Phoenix Hardsuit ADS can minimize downtime, cost

As oil and gas companies continue to utilize cost cutting measures as a result of the prolonged downturn in the industry, Phoenix International Holdings, Inc. has remained committed to offering cost-effective underwater services. To that end, the company has utilized its Hardsuit atmospheric diving system (ADS) for more than 14 years to provide their clients with reduced overall project time, costs, and risk for their subsea projects.

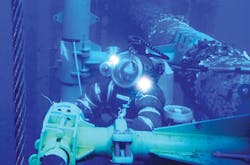

The Hardsuits have long been utilized for installations, inspections, maintenance, repairs, and decommissionings. As the progression of methods and procedures continues to change and advance, the systems are also being used for heavy installation work, including risers, large connectors, pull tubes, steel catenary riser porches, guide frames, and subsea trees.

Since 2003, Phoenix has owned and operated two Hardsuit systems, each comprised of two suits, which have worked on more than 100 projects in water depths ranging from 92 to 1,150 ft (28 to 350 m), in locations throughout the Gulf of Mexico and around the world, including West Africa and the Mediterranean. The system’s capability and versatility was recently put to the test when Phoenix took on a project in West Africa on a platform and loading buoy that required a full spectrum of the company’s services, including engineering, project management, and air and mixed gas diving.

For their part of the project, Phoenix ADS pilots were assigned with the installation of two risers (each a single piece measuring 267 ft- (82 m-) long and made of highly specialized steel) while decommissioning the two old ones; installing new clamps; installing anodes on sleds; disconnecting pipelines; and decommissioning closing spools and installing new ones. To perform the work, 709 hours were logged in 137 dives, operating in depths down to 300 ft (91 m); oftentimes, multiple depth changes per dive were required to perform the task at hand.

For traditional divers to perform multiple depth changes outside of their excursion limits, decompression time and surface intervals are required. Because the ADS is one atmosphere, the pressure remains constant and the diver/pilot is able to efficiently perform the work with no decompression time, thereby decreasing costly downtime.

In addition to offering cost and time savings, the Hardsuit is also one of the safest means of performing underwater work where a manned presence is preferred.