Mission-critical video finds increased offshore industry application

Actually seeing something - “eyeballing” it - usually proves that it truly exists. Nothing verbal or written can match that. A picture, as they say, is worth a thousand words. But a real-time video picture expands its worth in words almost exponentially.

That’s why mission-critical digital video applications are so important today for observing and monitoring operations at remote locations.

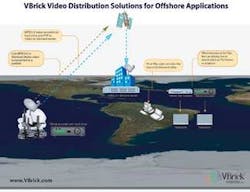

VBrick Systems Inc. is a leader in enterprise-wide video applications for Internet Protocol (IP)-based networks. VBrick is deploying industrial-strength “plug-and-play” appliances that enable companies with offshore operations to add remote process monitoring applications seamlessly to their existing IP networks, regardless of site location.

Shell unit deploys IP video system

For example, the Wallingford, Conn.-based company recently provided Shell E&P Co. (SEPCo) - Shell’s US drilling and production business unit - with a real-time video system to help create a long-distance, collaborative effort to lower the cost of drilling offshore wells. With the VBrick system, Shell is bringing visual drilling information to experts on shore in lieu of sending the experts out to sea to observe operations in person.

Shell traditionally had deployed experts to offshore locations to advise drilling personnel and to sidestep potentially expensive operational challenges. However, such deployments were time-consuming, costly, and limited experts’ focus to single drilling locations at a time.

So, Shell selected VBrick for remote monitoring capabilities to its Real-Time Operations Center (RTOC) back on land. VBrick digital video appliances connect to video cameras for both fixed and “roving” video camera capabilities on drilling rigs and development drilling platforms. (Each VBrick appliance is approximately the size of a dictionary, making digital video capabilities extremely portable.)

Engineers stationed at the RTOC use remote camera pan/tilt/zoom controls to “zero in” on potential rig problem areas - such as a drilling component that is performing poorly - and diagnose repairs remotely.

VBrick receives analog video from each camera, then digitizes and compresses (encodes) the video streams for broadcast across the organization’s existing IP network. For Shell’s system, each remote VBrick appliance transmits secure, high-quality video across the company’s satellite communications network, whose video server redistributes it to multiple locations simultaneously for live viewing, or records it for later viewing on demand. Shell’s choice of MPEG-4 video compression, though high in quality, requires only 64 (kb/sec) of bandwidth capacity. Companies that elect to increase bandwidth for video streaming can see a resulting increase in quality. In addition to MPEG-4, VBrick supports the most widely deployed digital video formats, with encoder/decoder appliances that support MPEG-2 and 4, as well as Windows Media standards for high and low-bandwidth network connections.

Ruggedized equipment withstands harsh elements

Andy Howard, the company’s product marketing manager, said their ruggedness, easy management, reliability under harsh environmental conditions and quick manipulation characteristics were factors in Shell’s choice of VBrick systems for the SEPCo offshore operation. The results have been extremely successful, he added.

“We enable oil and gas companies to increase their production yields, reduce costs and minimize risk by monitoring remote facilities with IP video,” said Howard. In addition to remote monitoring, many organizations use VBrick for two-way “virtual presence” audio and video communications between a remote site and central operations. Such real-time transmission capabilities, for instance, make it possible for specialists on land to review specific equipment procedures with on-site technicians just prior to implementing them, he said. “The ‘always on’ feature of VBrick eliminates the frustration of the dropped calls associated with traditional videoconferencing equipment.”

Energy companies are also adding digital video appliances to remotely operated vehicles (ROVs) to monitor installation/operation of seafloor drilling equipment. Many organizations also use VBrick to stream live and archived training programs to their offshore facilities. VBrick also enables organizations to access content anytime via on-demand capabilities.

“Additionally, matching IP networking with VBrick appliances equipped with wireless cards permits two-way teleconferencing at remote on shore drilling locations,” said Howard. Similar cards for cellular-based conferencing can be installed as well, he said.

Meanwhile, VBrick continues to market its mission-critical video appliances and systems throughout the offshore petroleum industry, as well to other corporate applications, such as executive broadcasting, training, and even digital signage. Additionally, VBrick markets its products for both government and educational opportunities.

For more information about VBrick Systems mission-critical video equipment and systems, contact the company at 203-265-0044; Fax: 203-265-6750. The company web site iswww.vbrick.com.