New flexible retrofit device aims to improve offshore crane precision

Offshore staff

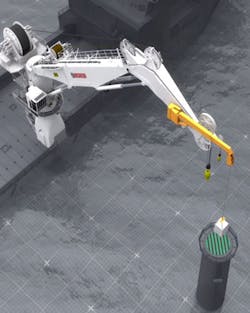

HELSINKI, Finland– MacGregor, part of Cargotec, has introduced the 3D motion compensator (3DMC), a flexible retrofit device that is designed to enhance the load-handling precision of an offshore crane even in challenging sea states.

The 3DMC can be fitted to the knuckle jib of a broad spectrum of new or existing MacGregor subsea/offshore cranes. It compensates for the roll, pitch, and heave motions of the vessel to minimize any movement of the load in relation to a fixed point in space.

During operations that require a greater degree of precision than that available from the standard crane, such as transferring equipment to or from offshore wind turbine structures or any fixed platform, the operator can opt to use the new device.

The new device has been designed for easy installation, the company says, and makes use of the existing hydraulic power unit and control system of the crane. The 3DMC/crane interface is designed so that the unit can be swiftly mobilized to a crane with the relevant fittings. This allows flexibility within a fleet of vessels that can share one or several 3DMCs between them.

The new equipment is fully incorporated into the crane’s control system so that all operations are performed from the existing interfaces in the crane cabin. When not required, it remains fixed to the side of the crane’s knuckle jib allowing normal lifting operations using the main and whip winches.

11/15/2016