Optimized drillbit design cuts cost, time

Robert Ford

Smith Bits, a Schlumberger company

Offshore drilling is expensive, especially in deepwater, and there is a strong focus on reducing both development cost and time-to-production to reap the best return on investment.

Drill bits represent a small part of the capital expenditure, but their individual durability and rate of penetration (ROP) can significantly impact the overall cost of operations. Improving the speed of drilling provides cost savings and reduces time to production.

While many factors – including selecting the optimum drilling fluids and managed pressure drilling – impact drilling performance, the bit remains an essential component that can make the difference between economic success and failure.

Every oilfield target has unique geological features that present different challenges. In addition, there are a wide variety of operational constraints, well designs, drilling systems, and bottomhole assembly (BHA) configurations. To achieve optimum drilling performance, it is essential to identify and utilize bits with characteristics best suited for the particular downhole conditions they will encounter.

This article presents three examples from different parts of the world in which optimizing the bit design and drilling system improved performance and saved the operator time and money. The optimization process used proprietary drilling design functionality developed by Smith Bits.

Drilling design capabilities

The IDEAS integrated drillbit design platform – applicable to both roller cone and fixed cutter drill bits – delivers a true understanding of the dynamics of the rock-cutter interface. With 4D simulation of the well for which it is designed, the IDEAS process shows how a bit behaves as an integral part of the whole drilling system, including drillpipe, measurement-while-drilling (MWD) and logging-while-drilling (LWD) tools, reamers, stabilizers, and positive displacement motor (PDM) or rotary steerable system (RSS), resulting in a detailed graphic representation of the elements that impact drilling.

The software then designs and rigorously tests bit behavior in a virtual well with actual drilling conditions to analyze the rock-cutter interface, BHA configuration, drillstring behavior and directional response, and operational parameter changes. The virtual simulation capability enables drill bits certified by the design process to go from concept to field-proven performance faster than those designed with traditional processes involving multiple time-consuming field trials.

The i-DRILL engineered drilling system design process uses predictive modeling to identify solutions that minimize vibrations and stick/slip during operations, and optimize BHA performance for a given environment. Employing the IDEAS design platform, this drilling system design process quantifies the vibrations and ROP for a given drilling system as a function of time. This is accomplished by combining a bit-rock cutting model based on extensive laboratory testing with finite element analysis of the bit and drillstring.

Various combinations of drillbit options, drilling assembly components, drillstring designs, surface parameters, component placement, and overbalance pressures can be examined. The process can analyze the dynamics of the drilling assembly through multiple formations of variable compressive strength, dip angle, homogeneity, and anisotropy; a critical factor in obtaining optimal performance through formation transitions.

The virtual drilling environment, built using offset well data, surface and downhole measurements, and a thorough knowledge of products and applications, provides confidence in new technology and unconventional approaches without the risk and expense of trial-and-error on the rig.

The DBOS drillbit optimization system identifies the best drill bit for a particular interval to be drilled. This software-based system uses offset well data to choose a fixed or roller-cone drill bit with the appropriate combination of cutting structure, gauge protection, hydraulic configuration, and other critical characteristics. The process incorporates a thorough analysis of offset well data, including well logs, formation tops, mud logs, core analysis, rock mechanics, drilling parameters, bit records, and dull bit conditions.

The system comprises a geologic mapping program, well log correlation and analysis software, and proprietary algorithms for rock compressive strengths, bit performance analysis, and bit selection. Bit strategies can be developed based on input from a single offset well, a multiwell cross section, or a full-field mapping and regional trend analyses. A log plot called a bit performance analysis (BPA) presents key bit performance variables over the given drillability intervals, identifying which bit will be the most successful for drilling through specific single intervals or over multiple intervals.

A post-drilling analysis evaluates bit performance from available data such as real-time ROP, WOB, rpm, torque, and dull bit conditions. These results provide design and application engineering feedback for continuous improvement, and input to the DRS drilling record system—a collection of knowledge built from nearly three million bit runs in most of the world's oil and gas fields, including oil, gas, and geothermal wells. The database, initiated in May 1985, supports the decision-making processes of the IDEAS integrated drillbit design platform and DBOS drillbit optimization system.

Case study 1: offshore Indonesia

Total Exploration and Production (TEPI) had to drill a deviated wellbore through a thick shale/sand sequence to develop gas reserves trapped in Miocene age sand bars in a field offshore Indonesia. Historically, the 6,900-7,900 ft (2,100-2,400 m) tangent sections were drilled with a 9-in. PDC bit on an RSS. The lithology is mainly soft shale and abrasive sandstone, but sections also contain intermittent coal/limestone stringers and become increasingly interbedded with depth.

The well plan called for a 45° tangent section followed by sequential angle drop to 10° increasing verticality for the subsequent 6-in. production hole run. In the past, 97⁄8-in. PDCs run in the field suffered from unstable drilling, which resulted in performance degradation. The unwanted drillstring harmonics reduced overall ROP to an unacceptable level and caused vibration-induced impact damage in the harder formations. Field analysis revealed that 2- to 3-level dull cutter condition in the shoulder area resulted equally from abrasive wear and chipping/breakage.

To cut costs, the operator reduced the hole section size to 9½ in., but with the same objectives, which were to drill shoe-to-shoe in one run at the highest possible ROP with minimal shock and vibration. The challenge was to design a new-style PDC bit that could consistently drill from under the 10 ¾-in. casing shoe to section TD in one run, at a target ROP of 55 m/h or better, with minimal vibration.

The optimization effort was more complicated than normal because the hole size reduction occurred before engineers could benchmark 97⁄8-in. bit performance and capture critical field information. The lack of measurable target data would hamper the effort to improve existing 9½-in. bit performance because specific regions of the field are more difficult to drill than others.

A team of field engineers and bit designers analyzed relevant drilling data and concluded the existing 97⁄8-in. six-bladed matrix body bit with 16-mm cutters was the best base design and would serve as the starting point. The drillbit design platform was used to investigate downsizing the PDC bit and optimizing its cutting structure.

Drilling system design simulations were run to model bit and BHA behavior through a range of drilling parameters and the various lithologies encountered. Iterative design changes were made to the bit's cutting structure to ensure stable drilling and high ROP potential. The advanced modeling tool was used in combination with the drillbit optimization system, which pinpointed the unconfined compressive strength (UCS) of the shale at 3,000 psi with the sandstone fluctuating between 9,000 psi and 15,000 psi. The UCS study enabled technicians to select an in-house library rock sample that matched the field formation to replicate the fundamental shearing action in the laboratory.

Achieving the high ROP objective would also require improved bit hydraulics to rapidly evacuate the large amount of sticky drill cuttings that would be generated during drilling the soft shale formation. Engineers ran computational fluid dynamics to study fluid flow, and made adjustments to nozzle location and orientation until an optimized anti-balling configuration was found.

The combination of modeling and in-depth analysis of field data confirmed that the existing six-bladed matrix body PDC bit equipped with 16-mm ONYX premium PDC cutters had the best chance to deliver shoe-to-shoe performance at the highest possible overall ROP on a PowerDrive RSS. Based on these findings, a 9½-in. SHARC MSi616 high-abrasion-resistance PDC drill bit was identified as the bit candidate to accomplish the objectives.

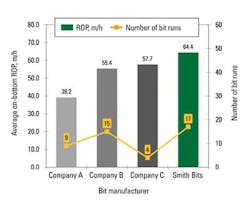

The new 9½-in. bit has since been run 17 times in the offshore field and has exceeded expectations by drilling an entire section in one run at a high median ROP of 64.4 m/h. The bit's best-in-field performance is 17% higher than target ROP, 12% greater than other products, and 51% faster than previous Smith Bits offerings. The bit successfully delivered all directional objectives, and rig personnel reported smooth drilling with minimal stick-slip and no shocks. The bit has set area ROP records including drilling 79.9 m/h on one rig and 80.9 m/h on another. Based on typical penetration rates (median ROP), running the new 9 ½-in. bit enabled TEPI to cut approximately four hours off on-bottom drilling time, representing savings of at least $30,000 per well.

Case study 2: offshore Ghana

Discovery of the Jubilee field, offshore West Africa, presented new challenges to the drilling industry, including drilling in a deepwater environment through sediments that transitioned rapidly from soft shale to hard and abrasive sandstone. An operator drilling an area of the field was suffering high-bit consumption rates, and the resulting number of trips was impacting the economics of the operation.

The overburden measured at 1 to 3 kpsi with an average interval length of 1,000 m (3,280 ft). Through the interbedded sandstone and shale reservoir section the average compressive strength was 7-10 kpsi with peaks up to 25 kpsi. The average interval was up to 400 m (1,312 ft). Bit failures were forcing at least four bit trips to complete a single section. Used bits from these wells were usually characterized by poor dull condition, including ring out and worn cutters. The operator wanted to reduce the trips needed to replace bits and, ideally, complete drilling of the reservoir sections in one run.

The proprietary modeling software, surface parameter optimization, drilling road map graphs, and correlation studies between adjacent wells were used to design a bit that could deliver the required performance. The design team tested several 12¼-in. PDC-bit designs based on the use of the PowerDrive RSS.

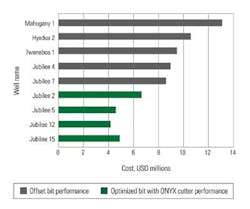

The bit that proved to have the best and most consistent performance was the 12¼-in. MDSi816LBPX with ONYX cutters. The chosen optimized PDC bit was the first to drill an entire 12¼-in. section in the field from shoe to TD in one run. Its performance saved two days of drilling time, estimated to be worth about $2 million. The bit's single-run capability has subsequently been recognized by several other operators and it has become a standard design for applications in this area.

Further improvement to the one-run success would involve risk, and engineers had to weigh the prospective gain against the potential loss. In deepwater, particularly with a successful solution in place, high operating costs generally reduce the motivation to embrace change even if a potential cost-reducing solution could produce a significant economic impact. Achieving additional gains required an engineered approach to reduce the risks of deploying new solutions.

During the initial campaign the simulation models were constructed around standard rock types. However, the acquisition of new reservoir cores allowed direct testing on actual formation. This valuable new information became the basis for a new 12¼-in. PDC bit design and provided the justification for field testing.

The strategic placement of ONYX premium PDC cutters in the cutting structure contributed to further improvements in performance. These cutters are manufactured using an enhanced synthetic diamond manufacturing process that gives the new cutter superior abrasive wear and thermal degradation characteristics when compared to prior generations of PDC cutter technology. The cutter is designed to resist the spalling and chipping that shortens the life of other hard formation drill bits.

Additionally, different well plans called for a longer 17½-in. hole section. To solve the challenge, the operator considered using a different bit type and/or smaller hole size. Based on simulation results and an analysis of global offset data of both sizes, the smaller hole size option was selected. The initiatives have been extremely successful, culminating in two wells drilled in record time, with one of them reducing drilling time by 40%, and achieving upper quartile performance as measured using Rushmore data. This work has demonstrated that continuous improvement is possible, but where the cost of failure is high, a thorough engineering analysis is required to justify each change.

Case study 3: offshore Australia

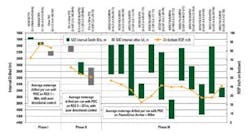

Extended reach horizontal drilling techniques were being applied to develop lower Cretaceous oil reserves offshore Australia. During the initial phases of the drilling campaign, the operator used a bent angle PDM drive system to construct the 9½-in. section to achieve the planned dogleg requirements and effectively geosteer in the reservoir. PDM drilling proved costly and time consuming, resulting in poor quality tortuous boreholes that impacted the horizontal reach that could ultimately be achieved.

In pursuit of faster ROP and longer holes, the operator experimented with two different RSS in place of the PDM, but with limited success, primarily due to their inability of these rotary systems to achieve sufficiently high dogleg severity (DLS) to maintain wellbore trajectory while drilling through a drop zone composed of unconsolidated reservoir sand.

Expensive side tracking and/or a PDM were required to reach TD, and in some cases, an additional trip was needed to continue drilling with an RSS. Rollercone tungsten carbide insert (TCI) drill bits were being used because of rig torque delivery limitations, and a three- year design initiative resulted in several new TCI footage and ROP records.

A team of well construction professionals brainstormed specific challenges of the operations to determine areas for improvements in performance and design an alternative drilling system that would provide precise trajectory control and the capability to drill the drop zone without side tracking or tripping for a BHA change out.

The team concluded that the PowerDrive Archer high build-rate RSS could meet the DLS requirements that would enable it to cross drop zones and steer through obstacles that proved difficult for standard RSS while also delivering superior performance compared to PDM drilling systems. Its increased DLS capability gives control in unconsolidated formations and the ability to punch through hard stringers. All external parts on the RSS rotate – a feature that reduces the risk of mechanical or differential sticking and improves wellbore quality for easier well completion.

To realize the full benefits of the new BHA would require a system-matched PDC bit with suitable blade count and cutter configuration to ensure optimal directional response and drillstring stability. Other changes included a switch to water-based mud, a reduction in hole size to 8 ½-in., and rig modifications to provide the required torque to efficiently drive the SHARC high-abrasion-resistance PDC drill bit and BHA. Since most of the offset wells were drilled with a rollercone and PDM assembly, only six applicable PDC/RSS runs were available for engineering assessment.

A dull-grading exercise revealed bit body erosion caused by cuttings recirculation and vibration induced cutter chipping. The designers used the drillbit design platform to evaluate several different PDC cutting structures in a virtual environment that matched the operator's application to determine which base design offered the best combination of directional responsiveness, high ROP potential, and stability for the directional profile and formations to be drilled.

Over 200 simulations were run, after which iterative changes were made resulting in the final 8½-in. SHARC MDSi716LKUBPXX bit design. Specific modifications included a diamond-impregnated depth-of-cut control feature to reduce torsional vibration and ensure blade top durability; computational fluid dynamics-based changes to the hydraulic layout to mitigate cuttings recirculation; a high-erosion resistant matrix bit body; and modified gauge pad length with diamond protection.

The application of the custom-designed SHARC bit on a PowerDrive Archer RSS successfully delivered the required directional work on the two wells/five laterals and consistently corrected inclination even while drilling the extreme drop zones where ROP reached 300 m/h.

The improved directional control and well placement capabilities eliminated the need for drop zone correction sidetracking. The BHA delivered a smooth high-quality wellbore significantly reducing the time required to run openhole sand screens. This increased operational efficiency saved the operator an estimated $9.8 million.

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com