Engineering safety in deepwater drilling: A review of pressure relief valve systems in offshore MPD

Key Highlights

- PRVs are essential safety devices in deepwater MPD, venting excess pressure to prevent equipment damage and wellbore instability.

- Proper sizing, configuration and testing of PRVs are critical to balancing overpressure relief and maintaining formation integrity.

- Industry standards like API 520 and ABS provide guidelines for PRV design, installation and redundancy to ensure system reliability.

- Discharge location and piping design significantly impact PRV effectiveness, safety and environmental considerations.

- Ongoing development, testing and personnel training are vital for optimizing PRV performance and enhancing offshore drilling safety.

By Nitin Kulkarni, Blade Energy Partners

Offshore drilling represents one of the most technically complex and safety-critical activities in the oil and gas industry. Deepwater operations, in particular, are exposed to high-pressure, high-temperature (HP/HT) environments and very narrow operating margins between pore pressure and fracture gradient. The consequences of equipment failure or uncontrolled influx can be catastrophic, as exemplified by the Deepwater Horizon disaster.

This underscores the need for innovative technologies and robust safety systems that allow operators to maintain control of wellbore pressures while maximizing drilling efficiency. Over the last decade, managed pressure drilling (MPD) has emerged as a core technique in meeting these challenges.

Managed pressure drilling in deep water

MPD provides operators with precise, real-time control of wellbore pressures by using a closed-loop system in which a rotating control device seals the annulus and surface backpressure is applied dynamically. This capability allows the drilling team to maintain constant bottomhole pressure and manage influxes or prevent losses proactively.

In deepwater settings, MPD plays a particularly important role because of the long marine risers and the complex interplay of hydrostatics, surface backpressure and formation pressures. However, the integration of MPD into offshore operations introduces added complexity, requiring specialized safeguards to prevent overpressure scenarios that may compromise well integrity or equipment ratings.

One such safeguard is the pressure relief valve (PRV), which acts as a critical line of defense against overpressurization of the riser, surface piping and other MPD system components. Without carefully engineered PRV systems, the benefits of MPD could be offset by heightened risk of equipment failure or formation damage during unexpected pressure surges.

Role of pressure relief valves in MPD systems

PRVs function by venting excess fluid when pressure exceeds a set threshold, thereby protecting both equipment and formations. While effective in relieving overpressure, PRV activation also reduces surface backpressure, which can lower bottomhole pressure and trigger a formation influx.

Conversely, a failure to activate could lead to fracture or catastrophic equipment failure. Thus, PRV configuration requires a delicate balance: it must relieve enough pressure to prevent equipment damage, while maintaining sufficient annular pressure to preserve wellbore stability.

Industry standards such as API 92M/API 92S, API 520 and ABS guidelines provide detailed requirements for PRV sizing, discharge capacity, redundancy and installation location. Key practices include locating PRVs upstream of choke manifolds, ensuring discharge lines are unobstructed and sizing relief devices to handle maximum pump output or well-specific conditions. Redundancy, such as backup PRVs with independent power supply and remote indications, is also emphasized to safeguard against control system failures.

Types of PRVs

There are three main categories of PRVs used in MPD:

- Mechanical PRVs use spring-loaded mechanisms to open once set pressures are exceeded. They are simple and reliable, though less flexible.

- Software-based PRVs integrate programmable setpoints, remote operation and hydraulic actuation. These offer precision, real-time monitoring and greater adaptability.

- Pressure Relief Chokes allow adjustable, graduated release of pressure, making them valuable in managing large or rapid influxes without destabilizing the wellbore.

Selecting the right PRV type and configuration depends heavily on well conditions, anticipated pressures and the broader MPD system design.

PRV design, sizing and discharge considerations

PRV performance is highly dependent on correct sizing and discharge system design. According to API 520, PRVs must be sized for flow capacity, mud weight and operational pressures. Example calculations in this article demonstrate how mud density and flow rate affect required discharge area, underscoring the importance of engineering validation.

Discharge piping introduces additional complexity. Undersized lines can cause frictional backpressure, reduce valve capacity and increasing risk of malfunction, while oversized lines may add unnecessary cost. Lines must also be rated to withstand maximum possible discharge pressures.

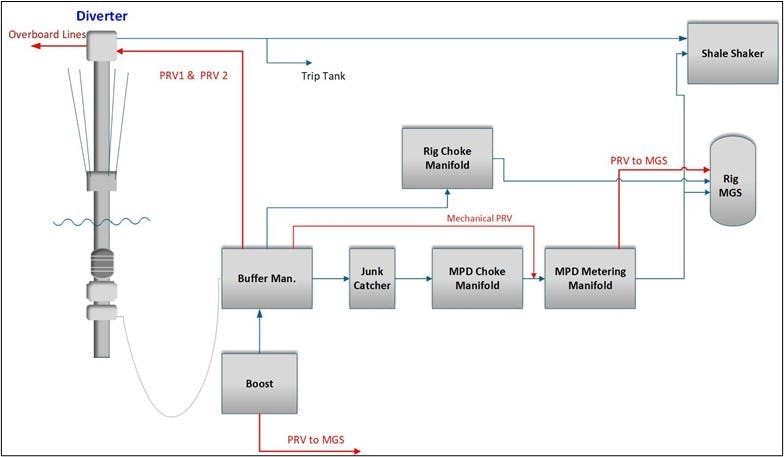

The choice of discharge location is a critical consideration. There are several alternatives, such as overboard lines, diverter tie-ins, shale shaker, discharge downstream of the choke manifold, trip tanks and mud gas separators.

Each method presents its own consideration of safety, environmental impact, cost and operational dependability. For instance, overboard lines offer secure venting away from the rig but come with high costs and environmental concerns; similarly, directing flow to the shaker house is more economical but increases the risk of hydrocarbon exposure to the crew.

There is no universal solution, and the discharge strategies should be guided by a thorough risk evaluation process considering the nature of fluids involved and the specific rig configuration.

Testing and reliability

There is a need for systematic PRV function testing, including setpoint validation and response time checks. Testing is typically carried out using cementing units, with activation pressures deliberately set lower than operational thresholds to confirm valve performance. Documented verification ensures compliance with API and ABS standards, while instilling confidence in system reliability during live operations.

Conclusions

PRVs are critical to safe deepwater MPD operations. Properly selected, sized and tested PRVs enhance well control, protect riser and surface equipment, and prevent catastrophic failure. However, their design must carefully balance safety with operational efficiency, given the dual risk of over-relief (can cause an influx) and under-relief (can lead to formation fracture or equipment failure).

As MPD adoption grows in deepwater drilling, continued refinement of PRV systems, improved response mechanisms and enhanced training for personnel will be essential. The development of robust PRV philosophies and adherence to industry standards can significantly reduce non-productive time and improve safety margins, ultimately contributing to safer and more efficient offshore drilling.

This article is based on the SPE paper “A Review of Pressure Relief Valve Systems Used in Deepwater MPD Operations” by Nitin Kulkarni et al., presented at the GOTECH Conference in Dubai in 2025. Access and download the full paper from OnePetro.

This article was edited for clarity and style by the Offshore editorial team.

About the Author

Nitin Kulkarni

Nitin Kulkarni is a project manager with Blade Energy Partners. He is a seasoned upstream oil and gas professional with more than 20 years of international experience, specializing in both managed pressure and conventional drilling, well engineering, and drilling-related service contract management. He has a bachelor's degree in instrumentation engineering from Savitribai Phule Pune University and a master's degree in petroleum engineering from Texas Tech University.