Long-length flowline tailored to high-temperature project

NKT Flexibles recently supplied a record length of polyvinylidene fluoride (PVDF) flowline for a high temperature project in the Dutch North Sea. Nederlandse Aar-dolie Maatschappij awarded the contract last October with Stolt Offshore as main con-tractor.

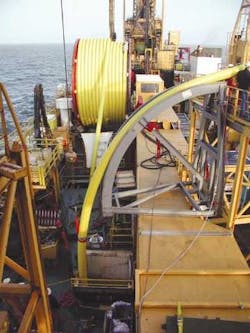

The work scope included design, engineering, manufacture, and supply of an 8,270-m long, 10-in inside diameter flowline with a design pressure of 120 bar, to be installed around 70 km northwest of Den Helder. It will be used for gas production from the K15 platform in 27-m water depth.

null

This particular flexible pipe is molded to the requirements of this shallow-water project. It is a Flex2 type (an NKT patent), designed with armor wires cross-wound at an angle of 55° to balance the pipe's radial and axial loads.

According to NKT, another feature is that this pipe is not susceptible to upheaval buckling failure due to internal pressure. The company says this is the longest continuous length of 10-in. PVDF pipe ever produced.

The material used for the pipe's inner leak-proof polymer layer is designed to meet the requirements on K15 of 100° C in the pipe bore. The unplasticized PVDF grade is a thermally, mechanically, and dimensionally stable material.

To validate the pipe's structural integrity, a sample was subjected to a burst test at NKT's test facility in Kalundborg, Denmark. The test was conducted in accordance with the requirements of API 17J and API Recommended Practice 17B. The burst test result was 407 bar, which was within 1% of the predicted value – based on the mean yield stress of the combined pressure/tensile armor – and more than three times the design pressure.

NAM appointed Stoomwezen (STW) Holland as its third-party verification body; Lloyds, Holland, audited the project this January on NAM's behalf. Load-out of the pipe onto Stolt's installation vessel Falcon was performed in a 20-hr operation. NKT's quayside facility was also used to mobilize rigid pipe joints and subsea equipment. The flowline was successfully in-stalled on the field in May.