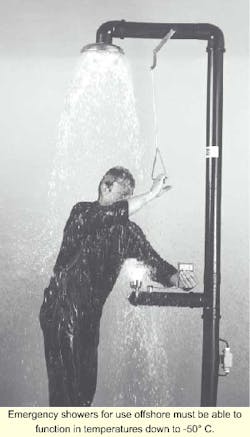

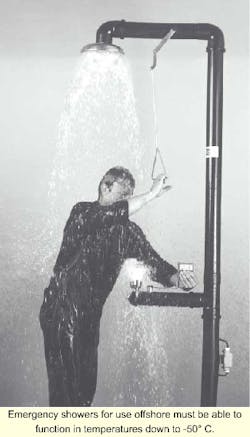

Unlike other industries, however, the offshore environment can pose special problems that his company has had to address. These are above all the cold which demands that showers and eye wash units are designed to function immediately in sub-zero temperatures. Heating elements and insulation are now built into shower units to ensure that they will function in temperatures down to -50° C. The heating element is self adjusting so that it is activated without the need for a thermostat which might malfunction.

Balanced water temperature

Heated water is not a solution to the problem of low temperatures as it is less effective against damage caused by certain chemicals. Most victims of such accidents report that they need the cooling benefit of cold water but this can present an additional problem in an offshore environment where it may be necessary to remain under the shower for up to 20 minutes. If the incident occurs in sub-zero temperatures, the victim is faced with the additional risk of hypothermia so care is needed to ensure that a correct balance between the two hazards is maintained.

Although seawater can be used to wash away chemicals, designers at Krusman advocate taking drinking water from the platform's main supply. This is typically provided at a pressure of 5 bars so a water flow control mechanism is built into the shower. This is particularly important in the case of eye wash units which reduce the pressure to just 0.5 bar to ensure an adequate but tolerable water flow that does not harm the user. A further refinement includes a device that removes air bubbles from the water. This is manufactured under Krusman's own patent and ensures that the victim is not endangered by the damage that water bubbles can cause to the eyes and that the emergency shower does not aggravate the problem it was installed to overcome.

For more information contact Daniel Krusman, Krusman Nordduschar. Tel: +46 21 14 92 00, Fax: +46 21 14 92 50 Email: [email protected]