Offshore O&G industry increasing investment in well decommissioning

Key Highlights

- Decommissioning costs are rising globally, with significant investments directed toward well abandonment and environmental safety.

- Advanced tools and technologies are improving well integrity assessments and barrier placement as well as reducing operational trips, lowering costs and improving safety.

- Successful decommissioning requires strategic planning, integrated project management and collaboration between operators and service providers.

By Bart Joppe, Baker Hughes

The oil and gas industry is entering an era of increased decommissioning.

According to the “UKCS Decommissioning Cost and Performance Update” report, published by the North Sea Transition Authority in July 2025, operators spent a record US$3.24 billion in 2024 in the UK alone, and analysts at Rystad Energy project that the industry will spend $103 billion globally on decommissioning projects between 2025 and 2034. About 50% of that will go toward well abandonment.

This tremendous investment is occurring in an environment characterized by a heightened focus on carbon capture and increasingly stringent environmental regulatory requirements. Carrying out plugging and abandonment (P&A) activities in increasingly harsh conditions will be even more demanding, elevating well abandonment from a basic requirement to a strategic priority.

Challenges

To prevent unplanned hydrocarbon releases, sound P&A engineering must provide reliable solutions for frail and aging infrastructure in demanding operating conditions.

Effective abandonment begins with a thorough understanding of subsurface conditions. Geological and reservoir insights inform barrier placement strategies and help tailor abandonment plans to the unique characteristics of each well, which is essential for designing permanent barriers that prevent future fluid migration and environmental risk.

Understanding the well conditions introduces another set of challenges because even wells drilled in the same field at the same time age differently and present different downhole characteristics. Surveilling assets to understand the condition of the wellbore and understanding how the well was completed are vital to determining the proper abandonment solution.

The dual focus on the subsurface and the individual well architecture improves operational efficiency, de-risks operations and can reduce the surface footprint.

Advanced technologies at work

It is always important to meticulously review the well data to understand the design, age, depth and potential flow zones penetrated for each well. Engineers must then evaluate the surface conditions to observe casing vent flow or determine if there is sustained casing pressure.

It also is important to perform a field-wide subsurface evaluation to gather critical information about the capable caprock, which determines barrier placement location. Understanding the state of the annulus is critical because the barrier placement methodology is dependent on the annular condition. With this information, an informed decision can be made about the barrier material and barrier placement methodology so the barrier can be placed, verified for integrity and monitored to ensure the seal is reliable over time.

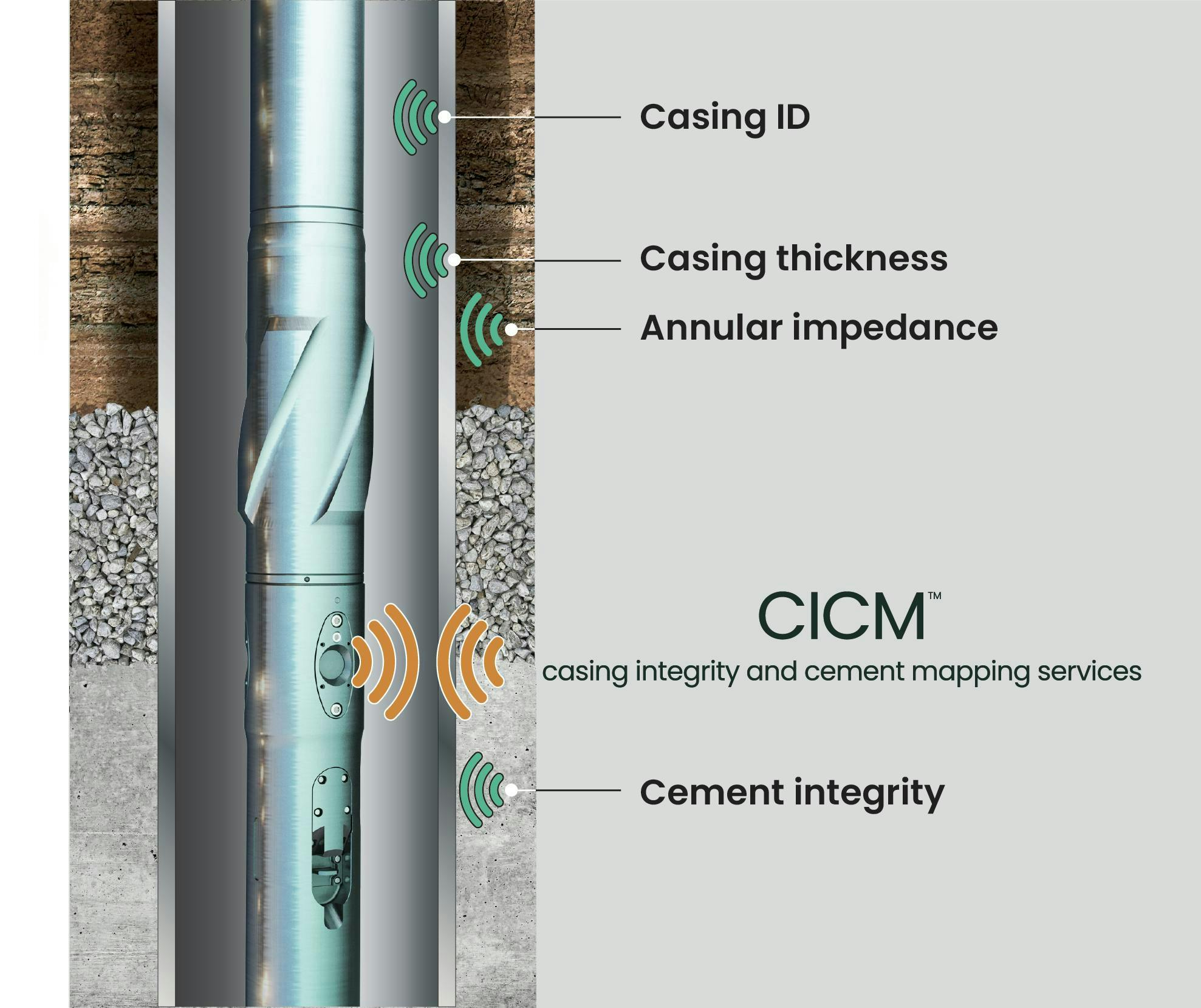

Historically, well integrity measurements have been obtained on wireline. Recently, however, a pipe-conveyed pulse echo ultrasonic tool for casing inspection and cement mapping has been developed that allows for combined runs in the well, rather than separate logging runs. The tool has acquired data during drilling, milling, cleanout runs and cementing operations, improving efficiency of rig operations and addressing challenges in highly deviated wells, while reducing the number of personnel on board.

When the casing annulus is uncemented, the well often can be plugged with a perforate, circulate and cement approach, using slickline, electric line, coiled tubing or jointed pipe to perforate or slot for annular communication. The selected barrier material is either pumped or injected.

In some instances, rig, hoists or hydraulic workover units are utilized to cut and pull casing to remove an annulus. Today’s modular cut-and-pull systems include hydromechanical slotting tools to aid in washing a barite-filled annulus and hydraulic pulling tools to aid in casing recovery while minimizing surface pulling capacity requirements. A recently introduced hydromechanical slotting tool provides an explosive-free solution that employs a reusable, single-bladed wheel that mechanically slots casing to create on average 1,500 slots per hour and can perform multiple operations in a single trip to deliver efficiencies while reducing risk exposure for offshore workers.

When a partially cemented annulus has mud channels, the typical solution is to perforate and squeeze, using a tool to perforate the annulus and then pump or place the barrier material and test its integrity. However, this method does not effectively seal micro-annuli, which frequently necessitates section milling—removing the casing locally and placing a cement barrier.

Traditional methods require metal cuttings (swarf) produced by section milling to be removed from the well, but an advanced solution eliminates swarf-to-surface through a unique upward milling process that deposits swarf deep in the rathole, enabling a secure rock-to-rock barrier placed against the caprock. This technology reduces section milling time by half, eliminates the need for milling fluid and significantly reduces the waste stream.

The deployment of these technologies discretely or combined as an integrated solution is decreasing trips in the well, thereby reducing time and total cost of operations.

Results from the field

An operator executing a P&A campaign in the North Sea was hindered by unknown annular conditions and wanted to perform a cement log behind 13 3/8-inch casing without pulling the entire 9 5/8-inch casing. A section was milled in the 9 5/8-inch casing, then a logging run across the exposed window was performed using the Casing Integrity and Cement Mapping (CICM) ultrasonic logging tool conveyed by drillpipe in combination with underreamers—for centralization and cleaning purposes—to get a clear picture of downhole conditions. This first-of-its-kind combination of technologies allowed the cement barrier outside the 13 3/8-inch casing to be logged and qualified without an additional wireline trip, which reduced time, costs, HSE risks and the number of workers required on site.

An operator in Canada was in a similar situation, lacking detailed downhole data on a well it wanted to P&A. The highly deviated well, 69-degree inclination had a previously cemented annulus that required remedial work because channels had formed in the cement barrier. The operator wanted to improve pressure/wash/cement operations by taking a different approach.

Real-time data from the CICM log made it possible to fully understand the annulus conditions and determine a remedial action plan. Based on the data, the operator identified a target area from 4,545 to 4,481 m and used the hydromechanical X-treme SJI (slot, jet and isolate) tool to create 3,328 slots in the casing and jet high-pressure fluid to clean out the annulus, making it possible to place a place a cement barrier using a pump-and-pull process, displacing a total of 55.9 barrels of cement.

The future of well abandonment

Technology is playing a transformative role across all phases of well abandonment, with innovations that continue to expand the toolkit for P&A, providing new solutions to tackle complex abandonment challenges with greater precision and reliability. And more improvements are on the way.

A service designed to deliver precise evaluations of multi-barrier zonal isolation soon will allow operators to significantly reduce costs and operational risks and improve efficiency across P&A workflows. For subsea applications, new systems deployed using smaller vessels reduce environmental impact and significantly reduce expenditures.

As important as these new technologies are, however, they are not in themselves the solution. Success requires comprehensive program implementation, and that necessitates strategic alignment coupled with integrated project management and the ability to evaluate and plan the entire well abandonment project.

This is why having a partner to coordinate subsurface analysis, engineering design, logistics, compliance and project execution is critical. Together, operators and oilfield services and equipment providers can select the best tools, tool combinations and optimal methodologies to consistently carry out safer, faster and more cost-effective well abandonment campaigns.

About the Author

Bart Joppe

Bart Joppe is the well abandonment leader for Baker Hughes' Mature Assets Solutions in Houston. In his 27 years with Baker Hughes, Joppe has performed operations, technical sales and business development roles in Europe, Middle East Asia-Pacific and the US. His technical expertise includes well intervention and abandonment. He also has been a project manager for new technology development.

Joppe graduated from the Institute for Petroleum and Gas Technology “Noorder Haaks” in Den Helder, The Netherlands, with a bachelor’s degree in drilling and production technology.