Gene Kliewer • Houston

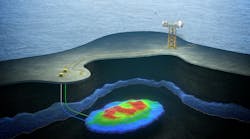

A record for distance, voltage, and frequency will be set when ABB provides to Aker Solutions drives and transformers for the subsea power distribution system at Statoil's Åsgard oil and gas field. Åsgard is in the Haltenbanken in water depths of 240-310 m (787-1,017 ft). Gas and condensate from the Midgard and Mikkel reservoirs are transported through long distance flowlines to the Åsgard B platform.

Aker has contracted ABB for $36 million to power the world's first subsea gas compression system from the Åsgard FSO offshore Norway. The system will be able to send 15 megavolt-amperes and 189 hertz over 43 km (26¾ mi). That will set a record for distance, voltage, and frequency between a drive on a floating production facility and seabed compressor, says ABB.

Aker Solutions has contracted MAN Diesel & Turbo Schweiz to supply four compressor units for Statoil Åsgard subsea compression project in the Norwegian Sea.

ABB and Aker Solutions combined on a similar project to power a subsea water injection system in Statoil's Tyrihans field, 31 km (19¼ mi) from the surface operating platform.

Åsgard umbilicals

Nexans has been awarded a €75 million ($102 million) contract by Statoil to design, manufacture and supply a total of 165 km (102½ mi) of static and dynamic power umbilical and power cables, as well as necessary accessories, for Åsgard.

Nexans's manufacturing facilities in Norway, Halden, Rognan and Namsos, as well as Charleroi in Belgium, will be involved in the project. Nexans will supply four lengths of power cable and power umbilical, each 40 km (24.8 mi) long, two lengths of dynamic power umbilical, and 2.3 km (1.4 mi) of standard service umbilical cable.

Aker to supply more subsea systems

Lundin Norway has awarded Aker Subsea a NOK-700 million ($123.9-million) EPC contract for a subsea production system for the Brynhild project in the Norwegian North Sea. The scope of work includes one template-manifold structure, one riser base, three subsea trees, three wellhead systems, a control system, a tie-in system, 38 km (23.6 mi) of umbilicals, an HP riser, and rental tooling.

There are also options for additional equipment, including other field developments.

Brynhild is northwest of the Ula field and 38 km (24 mi) east of the Pierce in UK waters of 80 m (262 ft). It will be developed as a fasttrack subsea tieback to the Pierce FPSO.

Engineering and procurement of the subsea production system will be conducted mainly at Aker Solutions' headquarters in Oslo. Fabrication of the subsea trees will be completed at Aker Solutions' manufacturing center in Tranby, Norway, while the company's yard in Egersund will handle the template-manifolds. The umbilical will be manufactured in Moss, Norway, and the control and wellhead systems in Aberdeen, UK. Aker Solution's service base in Aagotnes, Norway, will handle the installations, with final deliveries scheduled for spring 2013.

BP awards GoM subsea work to EMAS

BP Exploration & Production, Inc. has awarded Ezra Holdings Ltd subsea construction division, EMAS AMC, a contract for subsea work at Atlantis in Green Canyon block 743 in the GoM.

The project scope is installation and replacement of subsea equipment comprised of manifolds, pipeline end manifolds (PLEMs), jumpers, and associated hardware in 6,800 ft (2,073 m) of water, as well as assisting BP to commission and start-up of the equipment.

Atlantis is the world's deepest moored floating production facility and can process 200,000 b/d of oil and 180 MMcf/d of gas.

Noble calls for subsea trees on Tamar in the eastern Mediterranean

Noble Energy has awarded Delmar Systems Inc. a contract to install five subsea trees in the Tamar gas field offshore Israel in the Mediterranean Sea.

Delmar says it will use the Heave Compensated Landing System to install the equipment on the Matan block in 5,500 ft (1,676 m) water depth working with the TransoceanSedco Express semisubmersible rig. Project commissioning is expected in late 2012.

Launching a Saab Seaeye Panther ROV on location. Cal Dive International (Australia) Pty Ltd has bought a Saab Seaeye Panther XT Plus ROV configured for hazardous-area operations. The ROV configuration chosen by Cal Dive, includes a Seaeye wide-angle low-light black and white camera and a Kongsberg compact color zoom camera. It also has a Tritech Super SeaKing sonar with dual frequency sonar head, and a Tritech altimeter with auto altitude option. Fitted to the ROV are two Schilling Orion manipulators: starboard side, a seven function position feedback manipulator with 3.8-in. gripper, and port side, a four function rate manipulator with 7.8-in. gripper. For debris clearance, the Panther comes with a rotary disc cutter and a 38 mm anvil cutter. There is also a water jetting system, a cleaning brush assembly and manipulator-held cleaning brush tool. A Cygnus ultrasonic thickness gauge comes with the ROV, together with a CP proximity probe to check anode protection.

In addition, Cal Dive has won a contract to install an 8-in subsea pipeline in Abkatun field, Gulf of Mexico, for Pemex Exploración y Producción. The $27-million project, scheduled to begin in April 2012, will be in 47 m (154 ft) water depth.

ROV spending to reach $1.7 billion in 2015

Total annual expenditure on ROV support of underwater operations is expected to grow from $891 million in 2010 to $1,692 million in 2015, predicts Douglas-Westwood in its World ROV Market Forecast 2011-2015.

The world fleet of work-class ROVs consists of 641 units operated by 21 companies.

"Although ROVs are today used in many sectors ranging from academic research to military applications and salvage, the largest commercial user is the offshore oil and gas industry where they have become an essential tool for deepwater operations," said John Westwood, Douglas-Westwood chairman. "This was clearly demonstrated recently in the subsea work to cap the Macondo blow-out in the US Gulf of Mexico."

Offshore Articles Archives

View Oil and Gas Articles on PennEnergy.com