Industry reveals latest products and technologies at OTC 2017

Jessica Tippee

Assistant Editor

Cautious optimism could be felt throughout NRG Park in Houston at the recent Offshore Technology Conference. More than 64,700 attendees from more than 100 countries gathered at the 49th edition of the event that featured nearly 350 technical papers, 44 technical sessions, 13 panels, multiple poster sessions, and 24 topical breakfasts and luncheons. The exhibition floor covered 599,295 sq ft (55,676 sq m), including outdoor exhibits, and featured 2,470 companies from 43 countries.

Drilling and production

Many products and technologies were introduced for the drilling and production market.

Baker Hughes Inc. unveiled the DEEPFRAC deepwater multi-stage fracturing service. Using multi-position sleeves and patented flowback control technology, the service eliminates casing and cementing operations and simplifies fluid logistics by using ball-activated, multi-position sleeves that can be installed in open-hole wellbores containing drilling mud. This is said to enable rapid stimulation of 20-plus stages. This translates into greater reservoir contact, with an average opex savings of $30 million to $40 million per well. No tool movement is needed during the new service’s stimulation process. The sleeve’s ball activation enables continuous pumping from the first stage to the last, cutting the lower completion phase from weeks to days.

After stimulation operations are complete, Baker Hughes says that its IN-Tallic disintegrating frac balls allow production to flow without intervention. Patented Baker Hughes BeadScreen proppant flowback control technology built directly into the DEEPFRAC sleeve’s production ports provide increased reliability over conventional sand screens through higher burst/collapse ratings and improved erosion/plugging resistance, helping to ensure long-term, sand-free production.

Schlumberger launched the SpectraSphere fluid mapping-while-drilling service. This is the industry’s first service, the company claims, to deliver downhole fluid composition during drilling with real-time pressure measurements-while-drilling. Applicable in a variety of environments, from exploration wells to highly deviated development wells, SpectraSphere aims to lower risks associated with fluid analysis and sampling operations while enhancing well placement, maximizing reservoir contact, and ultimately boosting future production. The company also claims that the new service is the industry’s only service to enable real-time fluid mapping by providing fluid properties, including composition, typing, fractions, and gas/oil ratio while drilling. The reliable characterization of these properties is essential for estimating reserves, optimizing completions, designing surface facilities and meeting production goals. The service has been field tested in the Gulf of Mexico, Middle East, Africa, the North Sea, and offshore Malaysia.

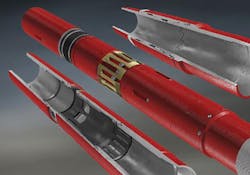

Weatherford International plc released a premium version of the RipTide RFID (radio-frequency identification) drilling reamer that incorporates advanced cutter technology. The RipTide RFID drilling reamer has been deployed in deepwater fields throughout the world. After encountering especially abrasive formations in the deepwater Gulf of Mexico, the company approached US Synthetic, a provider of polycrystalline diamond cutters, to explore new solutions for reaming operations in these fields. As a result of this collaboration, the pair said they each developed proprietary technologies. Weatherford developed the ReamSync borehole enlargement performance system, which includes a predictive cutter and formation interaction software used in the design of cutter blocks.

Concurrently, US Synthetic developed Deep Diamond cutters with improved thermal stability. Applied together, these technologies yielded an enhanced RipTide reamer that has demonstrated improved performance in highly abrasive formations in the deepwater Gulf of Mexico.

In addition, Weatherford also announced the commercial release of the WFX0 gravel-pack system. The first fully integrated, V0-rated gravel-pack system, it combines the gravel-pack string with a deep-set barrier. By leveraging several of the company’s technologies, the system enables gravel-pack completion of multiple open-hole zones in a single trip.

Emerson Automation Solutions debuted its Roxar salinity measurement system, which it claims provides accurate and real-time measurement of saline water in gas production well streams. Operators can use the equipment to quickly identify changes in the flow stream and the smallest amounts of saline water. This allows them to take immediate remedial action to prevent scaling, hydrate formation, and corrosion. The new system, part of the Roxar subsea wet gas meter, is based on microwave resonance technology. It provides quantitative and qualitative real-time salinity measurements in many types of field conditions, in particular high gas volume fraction/wet gas flows.

Caterpillar Oil & Gas introduced pump electronic monitoring system (PEMS) technology for well service operations. The company says that this can minimize downtime, preserve fluid end and power end components, and help avoid catastrophic failures. PEMS is compatible with Cat Triplex and Quintiplex pump platforms.

Siemens introduced the SGT-A35 RB gas turbine. The unit is said to addresses the need for more cost-effective solutions for the offshore oil and gas industry by increasing the power density of the topsides power generating equipment, thus reducing the required space claim. The lightweight, aeroderivative gas turbine can generate up to 38 megawatts and is integrated into a compact, lightweight Dresser-Rand package, which is up to 30% smaller and lighter than Industrial RB211 predecessors.

Subsea

Several technologies and products debuted for the subsea market.

Interventek Subsea Engineering launched an open water well control shear and seal valve that is designed for light well intervention (LWI) and workover operations, including large bore, deepwater and high-pressure/high-temperatures (HP/HT) applications. Using a newly developed, linear form of its patented Revolution technology, the open water well control valve provides safety protection during LWI, particularly in emergency disconnect situations. It can cut through obstructions and immediately provide bi-directional sealing protection at full working pressure. The use of resilient seals for fluid containment avoids the risk of rapid gas decompression. The separated cutting and sealing mechanisms within the valve means that its sealing surfaces are protected during cutting.

Flintstone Technology unveiled a subsea tensioned mooring system that is said to provide simple connection and disconnection, allowing mooring lines to be replaced faster than traditional methods. It also has the ability to tension at the seabed or mid-line, unlike traditional mooring lines designed for floating production vessels which depend on winches and fairleads mounted on the hull.

Delmar Systems unveiled the RAR Plus and the MOOR‐Max releasable mooring system. The RAR Plus is the next generation of Rig Anchor Release (RAR) that builds on the proven acoustic release technology by adding key features such as a manual backup release method and increasing the ultimate and release load ratings. In addition, the RAR Plus transmits both direct and indirect line tension measurements from internal sensors for real‐time display onboard the rig in a user‐friendly graphical user interface. It also is a key component in the new Delmar MOOR‐Max releasable mooring system, which provides a mooring system for MODUs to avoid storms or improve rig move efficiency.

Digital technologies

Companies also unveiled software technologies for the offshore oil and gas market.

Emerson introduced a new version of its Dynamic Lift Optimization (DLO) software. Use of the software, the company claims, can bring a typical site operating multiple wells a 10% improvement in production. DLO dynamically adjusts lift gas flows or electric submersible pump (ESP) speed based on the most recent well test curves. Once configured, it optimally allocates available lifting power to the wells to maximize production, while at the same time adjusting to changing conditions such as wells coming on or off, or compressor trips. The new DLO version facilitates cloud-based infrastructure, and its new graphical user interface is said to allow production engineers to safely and securely access critical field optimization data from any location with an internet connection. In addition, the software now uses the OSIsoft PI System - a scalable open data infrastructure and historian that provides common data architecture from the plant floor to board level.

Weir Oil & Gas launched a line of pressure control intelligent systems for high-pressure formations. Each of the products connects to a control unit via sensors that send real-time information from the equipment back to the control unit. The data is relayed to the customer in a secure, cloud-based portal, accessible by desktop and mobile devices and stored in Weir’s electronic data warehouse for historical reference. Should an issue with levels arise, the system will sound the alarm much sooner to ensure the operator has more time to adjust the flow from the choke or for the choke to adjust automatically. The Mathena mud gas separator intelligent system (MGS-ISC) measures and automatically controls liquid levels within the mud gas separator, while simultaneously ensuring MGS vent gas separation performance. The MGS-ISC helps to prevent overflows from occurring. The Mathena vent gas analyzer and intelligent flow meter system (VGA-ISF) integrates a gas-flow meter and vent-gas analyzer to measure gas flow rates and gas volume for methane and hydrogen sulfide. The Mathena ECO-tank intelligent system (ECO-ISL) measures liquid levels in the tank or other secondary containment unit. Designed to maximize safety and minimize environmental impact, it is said to be the industry’s first active, real-time monitoring system for containment levels. The Mathena frac flowback intelligent system (FFB-ISL) monitors flow-rate data and level change within frac tanks.

Lloyd’s Register unveiled its virtual reality (VR) safety simulator to help further support training and knowledge transfer in the oil and gas industry. The VR tool provides interactive simulations that close the gap between the abstract experience of a lecture and the concrete experience of navigating and handling actual objects on-site.

Spotlight awards

OTC’s Spotlight on New Technology Awards recognized 17 technologies from 14 exhibiting companies for their new and innovative products and services.

Halliburton earned two awards. The first was for the EcoStar electric tubing-retrievable safety valve. This is said to be the world’s first electric downhole safety valve. The valve eliminates hydraulic fluid to enable a fully electric completion system with zero risk of exposing electronics to produced wellbore fluids while retaining the same failsafe mechanism as today’s conventional safety valves.

The second was for the HCS AdvantageOne offshore cementing system. This system enables remote operations, has an integrated liquid additive system for precise slurry blending, and predictive maintenance capabilities with shore based monitoring to help preempt equipment-related non-productive time.

Fuglesangs Subsea AS received the award for the Omnirise MiniBooster. This is said to be the world’s first barrier fluid-less and seal-less pump intended for permanent subsea applications down to 9,842 ft (3,000 m). The system includes a subsea electric variable speed drive, and was successfully qualified as part of NOVs’ Active Subsea Cooler system in partnership with Statoil, Shell, Chevron, Total and GE. The company also has received the OTC Small Business Award, which supports and recognizes innovative technologies being developed by small businesses (less than 300 employees).

Schlumberger won two awards. The first was for the managed pressure drilling (MPD) integrated solution. This is said to be the industry’s first complete, all-OEM, reservoir-to-flare-stack deepwater MPD system. When MPD design, engineering, manufacturing, system integration, well engineering, and onsite well delivery services are delivered from one platform and from a single supplier, operators minimize rig footprint while maximizing drilling efficiency and versatility. The second was for the OptiDrill real-time drilling intelligence service, which enables continuous real-time condition monitoring by integrating a comprehensive set of drilling dynamics and mechanical information. The service mitigates drilling risk and improves performance by providing actionable information to continuously identify hazardous drilling dynamics events and trends, and recommending safe operating parameters.

Dril-Quip Inc. was also recognized for two technologies. The first was for the BigBore-IIe, a fully qualified wellhead system consisting of a DXe connection profile, integral high-capacity hanger lock-down, superior system fatigue, and high-capacity running tools. The system is said to provide cost savings by reducing the number of trips into the well, elimination of drilling/production lock-down equipment, and allows for reduction of casing strings. The second award was for the DXe wellhead connector. This is suitable for HP/HT and severe cyclic load environments, has a highly engineered locking profile and gasket design providing high structural capacity and high fatigue-resistance resulting in longer service life. The technology is validated beyond API-16A-PR2/API-TR7 requirements with both structural and fatigue physical testing.

Stress Engineering Services Inc. received the award for its real-time fatigue monitoring system. This was developed to provide field measurements of stress and fatigue on drilling risers, wellheads, and other subsea systems in near real time. The system is said to improve riser integrity management by using measured data and advanced algorithms at strategic locations to reconstruct stress and fatigue damage along the entire riser. It integrates this approach into a fully automated, real-time environment.

SBM Offshore won for the FPSOTurritella’s turret mooring system. The FPSO is the host facility for Shell’s Stones project in the deepwater Gulf of Mexico. The system incorporated a series of enabling technologies to become the deepest mooring system of any floating production unit, and the first disconnectable turret mooring system to support steel risers. These new technologies will facilitate future developments in ultra-deepwater, and of high-pressure/high-temperature reservoirs.

TechnipFMC was recognized for the 20k high-pressure/high-temperature subsea choke. It is designed to withstand life-of-field fatigue in HP/HT environments without the need for hydraulic fluids. It meets, or exceeds, API 17TR8. Its plug-and-cage design leverages proprietary HP/HT sealing technologies and the company’s G2i electric actuator, providing increased controllability over traditional hydraulic actuation technology.

Wild Well Control received the award for the DeepRange intervention tool. The system delivers a plug and abandonment solution in a riserless package. The ROV-driven technology offers a minimally invasive solution that maintains wellbore integrity while providing a cost-effective yet high-quality option that is claimed will change the way subsea P&A operations are done for years to come.

Sulzer won for the compact mass transfer and inline separation technology (cMIST). ExxonMobil Upstream Research Co.’s cMIST replaces conventional TEG towers and associated separator vessels to meet pipeline dewpoint specifications. The system achieves this goal with reductions in weight, footprint and cost. The technology for dehydration is licensed to Sulzer for onshore and offshore applications.

West Drilling Products, part of WeST Group, earned the award for the continuous drilling and circulation unit (CDU). This is the heart of the continuous motion rig technology, offering the world’s first continuous drilling operation, and is also the world’s first fully robotized circulation unit. The CDU reduces up to 50% of overall drilling time because it eliminates downhole problems associated with differential sticking and pressure fluctuations and reduces safety risk by removing all personnel from the rig floor during drilling.

WiSub was recognized for the Torden high power pinless subsea connector. Developed in collaboration with NOV, the tool is designed to increase connection reliability between BOP and lower marine riser package. This innovation is further standardizing AUV and ROV connections, combining patented high-speed data transfer with highly-compact resonant power transfer. Torden is said to deliver improved mating tolerances and reliability. The company also received the OTC Small Business Award.

TECHNI AS won for the B-annulus monitoring system (BAMSE). This is a pressure and temperature sensor for installation in the B-annulus of oil and gas wells. The system uses no active electronics in the inaccessible B-annulus and is designed for life-of-well reliability.

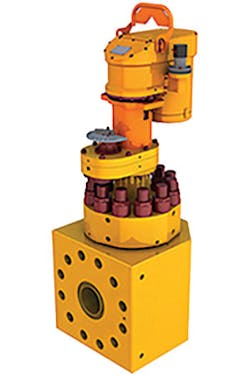

Samoco Oil Tools earned the award for the OneTrip, a BOP testing tool. In collaboration with Shell Offshore Engineering, Samoco engineered, manufactured, and tested the BOP testing tool. OneTrip can conduct required BOP tests in one trip, eliminating the need for multiple trips along the stack and reducing a rig’s idle time by a minimum of 50%.

Weatherford was recognized for the AutoFrac RFID-enabled stimulation system. The AutoFrac system enables efficient stimulation in open-hole sections of extended-reach offshore wells and remote operation of lower completion tools, and provides several options for tool communication that do not rely on control lines or mechanical actuation.

The annual event returns to NRG Park on April 30-May 3, 2018.