CP survey confirms integrity of Jubilee field subsea equipment

Over 430 anodes examined to determine remnant life

Fred Tandoh

Tullow Ghana, Ltd.

Brian Gibbs

Deepwater Corrosion Services, Inc.

Andrew Mallon

Codex Integrity Ltd.

To help Tullow Ghana Ltd. (Tullow Oil) meet its commitment to safe and reliable operations, Deepwater Corrosion Services, Inc. was selected to prepare and execute a cathodic protection (CP) assessment for the deepwater Jubilee field, offshore Ghana.

A full-field survey was commissioned to provide essential data on anode performance (potential levels and continuity), anode wastage (sizing), and the protection of flowlines (pipelines) from their associated structures. Most of the subsea infrastructure was installed in 2010.

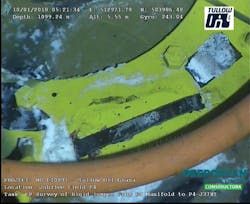

CP measurements are taken on a marginally wasted anode.

As a result of routine subsea IMR activities, there was one concern regarding the CP system: depletion of the rigid jumper vertical connector system (VCS) anodes. The survey scope included analysis of the root cause of this anode depletion and an assessment of anode remnant life for all structures.

Working closely with Codex Integrity Ltd., who are Tullow’s subsea asset integrity providers for the Jubilee field, Deepwater managed a focused CP survey on the subsea production, injection, and export systems. The CP systems were found to be working well and providing good levels of protection to the equipment. Over 430 anodes were cleaned to allow actual depletion to be observed and estimated, and this confirmed that their condition (remnant life) was projected to be sufficient for the remainder of the 25-year service life. The VCS hubs were also proven to remain protected by adjacent anodes.

For the VCS anodes, the conclusion reached was that poor detailing of the CP design led to excessive depletion of the anodes protecting the rigid jumper upper surfaces. The small and slender anodes on the connectors depleted faster than the larger anodes typically installed in the field. CP measurements confirmed the excessive wastage was not a cause for concern at the time as sufficient protection was afforded by the anodes located on the lower VCS hub connections.

It is important that anode design and selection is adequately reviewed in the equipment design phase.

Jubilee field

The Jubilee field is located 60 km offshore Ghana’s western region, in water depths ranging from 875 m to 1,515 m. The field, developed in 2010, consists of east and west production systems, with five drill centers and 14 production wells tied back to the FPSO Kwame Nkrumah. Production is boosted by gas injection on the eastern zone and water injection, installed in 2012, in both the east and west zones. The produced oil is stored in the FPSO and the gas (except that used for injection and power generation) is exported via a subsea pipeline to the onshore receiving facility operated by Ghana Gas. All subsea equipment is protected using aluminum sacrificial anodes. In total, there are approximately 130 km of infield flowlines. The flowlines and rigid jumpers do not have anodes and rely on the anodes on the pipeline end termination (PLET) structures.

Since first oil, several routine subsea surveys have been undertaken, including CP monitoring. The previous full-field CP survey in 2015 had indicated that the field performance was adequate, but Tullow considered it prudent to undertake a further assessment of performance, particularly for the VCS anodes (due to a lack of comparable operating data in this region). The previous survey had also identified that, although there was good anode polarization across all structures, the anodes appeared to have significant corrosion-product; it was then deemed necessary to monitor them from a full-field life perspective.

As a proactive and responsible operator, Tullow wanted to understand the cause and impact, if any, of the excessively wasted anodes on the jumper vertical connectors. Their assurance program requires that all Jubilee field CP systems were performing adequately and that the existing anodes would survive the full 25-year design life.

Above: Typical 100% wasted anode: only the anode core remains. Below: Typical anode that has been marginally wasted.

The detailed CP survey was designed to address these concerns. Separate CP design and specifications reviews had been recently completed, and the composition of retrieved anodes from decommissioned wells had also been analyzed. Apart from anode sizing and spacing, the only other potential contributing factor was lack of continuity between the upper and lower VCS elements.

Survey planning

The comprehensive survey work program was jointly developed by Deepwater, with their expertise in CP technology, and Codex Integrity, with their experience in the design, integrity management, and inspection history with the Jubilee field. Deepwater had responsibility for determining the most appropriate survey techniques, developing survey procedures, and identifying the extent of examination. Codex led development of the risk-based prioritization of work, as well as providing critical input and historical knowledge to Deepwater’s development of the survey procedures. DeepOcean Ghana provided the infield marine vessel (OSS Dina Star), the ROV spread, and the vessel survey crew. Deepwater provided the CP Specialists and onshore technical support in Houston.

Using CP probes, the procedures necessitated contact measurements on equipment and field gradient measurements on flowlines. To address Tullow’s primary concerns, it was specified that, in addition to taking CP measurements, selected anodes would be cleaned to bare metal to allow their remnant size to be correctly estimated. This is the only way to truly estimate the remaining life of the anode; periodic cleaning has no significant impact on anode performance, although there do remain some legacy views within the oil industry that permanent anode damage may result.

The risk-based prioritization inherent in Tullow’s integrity management approach considered several factors but prioritized the consequence of component failure to safety, the environment, the business, and historical survey findings of equipment condition. The oil production systems were assessed to include the highest priority elements, followed by the gas export and injection systems. The duplex design of the production systems, with dual flowlines (one operating, one standby) allowed further scheduling refinement, as did the functionality of the components. All items that directly affect primary containment control were ranked to a higher criticality.

The initial focus of the January 2018 offshore campaign, as per the risk-based prioritization, were the west and east production systems. As this was purely a CP assessment exercise, the survey was primarily confined to CP measurements, anode condition, and visual inspection of areas of corrosion related anomalies, if any. The exception was that if a new significant anomaly was found that was not CP related, it would be fully inspected and reported. The historical visual survey reports were made available to the offshore crew for ease of reference.

CP and field gradient measurements were fed directly into Deepwater’s proprietary data logging system. Codex and Tullow agreed that once an adequate dataset was established, representative sampling was acceptable unless directed otherwise by the onboard CP specialists, or the Deepwater onshore team. This approach eliminated the need for inspection of every anode on each main structure elevation.

Data and assessment

Almost 900 CP measurements were taken across the subsea systems inspected, and over 430 anodes were cleaned and inspected using the on-board ROV water jetting system. CP field gradient measurements were taken on the flowlines and seabed sections of the flexible risers. The upper boundary of the riser surveys was at the cathodically protected cable tether systems.

All CP readings were more negative than -850mV, and the great majority (98%) were more negative than -950mV, indicating very good, consistent cathodic protection. Deepwater recommends -850mV to be the limit of good protection, even though this is 50mV beyond the industry accepted limit of -800mV. This limit allows time to plan and install retrofit CP before the CP decreases to the accepted protection limit.

All inspected anodes were graded on a 5-tier scale, with ‘Grade A’ being anodes that were not active, and ‘Grade E’ being anodes that were fully consumed; i.e. leaving only bare steel cores. Using this 5-tier scale, the distribution of anode depletion, except for those on the VCS connectors, was as shown in the “Anode wastage distribution” table.

This qualitative scale, with concise descriptions of each classification (for use in the field by the CP specialists), is preferable to the common practice of quoting estimated percentage depletion. Even if the original anode size is known at the time of inspection, without physical measurements, it is impossible to quantify the extent of depletion.

To determine where the anode depletion grades should be, a general estimation was made. The equipment, except for some extension of the water injection infrastructure, was installed in 2010, making it almost eight years old at the time of the survey (about one-third of the 25-year design life). On the qualitative A-E scale, the anodes should all be grades B or, at worst C, if they are likely to survive the full design life. On this scale, the great majority of the anodes were minimally wasted, aligning with the expectation for them to survive the 25-year design life.

All anodes inspected on the rigid jumper vertical connectors (upper surfaces only) were extensively (grade D) or fully wasted (grade E), which was expected from previous inspection reports. It was concluded the reason these were so greatly wasted was because the original anode cross section was much smaller than the bulk of the anodes on the adjacent equipment.

This does not present a problem in the short term, and, potentially, there may be no overall detrimental effect in the long term. It is obvious from the CP readings on the vertical connectors that they remain protected, so they are clearly receiving CP current from other anodes – likely the ones installed in the lower VCS hub structure.

One issue remaining, while minor, is that the spent anode cores increase the bare steel area needing protection. There is usually some conservatism in CP design that should accommodate this additional bare steel. Surveys in future years will determine if there is any significant impact on the wastage of the anodes on the vertical connectors.

The infield flowlines do not have their own anodes and rely on the PLETs they are connected to for protection. Given these are mainly short lengths of piping, with good quality fusion-bonded epoxy coatings (production flowlines also have an overlay of glass syntactic polyurethane insulation providing physical protection of the FBE), this approach to CP is reasonable.

For the flowlines, it was deemed technically unacceptable and impractical to attempt CP stabs though the coatings. Therefore, CP field gradient measurements taken on some of the flowlines confirmed that there was adequate capacity in the PLET anodes to provide protection. However, from a logistical and cost-of-survey perspective, field gradient measurements can be very inefficient for this situation. Taking field gradient measurement readings is a slow and meticulous process. It requires the ROV fly at a constant height above the flowline, typically at speeds of 0.85 km/h. The 130 km of flowlines in the Jubilee field would take over 150 hours survey time to complete with this method.

For future surveys, a more simple and effective approach was proposed; it involves establishing CP test stations at the mid-length of each flowline. Each test station would consist of an electro-mechanical clamp with a discrete contact tip to make the electrical connection to the pipe outer wall. The contact tip would be electrically connected to a small bare steel plate and positioned for the ROV to take a stab reading. If the bare steel plate is at a protected potential, then all other points on the flowline must be protected. The prefabricated test stations are a relatively non-complex installation and the payback period may be covered within a single flowline field survey.

The Jubilee subsea structures, as with the flowlines, have very good quality coatings. This presented a challenge for taking CP readings as the coating was difficult to penetrate with the CP probe contact tip. In the longer term, it does not make sense to damage good quality coatings to take CP readings, only to prove that the steel is cathodically protected. CP test stations, like those described above for the flowlines, would allow reliable and repeatable readings to be taken quickly at predetermined critical points.

Conclusion

The value of this survey to Tullow is that they now have a quantitative set of data that demonstrates that, from a subsea corrosion protection perspective, they are meeting their commitment to operating their assets with high level of integrity management. Doing so will ensure safe, reliable, and profitable operations, as well as providing a sound baseline for measuring future performance.