Editor's note: This story first appeared in the January-February 2023 issue of Offshore magazine. Click here to view the full issue.

By Ariana Hurtado, Editor and Director of Special Reports

Subsea compression was designed to reduce costs, increase production and improve safety (being remotely operated) as well as provide a lower carbon footprint. Equinor is the leading operator of this technology with its Gullfaks and Åsgard projects, but also noteworthy are Shell’s Ormen Lange and Chevron’s Jansz-Io.

Åsgard’s all-electric subsea gas compression

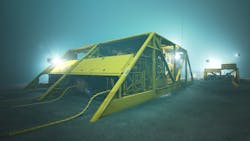

Aker Solutions delivered and installed the world’s first all-electric subsea gas compression system in 2015 to the Åsgard Field offshore Norway, and it is among the largest developments on the Norwegian Continental Shelf. It took five years from the project’s start to first gas in 2015.

Equinor commissioned the equipment because the natural pressure in Åsgard’s reservoirs would otherwise have been too low for stable flow. The subsea system is expected to boost recovery from the Equinor-operated field by 306 MMboe.

“Placing the compressor on the seabed spares the enormous cost of building and operating an offshore platform,” Aker Solutions stated on its website. “Moving the compressor closer to the wellhead increases production because of a lower pressure drop in the pipeline downstream, hence, the power required is lower compared to the alternatives. Subsea compression is also an ideal solution for deepwaters and harsh climates.”

The Åsgard system comprises modules for two identical trains of compressors, pumps, scrubbers and coolers. Aker Solutions’ compression module provides a minimized number of moving parts and supporting systems. For example, the bearings are magnetic and do not require a lubrication system and need only low-voltage power for their operation, the company explained. The compressor and its high-speed electric drive motor are housed in a single, hermetically sealed enclosure, and motor and bearings are cooled by process gas.

Aker Solutions boasts, “Since 2015 the two compressor units at Åsgard have achieved design performance figures of more than 99% availability, and with a significantly lower carbon footprint than a comparable topside installation.”

In December 2021, Aker Solutions secured a contract, worth between $20 million and $70 million, from Equinor to deliver engineering, procurement and construction (EPC) of a subsea compression module for subsea installation at Åsgard. The scope covers EPC of the fifth subsea compression module to be delivered by Aker Solutions for the Åsgard subsea gas compression system. The work started in late 2021, and the module is planned to be ready for delivery in August 2024.

Maria Peralta, executive vice president and head of Aker Solutions' subsea business, stated in a 2021 news release, “The continued Åsgard development demonstrates how we can help further enhance recovery rates at existing fields, while maintaining and reusing existing infrastructure and subsea equipment. It also demonstrates the value of Aker Solutions’ modular compression system, which is scalable and flexible to support enhanced production at declining reservoir pressures.”

Working with MAN Energy Solutions, the existing compression modules have been undergoing refurbishment and upgrading so the system can handle a higher compression, thus enhancing production and extending the field’s life as the reservoir pressure declines.

The Åsgard Field is 200 km (124 miles) offshore in water depths of about 240-310 m (787-1,017 ft). Gas moves to markets in mainland Europe via a pipeline to Kårstø, with about 11 Bcm/year supplied to European customers.

Gullfaks subsea wet gas compressors

Located in the Tampen area in the Norwegian North Sea, Gullfaks is the first oil field to be developed and operated by Equinor (formerly Statoil), producing first oil back in 1986.

Fast forward and Gullfaks became the world’s first subsea wet gas compressor project. According to a 2016 OTC paper, the subsea compressors began boosting the unprocessed gas well stream containing liquids to Gullfaks C in 2015 and will continue until 2030. The compressor station is equipped with three future hubs for tie-in of additional fields in the area, which enables flexibility to the system.

The system’s main components comprise two multiphase compressors with individual recirculation systems, two subsea process coolers, one flow mixer and three bypass headers. The flow mixer, located at the inlet of the station, is designed to dampen out liquid slugs and provide an equal homogenous split of multiphase flow to the two compressors when operating in parallel. The subsea cooler is designed to cool the well stream before compression to limit the compressor discharge temperature below the flow line design temperature, in addition to increasing compression efficiency, according to the OTC paper.

The wet gas compression system was also designed to eliminate the need for conditioning of the well stream. The wet gas compressors have no requirements for an upstream separation facility or an anti-surge system, which is designed to simplify the subsea system requirements.

Like Åsgard, the Gullfaks subsea compression station also started up in 2015. Shortly after, subsea compression halted and was taken offline following a chemical leak on a 16-km umbilical line to the Gullfaks C platform. However, the company said the leak had nothing to do with the compressors. They were only removed because they could not remain in place without support from the umbilical. The issue has since been resolved.

In 2019 Equinor and partners Petoro and OMV received approval from the Norwegian Petroleum Directorate to extend the production life of Gullfaks until 2036.

So how does Equinor’s Hywind Tampen floating wind farm fit into the Gullfaks equation? The wind farm is supplying electricity to the Gullfaks offshore oil and gas platforms. The Gullfaks platforms were dependent on gas-based power and are now powered by the Hywind Tampen floating wind farm.

The first subsea cables were laid and connection was made to the Gullfaks A platform in the North Sea around the third quarter of 2022. Then power production from the first turbine in the Hywind Tampen floating wind farm in the North Sea started in mid-November. As planned, the power was delivered to Gullfaks A.

Equinor boasts that Hywind Tampen, located about 140 km from shore, is Norway’s first and the world’s largest floating wind farm, and it also says the wind farm is the first in the world to power producing oil and gas installations.

The Hywind Tampen partners are Equinor, Petoro, OMV, Vår Energi, Wintershall Dea and INPEX Idemitsu. The wind farm is expected to meet about 35% of the electricity demand of the Gullfaks and Snorre fields. Seven of the 11 turbines were scheduled to come onstream during 2022, with the remaining four already assembled and awaiting installation in 2023.

Ormen Lange subsea multiphase compression

Shell says natural gas from the deepwater Ormen Lange project offshore Norway meets about 20% of the UK’s gas needs. Located in the Norwegian Sea, Ormen Lange field development was sanctioned in 2004, and first gas was produced in 2007. Shell pipes the gas to a processing plant onshore Nyhamna. Once impurities are removed from the gas, the company sends it to the UK through subsea pipelines.

Shell is the operator of the project with a 7.8% stake, with partners Petoro (36.4%), Equinor (25.3%), INEOS (14%) and Vår Energi (6.3%).

In 2019 OneSubsea was awarded the frame agreements for an Ormen Lange subsea multiphase compression system.

In 2021 Shell and its partners took a final investment decision on a wet gas subsea compression project at Ormen Lange and submitted a plan for development and operation to the Ministry of Petroleum and Energy.

The project is designed to unlock an additional 30 Bcm to 50 Bcm of natural gas, increasing Ormen Lange’s overall gas recovery rate from 75% to 85%. This will be fed into the Norwegian gas export system, ensuring the continued supply to Europe, Shell said.

A wet gas compressor system will be installed on the seabed at 900 m depth close to the wellheads, increasing gas flow from the reservoir into the wells. The 120-km (75-mile) distance from the shore to the installations set a new world record for subsea compression power step-out.

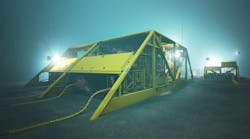

In second-half 2022, the first of two subsea compression stations built for Shell's Ormen Lange offshore field arrived at Horsøy, OneSubsea’s Centre of Excellence, outside of Bergen. The Ormen Lange Phase 3 subsea multiphase compression project is due to come onstream in late 2025, according to the project’s impact assessment.

Jansz-Io subsea gas compression

The Jansz-Io is a subsea gas compression project offshore Australia, with the aim to improve gas recovery at the Jansz-Io Field and maintain long-term gas supply to the Gorgon gas processing facilities on Barrow Island.

The Jansz-Io field development is a part of the Gorgon project. Chevron Australia is the operator with 47.333% interest, with partners Exxon Mobil (25%), Shell (25%), Osaka Gas (1.25%), Tokyo Gas (1%) and JERA (.417%).

The Jansz-Io gas field began operations in 2015 with its reservoir pressure expected to start declining from 2025 onward. The Gorgon partners took a final investment decision and sanctioned the $4 billion Jansz-Io compression project in 2021. The subsea compression system is projected to start operations in 2026, and it will be designed to sustain the peak production capacity of the field.

The Jansz-Io compression project will include a normally unattended floating field control station weighing about 27,000 tonnes, subsea compression infrastructure weighing about 6,500 tonnes and a 135-km-long subsea power cable. Chevron estimated the construction and installation activities would take about five years to complete, with work scheduled to begin in second-half 2022.

The floating field control station will be tied to the seabed by 12 mooring lines, while the subsea compression infrastructure will be installed on the seafloor about 1.36 km below sea level.

The Jansz-Io subsea gas compression system will include a complete compression station equipped with three compressor modules and two subsea pump modules, along with all-electric control systems and actuators, and a high-voltage electrical power distribution system.

A 135-km-long submarine cable and a 14-km-long land cable will be laid to transmit power from the Barrow Island to the floating field control station, which will further supply electricity to the subsea compression system.

The compression project is also expected to serve future back-fill fields connected to the Jansz trunkline.

- Aker Solutions: EPC for an all-electric subsea gas compression system, FEED and provision of dynamic subsea umbilicals;

- MAN Energy Solutions: supported Aker Solutions in the FEED study

- Worley: engineering, design and construction management services for power transmission and communication components as well as pre-FEED and FEED phases;

- ABB: supply of overall electrical power system;

- Baker Hughes: supply of a subsea compression manifold structure, module and foundation as well as a horizontal clamp connector system and subsea controls;

- Saipem: transportation and installation activities, scheduled to start in 2024; and

- DSME: building a field control station, scheduled to be completed by third-quarter 2025.