Alfa Laval has developed a dual-nozzle cleaning machine for chemical and product tanks onboard ships. The Gunclean Toftejorg i65 D incorporates the same basic features as the single-nozzle Gunclean Toftejorg i65 S, introduced in 2006, but with numerous advances, including a patented hysteresis clutch.

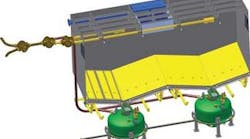

According to the company, dual-nozzle machines provide clear advantages for certain ships and their cargo operations. Single-nozzle systems, which operate in a helical pattern with a small pitch angle, can take hours to achieve full coverage. Dual-nozzle versions, which spray cleaning fluid in a criss-cross pattern, can reach all tank surfaces much more quickly. This shortens the cleaning cycle, and cuts the amount of cleaning fluid consumed.

Dual-nozzle machines also strike two points of the tank surface simultaneously. This, combined with the distributed cleaning pattern, ensures more even heating of the tank surfaces on ships that employ heated media in their cleaning applications.

The i65D’s hysteresis clutch dispenses with the need for a shaft penetration between the turbine and gearbox. The clutch also requires no mechanical or lip seals, thereby eliminating a potential source of gas leakage and cargo contamination.

Additionally, it resolves operational concerns associated with standard magnetic clutches. The latter, which incorporate one strong magnet on the turbine side and another on the gear side, must be synchronized for the gear transmission to engage. Should water hammering or sudden pressure surges arise, the magnets may slip, halting the cleaning cycle.

The i65 D’s clutch comprises a hysteresis plate on the turbine side and numerous super-magnets on the gear side. This combination generates an even magnetic field, Alfa Laval claims, which requires no synchronization and protects the clutch in the event of water hammering/pressure surges. An optimized turbine and the use of ceramic balls instead of conventional ball bearings also serve to maximize power transmission, as well as limiting gear system friction.

No programming is needed to optimize the cleaning pattern, the company adds, and the machine’s speed can be adjusted topside without interrupting the cleaning cycle. Using the hysteresis clutch, the machine can be speeded up or slowed down by altering the distance between the magnets and the hysteresis plate. So there is no need for a speed adjustment shaft and no seal to maintain or replace. As a result, Alfa Laval maintains, the i65 D is less prone to wear, with a lower life cycle costs than other dual-nozzle systems.