Editor's note: This story first appeared in the November-December 2022 issue of Offshore magazine's first annual Offshore Oil and Gas Executive Perspectives Special Report.

By Wallace Pescarini, SLB

Much of the world’s traditional energy reserves are offshore—including 70% of conventional discoveries in the last 10 years. Developing them at a competitive cost and low-carbon intensity per barrel will play a key role in addressing the world’s energy trilemma, which requires balancing energy access and affordability with climate targets.

Over the years, technology innovation has enabled numerous gains in efficiency and footprint reduction for offshore exploration and development. The adoption of new technologies is crucial to keep the industry on this trajectory. Today, as conventional hydraulic or electro-hydraulic technologies reach technical and practical limits, new possibilities are opening up with all-electric technologies.

Electrification of the entire production chain (wells, subsea and topside) is a major technology leap that is now coming to maturity. It will help the industry do new things that cannot be achieved with hydraulic systems, further improving offshore performance while continuing to reduce total costs and carbon impact.

What electrification enables

Electrification of production systems eliminates all hydraulic infrastructures, at topside, seabed and wells.

At well level, many downhole flow control valves can be added on a single electric cable, with very precise bi-directional control and fully embedded monitoring to increase the reservoir drainage from each well—something not possible with hydraulic technology.

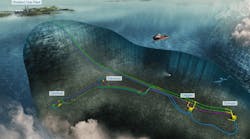

At seabed, electrification of infrastructure provides considerable simplification of the umbilical, elimination of hydraulic pressure units on topside, seabed distribution system and removal of kilometers of controls lines.

At topside, removing hydraulic equipment enables building simpler and lighter platforms and provides natural enablement to platform electrification, remote operations and unmanned facilities.

Lower carbon, higher value

The immediate value is a significant reduction of total costs from eliminating hydraulic infrastructure and its associated operating costs.

Electrification provides higher returns by enabling simultaneous production from multiple reservoir compartments in a single well. Adding more producing zones per well offers the opportunity to reduce well count. This eliminates well construction costs and minimizes footprint. To put this into context, the carbon footprint of drilling a deepwater well from a drillship on a 30-day campaign is about 5,000 metric tons of CO2.

Higher returns are also achieved with increased productivity from each well, thanks to precise control of commingled production from multiple reservoir zones. Among other things, this helps contain water production. With electric downhole flow control valves, each zone can be precisely choked back to leave the water in the reservoir, not only saving on the lifting costs to surface but also the energy for processing water at topside as well as reinjection. These energy savings translate to CO2 savings.

Another value-add is that electric systems have more reach than hydraulic ones, enabling access to remote reservoirs on long subsea tiebacks connecting to existing hosts. Accessing long step-out reserves without adding a new host might not be technically feasible with conventional technology, meaning that these reserves would likely be left untapped.

All-electric systems

Digital applications will play a crucial role to leverage the full value of all-electric systems. All-electric systems come with numerous direct measurements, relating to the reservoir behavior or equipment performance. Digitalization enables integrating these measurements with reservoir and process workflows—delivering offshore operators real-time, in-context data insights. Full electrification and digitalization will enable automation capabilities across the infrastructure, which will further enhance workflows.

Several electrification projects have already been completed. Last year SLB installed an all-electric intelligent completion system for a Norwegian customer that enabled producing six independently controlled reservoir zones in a single wellbore—returning higher productivity while reducing well count.

All-electric offshore technologies will be key to the diverse energy ecosystem of the future, comprising multiple interconnected energy systems and decarbonization mechanisms, from CCUS to hydrogen and beyond. Continuous innovation from the energy industry will make this future possible.

About the author: Wallace Pescarini is SLB’s president for Offshore Atlantic, a role he has held since 2020.