Eldon Ball • Houston

Looking ahead about 10 years, oil and gas capex and “drilling intensity” must increase and new technology must be developed to meet future energy demand, according to Schlumberger Chairman and CEO Andrew Gould.

In remarks at the recent 39th annual Howard Weil Energy Conference held in New Orleans, Gould noted that “In the years following 2003, the thin margin of excess (production) capacity coupled with rapid price increases, led to the explosion in exploration and production capex from $130 billion in 2000 to $500 billion in 2008 – a compound growth rate of over 18%.”

All of this, he said, led to a period of frantic growth in activity that has had major effects on the industry structure.

“The first, and by far the most important effect was the re-emergence of resource nationalism,” Gould said. “This isn’t new, but in the 2000s resource nationalism was rife. Russia sought to capture a greater share of the rent.

“Venezuela closed again, and the Middle East did not open significantly. Mexico didn’t open at all. Libya opened but recent events have showed how transitory that was. Sanctions kept Iran and Sudan largely off limits. And after a spate of extraordinary discoveries, Brazil started to restrict access – not to investment but to foreign operators in the pre-salt domain.

The net result, Gould said, is that perhaps 75% of the world’s known conventional oil reserves are closed to international private capital today, while 60% of production originates from non-NOC operators.

This has resulted, he noted, particularly for the IOCs and independents, in opportunities offshore, in more remote and harsh environments, and at the heavier end of the hydrocarbon chain. In addition, discoveries of conventional oil accumulations became smaller, and therefore more difficult to produce economically.

“These sources of conventional oil production are increasingly complemented by unconventional oils, such as heavy or shale oils, which require massive projects of long duration that require huge amounts of capital,” Gould said. “As a result, if there is one common characteristic in the oil exploration and development projects to be executed in the future, both for deep offshore and complex unconventional oils, it is that they will become more difficult and more expensive to execute.”

Gould noted that there are now over 200 exploration and production projects worldwide that have a budget in excess of $1 billion. In addition, he said, “it is extraordinary that NOCs and independents now represent over 80% of total industry capex spend. No less than 30 oil and gas companies have annual capex budgets in excess of $4 billion—up from only 10 in 2001.

“While not wishing to embarrass any of my customers,” he said, “I would add that many greenfield projects suffer significant cost overruns. Indeed, as a general rule 30% of such projects experience budget overruns of 50%.”

In comparing Schlumberger’s Top 30 customers in 2010 to those of 2002, Gould said “the shift in revenue between customer groups is extraordinary. In 2002, the super majors represented 33% of the Top 30. This had declined to 22% by 2010. In the same period revenues from the NOCs almost doubled, while independents declined slightly.”

It is essential that technology not only address the challenges of exploration and increased drilling intensity but also the challenges of a changing customer base, larger projects, more remote operations, increasingly complex geological settings, and higher pressures and temperatures, Gould said. “It must also respond to new deepwater requirements post Macondo and help mitigate higher operating costs, particularly offshore.”

For some time we have stressed that maintaining production and bringing new reserves on line would require an increase in drilling intensity. The emphasis is not just on the number of wells to be drilled, but also on their increasing complexity and cost be it for expensive deepwater wells or for the technology required to make unconventional hydrocarbons economic through the introduction of practices such as factory drilling.

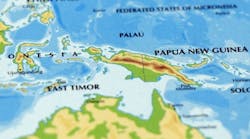

Exploration will be a key driver over the near term, Gould said. “The availability of deepwater rigs will accelerate this as more deepwater provinces become active. We have recently signed an exploration contract for an ultra deepwater rig that will drill successively in Australia, East Timor, India, Indonesia, and Mozambique.”

Macondo BOP report

“Forces from the flow of the well induced a buckling condition on the portion of drill pipe between the Upper Annular and Upper VBRs (variable bore rams). The drill pipe deflected until it contacted the wellbore just above the BSRs (blind shear rams). This condition would have most likely occurred from the moment the well began flowing and would have remained until either the end conditions changed (change in Upper Annular or Upper VBR state) or the deflected drill pipe was physically altered (sheared).

“The portion of the drill pipe located between the shearing blade surfaces of the BSRs was off center and held in this position by buckling forces. As the BSRs were closed, the drill pipe was positioned such that the outside corner of the upper BSR blade contacted the drill pipe slightly off center of the drill pipe cross section. A portion of the pipe cross section was outside of the intended BSR shearing surfaces and would not have sheared as intended. As the BSRs closed, a portion of the drill pipe cross section became trapped between the ram block faces, preventing the blocks from fully closing and sealing. Since the deflection of the drill pipe occurred from the moment the well began flowing, trapping of the drill pipe would have occurred regardless of which means initiated the closure of the BSRs.”

That in a nutshell summarizes the findings of the 551-page report for BOEMRE by DNV on “Forensic Examination ofDeepwater Horizon Blowout Preventer.” The report includes recommendations for further study, including:

- Elastic buckling -- The elastic buckling of the drill pipe was a direct factor that prevented the BSRs from closing and sealing the well. It is recommended the industry examine and study the potential conditions that could arise in the event of the loss of well control and the effects those conditions would have on the state of any tubulars that might be present in the wellbore.

- Shear blade surfaces of shear rams -- It is recommended the industry examine and study the ability of the shear rams to complete their intended function of completely cutting tubulars regardless of their position within the wellbore, and sealing the well. The findings of these studies should be considered and addressed in the design of future blowout preventers and the need for modifying current blowout preventers to address these findings.

- Well control procedures or practices -- The timing and sequence of closing of the UA and upper VBRs contributed to the drill pipe segment buckling and bowing between the two moving the drill pipe off center. It is recommended the industry examine and study the potential effects or results that undertaking certain well control activities (e.g. closing of the annulars or closing of the VBRs) could have on the BOP stack. Examination and study should identify conditions, which could adversely affect the ability to regain control of the well (e.g. elastic buckling of tubulars). Industry practices, procedures, and training should be reviewed and revised, as necessary, to address the prevention of these conditions.

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com