Fit-for-purpose engineering streamlines subsea developments

Kerr-McGee achieves production cheaper, faster

Jaime Kammerzell

Gulf of Mexico Editor

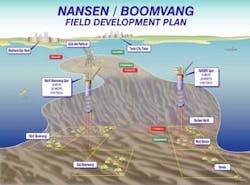

Kerr-McGee Corp. pioneered the use of spar technology in deepwater field developments in 1997 at its Neptune field in the Gulf of Mexico in 1,930 ft of water. Kerr-McGee was also the first to use truss spar technology at its Nansen field in the East Breaks area in 3,675 ft of water. In January 2002, the company first tied back subsea wells to Nansen, and in 2003 tied in a satellite field, Navajo, to the same field. The company's innovative production technology and core-area approach for cost-effective developments has led to cost savings and achieving first production faster.

Kerr-McGee's fundamental concept in the GoM is the hub and spoke.

"Our stated philosophy is to build a floating structure that can be used as a hub for other developments. We pick up enough leases in an area, put in a floating structure, then pick up additional leases in the area that have potential for subsea tiebacks," Don Vardeman, director facilities engineering for Kerr-McGee, says.

As Kerr-McGee installs each spar, the company has one or two subsea tiebacks planned, but continues to seek other hydrocarbons in the area to tie back. The company can develop future satellite field discoveries more quickly and at a lower cost with subsea wells tied back to the hub spars.

Fit-for-purpose engineering

Kerr-McGee has tied back 18 deepwater wells in the past five years to five different hubs. The company has aligned itself with FMC and Kværner Oilfield Products to develop and hone a package that's interchangeable across the fields.

"One of the things we try to do once we discover hydrocarbons is get a tree, control system, umbilical, and flowline installed quickly and get the well on production as fast as we can," Vardeman says.

By working with FMC and KOP on standardizing products, Kerr-McGee has the two longest-lead delivery items already coming through supply chain before they know if hydrocarbons are present. If the company does not find hydrocarbons, they can put the equipment on the next well, avoiding a backlog of hardware they can't use.

"This system allows us flexibility in how we are able to pull our equipment together when we have a discovery," Vardeman says.

Kerr-McGee has a standard tree and controls solution for deepwater wells. "It is an FMC 10K rated tree with a KOP multiplexed electro-hydraulic controls package," Tim Dean, subsea projects engineer, Kerr-McGee, says.

Kerr-McGee also adds wells to existing fields that already have KOP systems in place. "Having similar hardware across all the fields means that we don't get in a bind moving equipment from one location to another," Dean explains. "The equipment for the well we install today is similar to the one we installed two years ago."

Standardizing equipment requires a careful balance between regulatory and operational requirements.

In 1999, Kerr-McGee established functional specifications for subsea trees and controls. The company defined a standard to meet most of its anticipated needs. "At times, we could use less equipment than we have on the trees, but keeping to a standard is much more economical than trying to custom build them," Dean says. "The extra flexibility is worth more than the extra cost."

The day savings on the drilling rate alone has saved the company significant cost. Kerr-McGee has completed all 18 deepwater wells with the same completion rig, Diamond Offshore's semisubmersible Ocean Star.

null

Surprisingly, the functional specs developed in 1999, before these 18 deepwater wells, are significantly the same. "We've tweaked details on trees, but the basic functionality is the same," Dean says.

FMC produced seven first-generation trees, then changed the details on the tubing hanger, made the tree lighter and easier to handle, made the footprint more compact, and changed actuators from rotary override to a linear override. The company built 12 second-generation trees to this design. Another batch of four third-generation trees is currently underway at FMC, incorporating minor changes.

"We've changed our electrical connector supplier, changed our needle valve supplier, and changed our smart well control line to actuated valves from ROV-operated valves, but the tree will look pretty much the same," Dean says.

Project team

When a completions group has standardized equipment, they get to know it, and go through dramatic learning curve gains.

"By not throwing them curves with hardware that they have to relearn each time, it helps them focus on the rest of the job, and feeds on itself," Dean says. "Just as standardized equipment helps us manage with continuity and hardware, it also helps to have continuity with people doing the work."

Kerr-McGee sees the value in capturing "learnings" and rolling those forward into the next job. Many companies look at each project in isolation and bid out engineering for each project in a stand-alone effort. It is difficult to "staff up" to meet peak manpower requirements. Prior to drilling and completing its 18 subsea wells, Kerr-McGee looked at its upcoming work – a series of small jobs continuing with one-, two-, or three-well tiebacks.

"We built a core group to support engineering and design at JP Kenny, and now we can level out some of the peaks across the various jobs and get continuity," Dean says.

Kerr-McGee does not have to train new people about how the company works, its procedures, or its hardware. JP Kenny's team brings its knowledge from previous work.

"Kenny is a good extension to our project team," Dean says. "We have a core group of three people to manage subsea projects. We stay closely coordinated on what we are doing with the trees and controls. We are all using same hardware, and we are drawing from common resource at JP Kenny, who also knows our hardware."

Future developments

Kerr-McGee's next big hub in the GoM is the Constitution field in Green Canyon block 768 in 5,050 ft of water. It is the company's sixth deepwater hub and will be developed with a truss spar. Kerr-McGee will tie back the Ticonderoga discovery well, 5 mi away, when Constitution comes on production in mid 2006.

The Merganser natural gas discovery in the Atwater Valley area in 8,000 ft of water has potential for another deepwater hub. Kerr-McGee is working with other operators in the area to determine the optimum development scenario. Kerr-McGee discovered natural gas in the nearby Vortex prospect in late 2002, which will be included in this deepwater development.