Slipover jacket solution provides effective option for reviving aging platforms

Key Highlights

- The slipover method involves removing existing jackets and topsides while retaining wellhead infrastructure, then installing new structures built to current standards.

- The strategy enhances platform capacity for modern gas lift systems, improves safety features, and allows higher-capacity vessels and helicopters to access the platforms.

- Saudi Aramco has successfully implemented this method in projects like the Marjan field, with plans to upgrade multiple platforms, extending their operational life by up to 25 years.

By Muath S. Alturaif and Rameshkumar Kutti Ekanathan, Saudi Aramco

Saudi Aramco operates one of the largest offshore oil and gas networks globally, centered in the Arabian Gulf.

This network is crucial to the Kingdom’s energy output, with several offshore fields, including Marjan, being in operation for decades. Many platforms date back to the 1960s and 1970s, and rely on aging infrastructure, including wellhead platforms, tie-in platforms, pipelines, and other facilities constructed under older engineering requirements. Fixed offshore platforms are the most prevalent type of offshore structures installed by Saudi Aramco in the Arabian Gulf for extracting crude oil and gas.

The goal here is to present and discuss a solution that Aramco has employed to extend the life of such facilities, with the hope that the rest of the offshore industry, which operates such facilities, may find it useful in their own practices.

Although it is early days, the slipover solution has offered an effective method for upgrading existing facilities in various aspects. It has been shown to extend life and enhance the production efficiency of these aging offshore wellhead facilities. It does so through the implementation of slipover jacket structures and modular topside module with upgraded process and safety systems.

The goal in these efforts is to enhance production through gas lift systems while integrating new process and safety systems. In so doing, the “revived” platforms can then allow higher capacity vessels and helicopters to approach the platform, and thereby extend operational lifespans while leveraging the existing conductor systems, wells and x-mas tree assets.

This strategy aims to provide an efficient, risk-mitigated and future-ready solution for brownfield offshore developments. In summary, while Saudi Aramco’s offshore fields are vital, their aging infrastructure presents a substantial challenge that requires upgrades and modernization to sustain, enhance production and meet the safety standards for the next phase.

‘Revival’ challenges

Aging offshore production (wellhead) facilities, many of which have been in service for more than three decades, were engineered for the functional demands and operational requirements and standards of their time. After decades of exposure to the harsh marine environment, these facilities now face critical functional and operational challenges. Severe corrosion at boat landing and barge bumper structures are one of the common challenges with existing older platforms. These challenges complicate inspection procedures and equipment replacement due to the splash zone location. Older helidecks often do not provide the needed landing space for today’s helicopters, particularly with regard to landing space, and loading/lighting requirements. In addition to the outdated facilities, these topsides are generally unable to accommodate the latest gas lift manifolds and associated equipment.

Further, their layout often falls short of space and current safety access and egress requirements as per Saudi Aramco’s latest safety standards. In addition, there were often constraints in pile capacities which further limited the ability to upgrade with deck extensions. The limited capacity for upgrades has made traditional in-field modification increasingly non-feasible, and disruptive to production due to the uncertainties involved.

Limitations of infield upgrades

Upgrading aging existing facilities in place comes with significant challenges and risks. Brownfield modifications or upgrades for enhancing production typically require long shutdown durations, sometimes lasting months, which directly impacts production. The high number of offshore manhours increases safety exposure and risk, and the limitation of existing structures often means that only partial upgrades are possible. Moreover, unexpected deterioration discovered during the execution of work may lead to escalating cost and schedule impacts, further eroding the value of the upgrade efforts and strengthening proposals. For many aging assets, the scope and risk of brownfield modifications outweigh the benefits. But this very same fact is what makes a complete structural replacement by slipover method a more effective option.

Slipover jacket and topsides

This solution involves removing the existing jacket and topsides while retaining the wellhead infrastructure. This includes retaining the conductors, wellheads and x-mas tree assemblies and installing a new slipover jacket and topside fabricated to current standards and safety requirements.

Mohamed Al-Sadiq, Sr. Project Manager of Marjan Gas Lift Project at Saudi Aramco, noted that: “It is crucial to conduct all the associated studies early – assessing demolition challenges, selecting vessels and evaluating installation methodologies and offshore execution constraints – so [that] these issues can be addressed from the outset.”

A detailed assessment was conducted on one older platform that had been selected for gas lift upgrade. This assessment needed to evaluate the structural integrity of the platforms, factoring in the existing conditions and wellhead elevations with respect to the 100-year wave zone. Based on the evaluation of the platform, the common concerns identified were the corrosion in the boat landing areas and the barge bumpers along with the constraints in pile capacities. The assessment concluded that the platform did not meet the minimum ultimate lateral strength requirement as per the API RP 2SIM standard. For such scenarios, the slipover jacket was proposed as an optimal solution where the existing jacket substructures were considered not fit-for-purpose.

The slipover jacket structure was designed to envelop the existing conductor groups, ensuring minimal interference with the wells/conductor system infrastructure. The slipover jacket design was completed with particular focus on the slipover bay area, where provisions were made to ensure sufficient clearance for installation and adequate strengthening at framing elevations so that fatigue requirements were fully met. In addition, the design considered structural integration, while maintaining the integrity of the existing conductor system. Slipover installation at water depths ranging between 45 m and 60 m faces constraints such as limitations in hook height on most installation vessel cranes available in the region. In the demonstration project, the slipover structure was lifted fully above the existing x-mas trees, maintaining the required minimum safe clearance during the installation operation.

Slipover jacket installation

Importantly, the existing wellhead infrastructure was worked over to suit the wellhead system for lift gas capability, so that lean gas injection system would be readily available after the slipover installation was complete. This ensures that the upgraded platform becomes operational quickly post-integration, without the need for further significant interventions.

With regards to the slipover topsides, the process systems were designed for modular construction, with upgraded equipment, safety systems, and process systems to improve production from the existing wellheads.

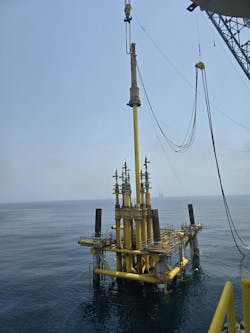

Saudi Aramco successfully installed a new jacket at an existing platform using the slipover method in the Marjan field. This tool place at a water depth of roughly 53 m, following the demolition of the original jacket and topsides. The installation was carried out using a heavy lift installation vessel, and the installation is designed to support the future integration of an upgraded gas lift topsides. The slipover method of life extension has been partially demonstrated, with the most critical phase of jacket installation successfully completed. The remaining integration, deck installation, hook-up and pre-commissioning activities are expected to proceed smoothly, reinforcing the strong potential for extending the wellhead platform’s operational life by an additional another 25 years.

Demolition challenges

Dismantling a jacket that has been in service for four decades presented technical and safety challenges. Topsides and jacket removal was sequenced into modular sections to preserve the integrity of wellhead/conductor system. Risk assessment and safety procedures, including temporary guides and remote cutting techniques, were required for the demolition of the existing structural assets while ensuring the well integrity.

Many structures may have undocumented modifications, grouted members, corroded and flooded members, and reduced wall thickness, making them unpredictable during cutting and lifting operations. During the jacket demolition in this demonstration case, grouted members were noticed which required different cutting methods and accordingly suitable tools were deployed to overcome the situation. Selecting the most appropriate cutting technique, whether abrasive water jet or diamond wire, required careful and detailed assessment of site-specific conditions. In addition, divers implemented precautionary measures to prevent unstable load distribution caused by partial cuts, ensuring safety and structural stability throughout the operation. Moreover, heavy marine growth can impair visibility for divers and ROV operators. Environmental protection measures, including the debris containment for pile cutting and noise mitigation to safeguard marine ecosystems, were critical during demolition. Above all, simultaneous operations were managed to maintain the well integrity while dismantling the interfacing and load-bearing structural members.

Installation complexities

Choosing the appropriate installation vessel is one of the most important yet unpredictable factors in slipover projects. During the front-end engineering design stage, vessel selection and installation study was not in scope, however criteria were outlined based on preliminary weight estimates and conservatively estimated hook height. Hook height is a critical parameter for a slipover jacket installation, as shown in the photo during the installation phase, where the structure was first lifted with sufficient clearance and then lowered to envelope the existing wellhead systems for safe installation. However, by the execution stage, actual weight information, limiting sea-state for installation, global vessel availability and accordingly weather window schedule was available. Based on these, execution contractor performed the necessary installation studies to assess the limiting sea state and probable weather window along with the minimum clearances at each phase of slipover. These clearances were maintained with the existing wellhead infrastructure for safe and efficient installation.

Safety culture

The slipover installation was carried out under methodically selected limited environmental sea state conditions, since the installation is highly weather sensitive due to the limited clearances around the existing wellhead infrastructure. Strict limits were imposed on maximum allowable wave height, current and wind speed to ensure safe and controlled installation.

Furthermore, during installation, Real-time survey monitoring is crucial. A survey system was utilized, which included pre-installed survey prisms on the jacket. This system enabled real-time monitoring of the jacket’s position relative to the existing wellhead infrastructure, with clearances displayed directly on the survey interface which ensured safe positioning, adjusting and lowering of Jacket throughout the installation duration.

Khalid Al-Sulaim, Director of Marjan Increment Program, observed that: “[The] Marjan Gas Lift Division capitalized on the slipover platform installation as a solution for the upgrades proposed to incorporate gas lift manifolds and associated piping system to enhance production. The decision made is cost-effective, avoiding lots of risk and schedule impacts from different packages within Marjan gas lift projects.”

Conclusions

Aging offshore platforms present a combination of structural, operational and safety challenges that cannot always be resolved through in-situ upgrades. The slipover jacket and topsides replacement approach provide a safer, risk mitigated and more robust way to extend life, enabling the integration of modern capacity and compliance standards while minimizing disruption to production.

When combined with strong leadership and early engagement of specialists from the Consulting Services Department, part of Saudi Aramco, this method transformed a multi-decades old platform into a future-ready asset capable of delivering safe and efficient production for decades to come.

Many projects are in the pipeline for slipover jacket proposals including the Marjan Gas Lift Project where eleven platforms will be upgraded with a new jacket following the slipover installation methodology.

About the Author

Muath S. Al-Turaif

Project Engineer, Marjan Gas Lift Package-2 Project, Marjan Gas Lift Division, Saudi Aramco

Muath S. Al-Turaif is a Project Engineer at Saudi Aramco and a certified Project and Risk Management Professional with more than nine years of technical and management experience spanning Saudi Aramco, major corporations and government organization.

Rameshkumar Kutti Ekanathan

Rameshkumar Kutti Ekanathan is an Offshore Civil & Structural Engineer and Project Management Consultant with more than 20 years of experience spanning from project proposal, detailed design, fabrication and installation of fixed offshore facilities for major oil and gas projects, currently working with Aramco Overseas Company.