Editor's note: This article first appeared in the July-August 2023 issue of Offshore magazine. Click here to view the full issue.

By Bruce Beaubouef, Managing Editor

Unmanned or uncrewed surface vehicles (USVs) are being increasingly deployed for the offshore inspection and survey market, driven by an autonomy that helps operators lower personnel risks; gain better and more data at lower costs; and reduce fuel consumption and related emissions, as compared to traditional vessel-based operations.

USVs operate with various levels of autonomy, with some being controlled from a remote location, while other vehicles are fully autonomous.

USVs are now being deployed for structural inspections and integrity assessments for a range of offshore oil and gas facilities, and the vehicles are also being deployed to inspect facilities in the growing offshore wind market, usually in tandem with an electronically powered and controlled ROV.

Unmanned surface vehicles are also being used for metocean measurement campaigns that will help offshore wind energy developers reduce uncertainty about production.

In addition, unmanned vehicles are also being used for various seabed mapping projects, not only for offshore energy producers but also as part of data-collection efforts for marine environment and scientific research programs.

In the future, it also expected that USVs will play a key role in project permitting, particularly with regard to avian survey and monitoring, and marine mammal observations.

Oil and gas asset inspections

There have been a number of USV deployments for the offshore oil and gas industry. Earlier this year, TAQA Netherlands and Fugro completed an offshore integrity inspection campaign in the Dutch North Sea, using a USV in tandem with an electrical ROV (eROV). Fugro deployed one of its Blue Essence USVs and a Blue Volta eROV for the survey, which was remotely controlled via a satellite link from onshore operations centers in the Netherlands and Aberdeen.

The pilot project involved inspection of two platforms and more than 40 km of offshore pipeline, and comprised a multi-beam survey, depth of burial, visual inspection and cathodic protection assessment of pipelines between various offshore platforms.

In addition, the Blue Essence vessel and the eROV performed remote structural inspections that included visual checks, cathodic protection assessment, and a scour survey to ensure the integrity of TAQA’s facilities. Acquired geo-data, accessed in near-real time, was used to inspect the offshore facilities and the surrounding seabed environment.

The uncrewed integrity inspection was said to have resulted in a 95% reduction of CO2 emissions, the companies added, requiring only 5% of the fuel required by traditional manned offshore inspections. Typically, these activities would deploy about 70 people onboard a surface vessel, so the safety risk was also reduced, the companies said.

More recently, the UAE’s Ministry of Energy and Infrastructure gave the go-ahead for subsea inspections using USV technology. In April, the ministry awarded Fugro’s uncrewed surface vessel Fugro Pegasus full navigation licensing. According to Fugro, the 12-m Blue Essence over-the-horizon vessel is the first in its class to attain full registration in the Emirates. SEA-KIT International constructed the vessel, which is designed for inspecting subsea facilities. Teams at Fugro’s onshore remote operations centers worldwide say they can control the vessel remotely, which will lead to a reduction of 95% in emissions compared to conventional vessel operations.

USVs are also being deployed in other locations. Last year, Sulmara Subsea reported that it had successfully completed a pipeline inspection survey offshore Trinidad for BHP Petroleum (now Woodside Energy) utilizing an unmanned survey vessel.

The WAM-V 16 (wave adaptive modular vessel), produced by Ocean Power Technologies (OPT), is a class of autonomous watercraft that uses suspension technology to improve seagoing capabilities. Prior to the project, Sulmara said that it conducted extensive sea trials stateside to ensure peak performance of the system.

As a result, the company was able to complete the high-resolution shallow-water pipeline survey utilizing side scan sonar, a sub bottom profiler, and multibeam echo sounder without the use of a traditional survey vessel, thus reducing the overall carbon footprint for the project.

Offshore wind deployments

USVs are also gaining traction in the growing wind market. In April, Fugro announced that it had performed the first fully remote inspection of offshore wind farm facilities using one of its Blue Essence uncrewed surface vessels and the Blue Volta eROV.

The inspection took place at the Aberdeen offshore wind farm in the central UK North Sea (also known as the European Offshore Wind Deployment Centre), with funding from Vattenfall and the Offshore Renewable Energy (ORE) Catapult. The eROV, launched and recovered remotely from Fugro’s remote operations center in Aberdeen, undertook inspections of wind turbine structures to assess their stability and safety.

By using data from a deepwater multibeam echosounder sensor on the hull of the vessel, the team was able to generate a detailed map of the seabed area. Vattenfall accessed the acquired geo-data to inform its decisions on asset maintenance.

Meanwhile, Ørsted says it has designed and developed the first USV in the industry for offshore metocean measurement campaigns. The measurement data will help lower uncertainties in the expected annual energy production for new offshore wind farms.

Ørsted, who has patented the USV concept, sees enormous potential in the technology and has initiated a serial production based on the successful prototype USV, which is named Hugin USV. It is designed for continuous operation in the harshest offshore conditions for a year at a time. The USV has a built-in navigation system, which enables it to transit from shore at various degrees of autonomy, and it can be controlled both in line-of-sight or from a beyond-line-of-sight remote control center.

The USV is designed as a generic sensor platform and can collect large amounts of data on, among other things, the wind conditions, the state of the seabed, and biological and ecological measurements, all dependent on the sensor instrumentation chosen for a given operation. The broad range of measurements collected by the USV is essential for Ørsted’s early-phase development activities prior to the construction of new wind farms.

The USV concept was invented by Ørsted employees and has been patented. The design, development, construction and testing of the prototype USV was conducted as part of Ørsted’s innovation program in collaboration with selected industry partners. The prototype USV was constructed by the Danish shipbuilder Tuco Marine Group, and the USV control system delivered by Maritime Robotics.

Frederik Søndergaard Hansen, program manager and co-inventor of the USV concept at Ørsted, said: “What’s so special about our USV concept is that it can bring our measurement equipment to and from our offshore sites without the need for large, specialized support vessels, and, while on site, it can operate autonomously for extended periods of time, measuring large amounts of data that can be sent onshore and processed in real time. The USV concept enables Ørsted to obtain a consistently high data availability, which is essential for achieving the highest possible certainty regarding the annual energy production for new offshore wind farms.”

The prototype vessel, Hugin USV, has been tested in Danish and Norwegian waters and has been operational during hurricane conditions, where it experienced waves up to 9 m in the North Sea. Hugin USV has also achieved type validation as a floating LiDAR system by DNV, enabling it to be used for commercial operations related to wind farm development.

In addition, Ørsted has started a serial production of a new class of USVs, which incorporates the learnings from the prototype and broadens the operational capabilities to include deepwater operations for future floating wind farms. The USVs in the new class are being constructed in Denmark by Tuco Marine Group, and the control systems will be delivered by Maritime Robotics. The expectation is to produce five new USVs by year-end 2023.

Seabed mapping

In addition to offshore energy-related deployments, USVs are also gaining a foothold for scientific seabed mapping projects. HydroSurv recently reported that it received funding that will enable it to continue its use of USVs to map seagrass coverage on the seabed in Cawsand Bay off Cornwall in the UK.

The company says that the funding, which will come from Innovate UK, will allow it to continue its partnership with the University of Plymouth, and enable it to further advance its USV mapping techniques and systems.

Building on previous collaborations with the University and Valeport, the project aims to generate a comprehensive picture of seagrass meadows as well as to characterize the environment in which they are growing, enabling ecosystem health to be determined from the same survey campaign.

The project will see HydroSurv’s fully electric USV data acquisition platform developed further to deliver comprehensive, seagrass monitoring using an acoustic ground discrimination system, coupled with video and environmental data collection from new hull-mounted and underwater sensor arrays. These include two specialist cameras and a laser range finder which has been deployed to a constant altitude using an intelligently controlled cast winch on the HydroSurv REAV-28 USV.

Elsewhere, SEA-KIT International reports that its uncrewed surface vessel Maxlimer has completed an initial survey of the Hunga-Tonga Hunga-Ha’apai volcano caldera in the South Pacific. The USV returned from an initial survey mission last summer inside the caldera carrying a “plethora” of data and imagery to fill important gaps in current understanding and knowledge of the seamount and water above it.

Hunga Tonga–Hunga Ha’apai is a submarine volcano in the South Pacific located about 30 km (19 mi) south of the submarine volcano of Fonuafo’ou and 65 km (40 mi) north of Tongatapu, Tonga’s main island. It is part of the highly active Kermadec-Tonga subduction zone and its associated volcanic arc, which extends from New Zealand north-northeast to Fiji. On this survey mission, clear signs of continuing volcanic activity were seen inside the crater, with high particle concentrations in the water that are consistent with earlier observations of ash in the water column.

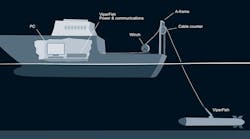

For the ongoing second phase of the NIWA/Nippon Foundation Tonga Eruption Seabed Mapping Project–TESMaP, funded by The Nippon Foundation, the USV Maxlimer has been equipped with a multibeam echo sounder to acoustically measure depth and state of the seabed. The vessel also has new winch capability for deployment of multiple sensors down to 300 meters, to obtain direct water column measurements. Maxlimer will be returning to the caldera for a more detailed survey to fill gaps and better target volcanic plumes and hydrothermal vents.

The 12-meter USV is being remotely controlled on its caldera missions from SEA-KIT’s base in Essex, UK, where a team of four operators work shifts for round-the-clock operation.