Low-salinity, polymer injections techniques help enhance recovery

Euan Duncan

Mark Burchell

BP Exploration

As operators look to maximize recovery from existing fields, enhanced oil recovery (EOR) techniques are becoming increasingly important in mature offshore basins. BP has been employing several EOR techniques at a number of its North Sea fields and is planning two additional projects in the region in the near future.

There is obviously a range of technical lessons to be learned for each EOR technique, but aligned with this there needs to be a careful process of confidence building, from company management down through all the disciplines. The challenge for the industry in the North Sea is how to build this confidence quickly enough with the relatively short time scale remaining for the infrastructure in the basin.

The goal here is to share some of the lessons learned from BP's EOR projects in the North Sea. The learnings are derived from EOR projects, but they can relate to any new project with a significant level of technology delivery or complexity.

EOR background

BP's first experience with EOR came from miscible gas projects on the Alaskan North Slope. The company then went on to manage three separate water alternating gas (WAG) schemes in the North Sea, in the Miller, Ula, and Magnus fields. The Miller WAG scheme started in 1998, and Ula and Magnus WAG followed.

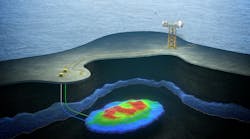

BP has now sanctioned a low-salinity water injection scheme (Losal EOR) in the Clair field to start up in 2017 and is planning a polymer flood in the Schiehallion Q204 field redevelopment.

To help categorize the learnings from these EOR schemes, it is first useful to describe a method to break down field recovery into four component parts, or efficiency factors. The "efficiency factors" diagram illustrates how recovery factor for an oil reservoir can be broken out into four categories:

Pore scale. This is the microscopic sweep efficiency at a pore scale. Much of the oil is bound to the rock grains or is bypassed in secondary porosity

Sweep. This describes what fraction of the rock is swept both areally and vertically on a field wide scale

Drainage. This relates to how much of the reservoir is connected to the wells (e.g. the field may be compartmentalized by faults or layering)

Cut offs.This describes how much production/recovery is lost through curtailment of well, plant, or infrastructure life for design performance, integrity, or economic reasons.

In an enhanced oil recovery scheme, the primary targets are pore scale efficiency improvement (e.g miscible gas and LoSal EOR) and sweep improvement (e.g. polymer). In addition, an EOR scheme will probably need to extend field life and usually require additional wells. This brings a secondary benefit in that the production facility is then available to both continue base production and to add new wells and satellites. Most EOR schemes need these associated benefits to make the whole scheme economic.

Clair Ridge

The Clair field is largest discovered hydrocarbon resource on the UKCS. It is operated by BP (28.6% equity) and is co-owned by ConocoPhillips (24%), Chevron (19.4%), and Shell (30%). The field is located 75 km (46.6 mi) West of Shetland in water depths of around 150 m (492 ft) and extends over an area of some 220 km2. The reservoir is made up of fractured sandstones of Devonian to Cretaceous age with current interpretations suggesting a total field stock-tank original oil in place (STOIIP) in excess of 7 Bbbl of 22-23°API oil.

Development of the Clair reservoir is progressing as a phased development. The first phase targets approximately 1.5 Bbbl STOIIP. This used a relatively small steel platform with 28 well slots and started production in 2005. Having proven the viability of the reservoir for waterflood for the second phase, Clair Ridge was appraised from 2005 to 2008, with sanction in 2011 of a 36 slot twin steel jacket. This targets a structurally higher area of the reservoir with approximately 2.5 Bbbl STOIIP.

Through the BP EOR screening process, LoSal EOR was defined as the most applicable technique for Greater Clair. The reservoir complexity and viscous fluid properties ruled out gas injection as an EOR technique. Other chemical EOR techniques are not currently economic, but may be used in future phases.

Low-salinity water injection is a recently developed EOR process that improves microscopic displacement efficiency by modifying the reservoir wettability. This has the effect of mobilizing more of the oil behind the displacement front and increasing recovery. The recovery process involves injecting brine, with a low salinity.

While low salinity EOR generally requires a lower upfront capital investment than a gas injection project, there is still a significant addition to the standard waterflood system. For Clair Ridge, a seawater reverse osmosis plant with a capacity of 145,000 b/d and additional manifolding is required. This required an additional mezzanine deck, a weight increase of 1,000 metric tons (1,102 tons) and a power increase of 6 MW.

In addition to the EOR increased recovery benefit, there are additional benefits of injecting lower salinity water:

• Reduced scaling tendency

• Less sulphate injection could help reduce H2S generation in the reservoir.

These benefits significantly help the economic case for a low salinity flood.

The following points summarize the lessons and key success factors from the current stage of the Clair Ridge project.

Internal confidence. It was critical to develop internal confidence within BP to overcome resistance to perceived complex design and engineering. To develop this confidence the following steps were followed:

• Establish a mindset that LoSal EOR is the default option for a waterflood

• Make extensive core measurements and simulation of reservoir processes

• Use results from a LoSal EOR field trial at Endicott in Alaska

• Create a high degree of integration and collaboration between field and research teams

• Ensure that all components of membrane systems for delivery of desalinated water were already used elsewhere and ready for installation and operation

• Implement and share results from a robust operational and technology risk assessment process.

External confidence. As important as developing internal confidence in the process was the engagement of the partners in Clair Ridge. This required significant interaction with Clair Ridge co-venturers in developing shared understanding of the benefits and risks.

Intellectual property. It was important to establish clear internal understanding on what is intellectual property (IP) and what can be shared.

Schiehallion redevelopment project

The Schiehallion and Loyal fields were discovered in 1993/94 and comprise oil accumulations with localized small gas caps trapped in several stacked and channelized deep marine turbidite reservoir intervals of Palaeocene age. The original field development plans involved an FPSO to target a base case recovery factor of 37% from 18 subsea horizontal producers supported by up to 12 injectors. The host Schiehallion FPSO was designed and constructed under the CRINE (Cost Reduction in the New Era) philosophy in a time of and $10 to $15/bbl oil prices. First oil was achieved in July 1998.

The Quad 204 project is the redevelopment of the Greater Schiehallion area. The field redevelopment is driven by two main factors: the deteriorating operability of the existing FPSO, and the recognition of significantly greater resources in the field and the surrounding area. It was decided in 2008 to replace the original FPSO with a new turret-moored FPSO.

The project initially assumed the use of a secondary water flood recovery mechanism (with produced water and seawater injection). However, the field was subsequently identified as a potential target for the application of EOR using a polymer to viscosify the injected water. In Schiehallion, a large part of the benefit of polymer is that through reducing the mobility of the water, less water is produced which frees up valuable plant capacity for more infill wells or tieback opportunities.

The pre-appraisal phase was primarily driven by the subsurface team. The overall result of the pre-appraisal depletion planning exercise was to indicate a strong bias for a facility in excess of 500 MMb/d of total liquid processing capacity, oil capacity of 150-200 MMb/d, and gas compression of 250-300 MMcf/d. In essence, the commercial assumptions agreed between the co-venturers were indicating that producing everything as quickly as possible created the most value. Among other drilling and subsea technologies, polymer EOR was taken forward to the appraisal phase.

The Quad 204 project entered project appraisal with a high degree of subsurface optionality coupled with a facility analysis that was quite basic.

The approach taken was to:

• Build 16 customized depletion plans covering four offtake rate options ranging from 250,000-500,000 b/d and four development options. This was done since it was recognized that each development option and max rate option led to different life of field depletion plans. In the Q204 appraisal phase the four development options considered were:

-Refurbishment of the existing FPSO

-A new FPSO/subsea development

-A combination new TLP with embedded drilling/subsea development

-A new semisubmersible (with or without drilling capability)/subsea development

• Assess each option using matched pair analysis against a basket of measures employing a subjective technology readiness factor alongside the usual table of commercial and project metrics to supported the inclusion of polymer EOR

• Use life-of-field vision as an influencing tool. BP and its partners worked to develop a holistic life of field "vision" for each integrated facility solution. This proved a critical step in providing the basis for concept selection and, ultimately, securing final sanction for the project.

The Schiehallion project progressed through concept selection and into the execution phase. In April 2010, the Quad 204 project co-venturers confirmed that the greater Schiehallion redevelopment would progress on the basis of a newbuild FPSO. The Quad 204 project is currently in the execution phase with the new FPSOGlen Lyon under construction at the HHI yard in Korea.

Select phase work already undertaken showed that a polymer flooding scheme was viable, with attractive economics for both base case and reasonable downsides. The Schiehallion partnership therefore decided in November 2010 to incorporate polymer EOR facilities in the basic vessel construction, with the intention of justifying polymer EOR start-up after stable base production had been achieved.

During the course of the Quad 204 project concept selection phase, some uncertainties and schedule pressures emerged relating to the EOR scope which would not be resolved within the timescale of the main project. There are several areas of performance critical for polymer EOR success that need further study such as the behavior of polymers through the delivery processes. It was therefore decided to incorporate these items, and all other elements necessary to successfully implement the EOR scheme, into a separate project to start in the appraisal phase.

Key learnings from the project to date are:

• On a large complex project, even from an early stage, linear project design is probably the wrong approach, even in the pre-appraisal phase. The pre-appraisal team needs to include a broad range of disciplines including facilities and commercial. During the appraisal phase, two tools were used:

Use of depletion plans on all options. This required parallel front-end loading work on key facility constraints and the involvement of all disciplines. The physical parameters of alternate concepts led to the realization that facility choices would lead to very different life of field depletion outcomes.

A clear life-of-field vision for alternate options. This enhanced communication internally, and with co-venturers and contractors.

• There is aclear bias to be inclusive of all options. While this can, on the face of it, provide strong commercial impetus to the project, the enduring complexity of having to understand so many option combinations can significantly slow progress, thereby potentially destroying value.

• The technology readiness level system employed by most operators discourages the development and proving of "new" technologies in parallel with project front-end engineering. There is a clear preference for technology deployment to be proven prior to inclusion in the engineering scope.

• In a project as complex as the Schiehallion polymer EOR project, it helped to run a separate project to create focus on the specific deliverables, and to link effectively to the parallel Q204 FPSO major project.

The more general lessons on EOR projects are:

• While EOR is initiated in a subsurface world, it lives and dies by the success of its integration into a complex development scheme involving all disciplines.

• Confidence in the technology is critical to success, and when initiating a new technology project the focus on building confidence within the company and externally is vitally important. •

Acknowledgment

Based on a paper presented at the Deep Offshore Technology International Conference held in Aberdeen, Scotland, Oct. 14-16, 2014.