DRILLING & PRODUCTION

Frank Hartley • Houston

null

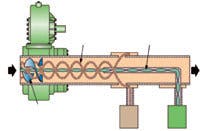

Turbo oil/water separator

According to a Fort Lauderdale, Fla., company, Enviro Voraxial Technology Inc., it has developed a continuous-flow turbo machine that produces a high centrifugal force to separate liquid mixtures.

From its origin as an aerospace manufacturer, the company says it has invested over $10 million and a decade of research to develop a technology that is targeted to impact the global market for separation and filtration. The turbo separator system simultaneously separates liquid/liquid, liquid/solid, or liquid/liquid/solid flow streams at very high flow rates.

The separator is fitted with a patented, low-shear, non-clogging impeller designed to create a cyclonic flow. By this action, the company says, the heavier materials, i.e. solids, are forced to the outside of the vortex while lighter materials such as oil are drawn to form a central core of the vortex. A specially designed manifold at the exit of the separation chamber is utilized to collect the separated streams.

The separator can process high flow rates, is compact, and has a very small footprint.

There has been, and will continue to be, an increasing need for separation capacity of produced water on offshore production platforms, where in many cases there is no room for additional equipment.

The company says it is working with oil companies interested in solving produced water issues, either to recapture the oil to include in their sales line or to increase the purity of the water stream for environmental reason. When the amount of produced water increases with the age of the well, the ability to retrofit the separator within an existing platform or production facility is a definite advantage. The company says it is working with operators that have produced water issues ranging from 25 gpm to over 9,000 gpm. In either extreme, the separator may deliver an economic and environmental benefit.

In a recent project at an oil production facility of a major oil company, a return on investment of less than six months was projected, based on the recovery of oil prior to re-injecting produced water. The operator reported that the separator installation could also be justified by its simultaneous ability to remove sand that was causing unacceptable downtime due to pump failures. Additionally, cleansing the water prior to re-injection increases the life of the well.

According to the company, the applications are driven by economic incentives and environmental mandates faced by operators, and many are in various stages of discussion, evaluation, or order generation.

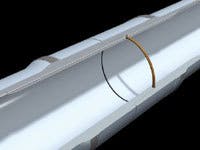

Real-time telemetry

Grant Prideco has announced the commercial launch of its IntelliServ Network, which the company describes as the industry’s first reliable high-speed, real-time drillstring telemetry system.

The technology will transform the drillstring into an advanced information tool that allows for instantaneous bi-directional communication between downhole tools and engineers at the surface, the company says.

Mike Reeves, VP and general manager of the IntelliServ division, describes the new telemetry system as a “marked improvement” over current mud pulse telemetry technology. Data transfer occurs at speeds up to 57,000 bits per second, more than 10,000 times faster than with mud pulse.

Plans are in place to increase this rate to 1 million bps by the end of 2006. That speed will allow for the transmission of images to the surface in real-time and will provide for seismic measurements while drilling.

IntelliServ allows for transmission of commands to a downhole tool from the surface, something that is a challenge for current mud pulse technology. Real-time data transmission in the presence of any fluid medium is possible, and the pipe does not need to be full to successfully transmit data, the company says. A large number of discrete tools, from standard direction and inclination sensors to rotary steerable and fishing tools, can be networked into the system.

There are no depth limitations to the technology, according to Grant Prideco, allowing for longer step-outs on extended reach drilling projects. Reeves comments that “the first niche application for the technology is long extended-reach lateral drilling environments.” The system contains boosters that are placed in the line every 1,500 ft to allow for continuous data transmission in deep drilling environments.•