DRILLING & PRODUCTION

John Waggoner • Houston

Jim Redden • Contributing Editor

Unmanned rig design moves forward

The latest developments in the design of an unmanned and fully automated seabed drilling rig for ultra deepwater and arctic conditions generated interest at the DOT International Asia-Pacific conference in Perth, Australia.

Seabed Rig AS presented the first phase of its design for a rig that sits on the seafloor and eliminates the need for heave compensation, dynamic positioning, drilling risers, and manned personnel. It will be connected to a surface vessel by flexible umbilical for power, communication, cement, and mud flow.

The seabed rig will have many of the same components of a conventional drilling rig, but adds sophisticated innovations such as robots, a tool magazine, and systems for circulating and cleaning water.

Phase 1 was finished in August and included:

- Contingency handling

- Control system topology

- Detailed concept evaluations of the top drive, lift, pipe handler, robot, and slips function

- Design and production of the encapsulated iron rough neck

- First version of the visualization software, with interface for the roughneck.

Phase 2 kicked off in September 2008 and is scheduled to be completed by August 2010. It includes:

- Production of the main machines: Top drive, lift, pipe handler, robot, slips function, and tool magazine

- Assembly of the main machines, including roughneck and a pipe magazine

- The building of a water tank with a diameter of 17 m (56 ft) and a depth of 11 m (36 ft), with a 25 m (82 ft) deep well below the tank

- Full scale testing of the main machines submerged in water, with tripping simulated drilling, etc. into the well below the tank.

Phase 3 will include the building and testing of a complete Seabed Rig on the seabed, and the drilling of a 3,000-m (9,842-ft) vertical exploration well.

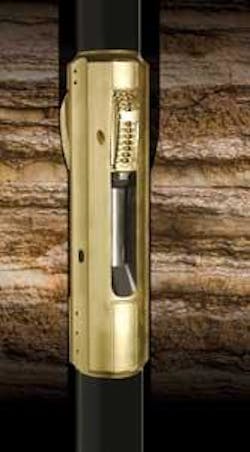

Expandable reamer cuts vibration woes

A sturdy new expandable reamer can achieve a drastic reduction in wellbore vibration when used in the BHA to ream the borehole while drilling, says Hughes Christensen.

The company’sGaugePro XPRtool was designed to solve many of the chronic reamer problems faced by the industry such as complexity, activation, downhole failures, and vibration/stability dysfunction, the company says.

“Our design team was determined to engineer a tool that would remain closed until triggered, open on command, ream an in-gauge hole, and then close and come out of the hole properly,” says Steve Radford, GaugePro XPR project manager.

The expandable reamer has a balanced cutter profile that was tested and found to be equal to or to exceed the stability of a typical, same-diameter drill bit. The stabilization pads in the body of the tool immediately below the cutting structure further enhance this stability.

“These replaceable hard-faced pads eliminate the need to weld directly onto the tool body, preventing potential heat-affected-zone crack propagation found on other underreamers,” Radford says.

The tool is unique in that it provides synchronization of the pilot bit and reamer, which helps to control vibration. GaugePro XPR also has roughly half the moving parts and seals as other designs, Radford says.

It underwent reaming and drilling tests through 27,500 ft (8,382 m) of mixed formations in 20 wells at the Baker Hughes Experimental Test Area (BETA) near Tulsa, Oklahoma. Other tests for extreme torque, high axial load, stability, high temperature, erosion, and fatigue confirmed the ruggedness and reliability of the design.

A paper on the topic presented at SPE showed that bit and reamer whirl and stick-slip vibration were isolated and reduced by 40-80% with increased WOB and ROP compared with industry-standard methods.

Deepwater DPR comes of age in Brazil

A second-generation drill pipe riser (DPR) has emerged from deployment in deepwater Brazil, where corrosive gas at high pressure poses a challenge.

The new version is based on high-performance pipe, combining a double shoulder connection with a metal-to-metal seal, among other refinements.

Thomas Peter of Vallourec Mannesmann Oil & Gas France discussed the development of the new system in a presentation at the Deep Offshore Technology Conference and Exhibition Asia/Pacific in Perth, Australia.

The original DPR system was installed in Roncador field in 1,800 m (5,905 ft) in 1999. It was designed to provide a mobile, early production riser for use on a floater performing extended flow tests of producing wells that were new or recompleted.

In 2006, development of high-pressure gas production in the Espirito Santo basin required improvements in the system in order to handle corrosive gas at 10,000 psi. Here are the latest innovations:

- Metal-to-metal seal relocated close to the internal shoulder

- New thread profile with a triangular thread having a reduced angle on the loading flank

- Larger pitch diameter

- Stress relief groove added to the box.

Testing is under way at Golfinho field in 1,608 m (5,276 ft) of water and at 6,000 psi from a semisubmersible.

Caledyne MTM seal patented for Europe

Caledyne has been granted a European patent for its retrievable metal-to-metal (MTM) downhole seal system that overcomes the limitations of elastomers by encasing flexible material inside a metal shell.

The structure forms a complete metal barrier in the well, and when fully energized, shelters it from chemical attrition downhole.

According to the seal’s inventors, the technology responds to environmental and financial concerns about the longevity and integrity of elastomers.

“Mature or abandoned wells are susceptible to leaks and increases in pressure, making a reliable downhole seal even more crucial,” says David Martin, technology director of Caledyne and one of the seal’s inventors.

The system behaves much like a standard rubber or elastomeric seal, while remaining resistant to high hydrogen sulphide (H2S) and carbon dioxide (CO2) concentrations found in the harshest downhole environments.

Mexico policy still leaves IOCs out in cold

While Mexico’s long-anticipated “energy reform” still leaves international operators wanting, preliminary indications suggest global service companies could find a more accommodating client in Pemex.

With production declining steadily, particularly from the giant Cantarell field in the Gulf of Mexico, lawmakers passed the controversial measure aimed at reversing the precipitous drop that reached a 13-year low in September. Early thinking was that the so-called reform would encourage international companies to bring their expertise to Mexico’s relatively virgin deepwater sector, which many have said holds the best potential for reversing the production decline.

However, now that the dust has settled in the Mexican legislature, observers say not to expect the Shells, BPs, Exxons, Chevrons and other international oil companies to begin acquiring offshore leases anytime soon. The new law explicitly continues the perpetual ban on international companies owning any portion of the nation’s oil and gas resources, which always has been a source of nationalistic pride for Mexicans. On the other hand, the policy shift does depoliticize Pemex with oil and gas professionals replacing government appointees on the operator’s board of directors, which purportedly bodes well for service companies.

Observers say the policy shift gives Pemex more flexibility in contracting with international service companies, going so far as to allow the operator for the first time to pay performance bonuses. In a legal interpretation, one of Mexico’s most prestigious law firms, Lopez Velarde, Heftye, y Soria, says the new policy increases regulatory oversight and moves the nation closer to the models established by Brazil and Norway, never mind that those two countries allow international oil companies to hold leases and to drill within their borders.

“Mexico has never had an upstream authority, and Pemex, as the single E&P operator in Mexico, had very limited E&P regulation and supervision. No long- or mid-term energy policy or planning existed in Mexico and the decision on projects to be undertaken was mostly done on the basis of short-term revenues by the Ministry of Finance. With a resulting decrease in reserves, and the consequent current steep declines in the major production fields, this structural reform will change the shape of the oil and gas industry, which new arquitectural framework would facilitate the introduction of further and deeper reforms in the industry,” according to the firm.

The policy also creates a new National Hydrocarbons Commission, which follows a model somewhat similar to that of Brazil and Norway, the attorneys say, adding the new agency “will be entrusted with the obligation to regulate and supervise the exploration and production of all domestic hydrocarbons, approve all exploration and production projects from the technical perspective, including a review and approval of all operating licenses to Pemex from the technical point of view.”

Further, the Secretary of Energy is given much broader authority to regulate Pemex and the energy industry. The energy chief also will have a prominent role on a new National Energy Council that will be in charge of preparing and implementing the 15-year National Energy Plan.

One of the more unambiguous components of the new law is the historic overhaul of Pemex. “As a public instrumentality of the federal government, Pemex has had very limited flexibility and limited incentives to behave as an international oil company. One of the major changes in this reform is the adoption of a series of corporate governance rules and principles that will try to replicate as much as possible a structure of a ‘public company,’ aimed at enhancing economic value in underlying contracts to be issued, ” according to Lopez Velarde, Heftye, y Soria.

“We will expect that Pemex contract rules will try to adjust to industry standards, and make such new type of contracts attractive enough in order to bring the necessary investment from private players. There is an urgent need to increase reserves and at least maintain the current production levels (2.8 MMb/d) since Pemex’s largest field (Cantarell) is declining sharply,” the firm adds.

BHI, SLB bet on future with new centers

Today’s oil and gas prices may not be anything to write home about, but two of the world’s largest service companies are banking that the future will be an altogether different story.

Baker Hughes and Schlumberger backed up their optimism in late 2008 with the opening of multi-million-dollar research and testing centers in Houston and Aberdeen, respectively. The reported $42-million Baker Hughes Center for Technology Innovation will concentrate on developing technologies for HP/HT and other harsh environments. Schlumberger, meanwhile, expressed its confidence in the future of the deepwater with its Well Control Center of Excellence in Aberdeen.

In what it describes as a potential “magnet for technical talent,” the Baker Hughes center includes research labs and test cells that can simulate HP/HT environments. Schlumberger says its new subsea well control facility addresses the growing deepwater market, particularly in the North Sea, Africa, and the Mediterranean regions.

Oil recovery nets award

The M-I SWACO Production Technology group won the prestigious International Platinum Award for technology it developed to safely extract oil trapped in the attic space of the subsea storage cells in the UK North Sea Dunlin field.

A world’s first and the result of three years of intensive work, the Shell Dunlin Attic Oil Recovery project was unprecedented in its scale and complexity in the North Sea. It involved in situ gas generation within the cell structure of the North Sea installation. The aim of the project was to safely free the four cell groups of the remaining 1.5 MMbbl of liquids, including 250,000 bbl of oil.

The patented technology displaces the crude oil layer to the level of the export pipe for recovery. Following complete oil recovery, the gas cap is absorbed using a scavenging system to fill the cells with seawater. The 76 supporting cells located on the seabed 495 ft (151 m) beneath the Dunlin platform are now full of seawater and free of oil.