Technology applied for gas lift offshore Thailand

Zhiyue Xu

B. M. Richard

James H. Kritzler

Baker Hughes

The artificial lift method of gas lift is an increasingly popular means of boosting production from wells with lagging reservoir pressure. The method injects a compressed gas into well annulus between the production tubing and casing. Tubing and casing pressures cause the valve to open and close, which introduces the gas into the produced fluid in the tubing. The injected gas aerates the fluid to reduce its density, thus allowing the reservoir pressure to push the mixture of produced fluids and gas up to the surface.

Multiple gas lift valves are typically installed in a well to ensure optimal production as the well's pressures, fluid compositions, and productivity change. In a representative four-valve gas lift system, each gas lift valve is installed in a side packet mandrel (SPM), which in turn is placed on theproduction tubing of a gas lift well. Gas lift valves are designed for installation and removal by wireline while the mandrel remains in the well, which eliminates the need to pull the tubing to repair or replace the valve (as is required in a conventional gas lift mandrel).

After initial installation of a live gas lift valve system, pressurization is required to confirm the pressure integrity of the tubing or annulus, set a hydraulic packer, activate an isolation device or run cement through completion. Any unplanned pressure reversal or cement debris may damage the live gas lift valve, resulting in costly well completion failures.

Dummy valves are commonly deployed as a means of avoiding damage to a live valve. These higher pressure-rated dummy valves are loaded in the SPM to isolate the annulus from the tubing during initial pressurization or the cementing-through operation. Should the well then require gas lift to unload the completion fluid or to get the well flowing, the dummy valves must be replaced with the live gas lift string via a wireline intervention. Not only can an intervention be a time-consuming process that poses risks to the existing well infrastructure, but it also delays the onset of production. Slickline crews are a finite and in-demand resource, and sometimes cannot be scheduled for a valve change-out project for many weeks. Some industry estimates suggest that waiting up to one month for a valve change out on a 20-well platform translates to as much as 100,000 bbl in lost production.

A nanostructured solution

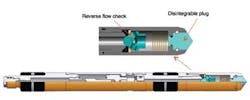

The industry need for lower risk, interventionless alternatives to gas lift valve changeouts prompted Baker Hughes to develop a smart gas lift valve that could function as a dummy valve during completion operations and then convert to a live valve, without the need for a well intervention. This is achieved through the use of a disintegrable barrier or plug made of nanostructured composite material. This plug provides the necessary annulus isolation while performing completions work, and then disintegrates in the presence of brine during the cleanup process, thus increasing completion operation efficiency of offshore wells. The nanostructured composite plug is rated for high pressures, chemically resistant to drilling mud, slightly reactive with fresh water, and disintegrates within 12 to 50 hours in salt water.

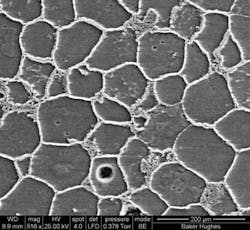

The smart material used to make the time-controlled barrier is a nanostructured powder metallurgy composite manufactured by consolidating reactive metal powders coated with metallic and/or ceramic reinforcements. Material composition and structure can be engineered at the micro- or nanoscale to vary the material strength and disintegration rate. The combination of high-strength and controllable disintegration rate is accomplished through engineered nanostructures between metallic grains. These grains become activation points for dissolution that can be triggered on demand. The nanostructures also act as strengtheners, which yield a composite material with high strength and toughness.

Typical concentrations of ions present in seawater, completion brines, formation fluids, or remediation acids, as well as typical downhole temperatures of 120°F (49°C) or higher, trigger a predictable and homogeneous dissolution of the nanostructured composite.

Displaying 1/2 Page 1,2Next>

View Article as Single page