BHGE launches advanced fluid analysis and sampling while drilling service

Baker Hughes, a GE company (BHGE) has introduced its FASTrak Prism fluid analysis and sampling while drilling service. The service uses advanced sensors and proven technology to collect and deliver reliable, industry-leading volumes of high-quality fluid samples and comprehensive, real-time reservoir characterization. These samples provide valuable insight into the reservoir to help operators improve efficiencies and make more informed decisions around their overall well completion and production strategy.

“We developed the FASTrak Prism service to address the industry’s need for a better, more accurate understanding of the subsurface while drilling in complex environments,” said Herman Nieuwoudt, Logging While Drilling Product Line Director. “The growing need for cost-efficient reservoir fluid characterization solutions for challenging, highly-deviated and extended-reach wells underscores the need to collect accurate, real-time information so operators can evaluate their reserves and make better asset development decisions, as quickly and efficiently as possible.”

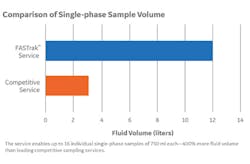

Unlike conventional services that can require additional post-drilling runs to collect samples, BHGE says that the FastTrak Prism service’s capacity – 16 discrete single-phase samples per run, and up to 13.4 liters of total fluid volume – provides operators with the representative fluids required for their strategic development and appraisal decisions in one drilling run, resulting in significant rig time and cost savings. Further, the FASTrak platform of sampling services has an extensive track record with hundreds of samples collected worldwide.

Continual measurement and analysis of pumped fluid during sampling operations makes it possible to easily and accurately monitor contamination and fluid properties before capturing the fluid sample. The FASTrak Prism service’s fluid chambers feature proprietary sample capture technology enabling it to achieve an enviable record of acquiring high volumes of high-quality samples with minimal contamination.

Multi-channel spectrometry extends the accuracy and reliability of the service, allowing customers to clearly distinguish between fluid types and improve their understanding of fluid properties, especially in complex flow conditions.

On a recent offshore project in Australia, BHGE says that the FASTrak Prism service captured a total of 26 samples—12 in the first well and 14 in the second—with a total sample volume of over 20 liters in the two runs—setting a global record for fluid sampling while drilling. Additionally, in a recent offshore project in Africa, the FASTrak Prism service met the operator’s fluid evaluation objectives, saved two days of rig time, and contributed to an efficient well completion, resulting in production that exceeded the target by more than 30%.