One initiative focused on offshore support vessels, drilling units and floating platforms integrates 3D scanning, digital twins, AI-driven analytics and UAV-based inspection to transform monitoring and maintenance.

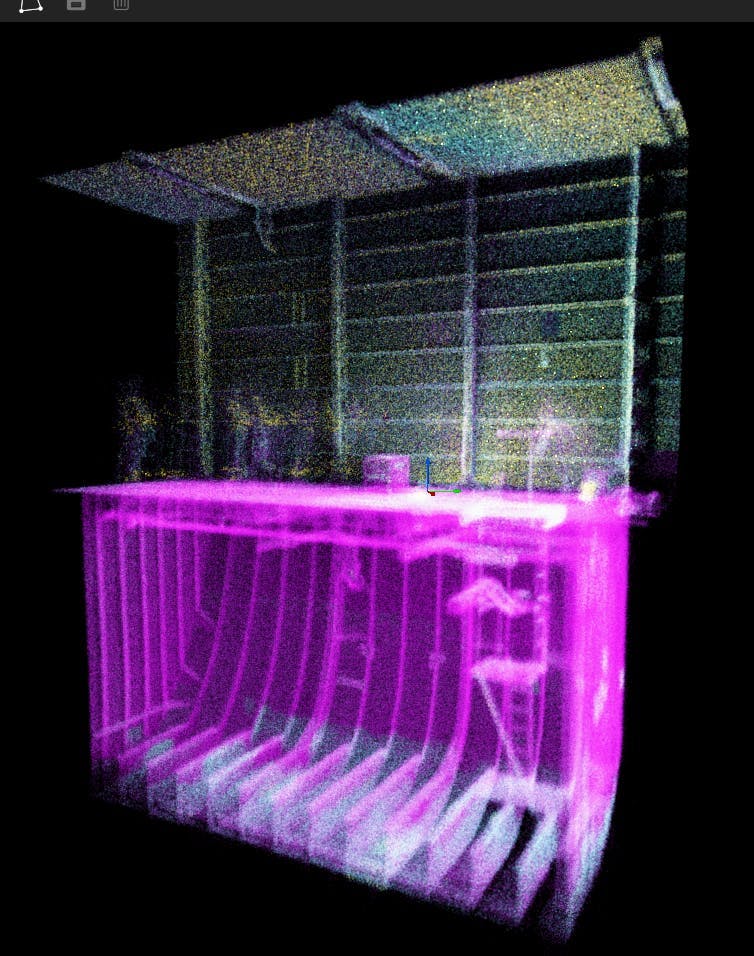

Using UAV-mounted LiDAR and ultrasonic thickness payloads, the system generates detailed 3D models that act as "living records." These models allow engineers to visualize structures, track degradation and predict future performance. Integrated with maintenance planning systems, they enable risk-based interventions, ensuring that resources are deployed where they are most needed instead of relying on fixed schedules.

Remote inspection has been particularly impactful. Traditionally, integrity checks required personnel to enter confined spaces or work at height using scaffolding or rope access. UAV-based inspections have reduced the need for these methods by up to 80%, while also cutting inspection time and costs. The initiative has secured classification society approvals from DNV and ABS, setting a benchmark for offshore practices.

Case study results

Since work began in May 2025 in the Middle East, deployment has already delivered measurable impacts:

- 15% reductions in maintenance budgets through predictive planning;

- 20% decreases in inventory value via integrated supply chain management;

- Up to 50% fewer equipment failures, boosting reliability;

- Projected 65% reductions in life-cycle upgrade and repair costs, through extended asset longevity; and

- About 10% lower insurance premiums due to reduced operational risk.

Beyond cost and safety, engineers report that live 3D models and predictive dashboards simplify decision-making, reduce workload and accelerate response times. By improving visibility into asset condition and life-cycle risks, the platform informs decisions around investments, upgrades and decommissioning.

From an environmental perspective, shifting to preventative maintenance reduces unnecessary travel, logistics and parts usage, which directly cuts emissions and aligns offshore operations with broader energy transition objectives.