By Theo Mayer,Panaoram Technologies Inc.

Nearly all producers in the oil and gas industry are considering an invest-ment in large-scale visualization, a technology that has had profound effects on upstream development and existing field production for the major oil companies.

The financial and human resource commitment to a visualization methodology is substantial; however, the returns on the investment are dramatic. The benefits are distinct, large, and obvious enough to drive well over 100 facilities into existence since the beginning of 1998.

It is no longer an experiment but rather an accepted competitive edge that everyone in the industry must evaluate.

Business case

The evaluation begins with a keen examination of the business case. Fortunately, the "value testing" for this powerful combination of computing, software, and display technologies has been well established among the majors. Some companies are deploying entire networks of facilities.

Today, the industry experience, expertise, and success stories are plentiful. For the majors, a return-on-investment in a facility has been as fast as one operating quarter, but typically it is agreed to be less than a year. It is reasonable to expect a large-scale visualization capability to reduce project costs and/or field errors by 5-10%. The software providers are often good reference sources to start with, but it is from the actual practitioners, users of the technology, that the most direct insights are gained.

Components and value

The next step is to get an overview of the requisite components and the value proposition each brings to the endeavor. Large-scale visualization is comprised of three intertwined technologies: software, computing hardware, and the visual facility.

It starts with application software that is capable of manipulating the industry's vast databases into meaningful 3D and stereoscopic visuals. The greatest benefits come from the ability to run these visual interpretations in real-time. The software allows one to explore and postulate dozens of ideas and scenarios in minutes. This is an activity that would have taken weeks, or perhaps months using traditional methods.

The computer hardware needs to have the power to manipulate these databases and the computers need to be fast enough so that the user's exploration is not hampered by the hardware. Without the performance, many issues just aren't worth exploring. Of course it is crucial that the computer platform not only have the performance, but that also is fully compatible with the software. Finally, the computer needs to be configurable to display on large screen visualization display systems.

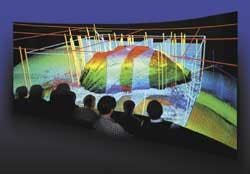

The visualization facility itself with its group virtual reality (GVR) visual environment is designed to promote interaction and collaboration. It is the existence of this facility that gets a team out from behind the desks and engenders the collaboration process.

This is the most valuable aspect of large-scale visualization. Team members provide the insight of their discipline to the decision making process – interactively and in real time. In this environment, the geologist, geophysicist, hydrologist, petrophysicist, pipeline engineer, drilling engineer, project manager, and others interact against the data. All the issues and alternatives are explored.

The work product of the GVR environment is increased insight, collaboration, and better, faster, more accurate decisions. It is a combination of technology and social interaction to solve and resolve complex decisions.

Options

The next step is gathering information and evaluating the options. Most companies have software experts in house. These experts can contact the visualization software providers to evaluate the software options.

Most companies also have in-house computer expertise via their information technology team. Once again, these individuals can make it possible to fast-track the exploration of suitable platforms. Real-time visualization tasks require specialized hardware.

That leaves one "mystery piece" to the evaluation puzzle, which no one in an organization is likely to have much experience with – the integration of the technologies into a GVR environment.

GVR environments go by many names: HIVE, Reality Center, Visionarium, Decision-arium, Holodeck, TerraDeck, CAVY, and iCenters to name a few. From a technical perspective, the facility is a super-resolution (2.5-4 Megapixels), 3D, stereoscopic display environment that accommodates 3-20 people. It is big enough for a group to work together and often consists of multiple projectors, seamlessly stitched together into a single composite image.

The most popular type of system in the oil and gas industry is the curved screen solution. The system is typically three projectors seamlessly arrayed onto a cylinder type screen. The second type is the flat screen. Again, it is typically two or three projectors seamlessly arrayed onto either a front projection or a rear projection screen.

Curved Screen

A curved screen can put more screen surface into a smaller space. Perhaps the most important benefit is the reduced fatigue factor. As the group views the data from a central location, the viewer's focal distance to the screen is generally maintained. If the same size screen is laid out flat, the ends are much further away from the viewer. During a long work session, this constant refocusing is tiring and can impair the team's concentration.

Many engineering-oriented visualization facilities use a flat screen. This is because they are typically reviewing CAD design data with their insight coming from seeing 3D, stereoscopic objects to scale. These objects are more easily understood from a flat plane. For most oil and gas applications, the users are immersing themselves in more abstract data where concentration and interpretation are core skills.

A typical curved screen is long and skinny with the image more than three times wider than it is tall. When flat screens are used, it is often a good idea to square this up a bit with an aspect ratio closer to twice as wide as tall.

Flat screen

On a flat screen, the viewer also has the choice of front or rear projection. There are advantages to both choices. The preferred system is typically rear projected. This moves all the heat and noise of projectors into another room and allows the viewer to walk right up to the screen without blocking the projected image. It makes for an exciting presentation environment with the ability to parade in front of a 20-30 ft wide screen.

The disadvantage of rear projection is that the company must give up facility space for photons. Typically a 9-12 ft deep area is required. The light path is folded using front surface mirrors to keep the rear projection space to a minimum. This back room often doubles as the equipment and computer room, putting all the hot, noisy, and heavy electric consuming gear into one space.

It is technically possible to have a curved, rear-projected system, but this is generally impractical. The projector light path must "porcupine" outward, taking up vast space. It can be done, but requires a warehouse of space.

Cubes

Another format that has found some application in oil and gas is the virtual reality cube. There are several brandings for this technology including CAVE™, I-Space, and HoloSpace. In these environments, the team stands inside a cube that has three to six sides filled with projections. The viewers wear stereoscopic goggles and a device known as a "head tracker." With this equipment, the viewers are fully immersed in a near holographic environment. With the head tracking, the 3D objects realistically change perspective as the viewer physically changes his position relative to the projection.

This technology fails to meet some of the core criteria for large-scale oil and gas visualization. These systems take up a huge amount of room, and they are not well suited as collaborative environments. Only one person can wear the head tracker. Every one else standing in the cube is a passive participant with a potentially strange view of the data.

Because these cubes are typically four to six channel systems, they require expanded computer and projection resources. This makes them an extremely expensive resource aimed at a limited audience.

Also a consideration is that the viewer physically stands in these environments. Though they are impressive during demonstrations and presentations, they are exhausting places to work for extended periods.

Resource allocations

What are the general requirements in physical space, budget and staff? The ideal space is 40-ft by 50-ft by 15-ft to accommodate work groups of 10-15 as well as full presentation capabilities for 30-40 people.

Most often, the visualization facilities are fit into existing buildings with standard 9-ft drop ceilings. The room allocations tend to range from 30-ft by 30-ft and up. This is adequate for front, rear, curved, or flat systems.

For those with space restrictions, WorkGroup systems provide nearly all the benefits of the large-scale systems, but are smaller, totally free standing, and require no facility modifications. They can serve as an entry point for organizations that are not ready to commit the physical space or may be considering a single facility to be reallocated to other asset teams on a rotational basis. These systems can be fit into facilities with standard height ceilings and into rooms as small as 15-ft by 15-ft.

To help work through this, visualization system integrators will visit a site and help the clients work through the physical space issues considering HV/AC, electrical, lighting, room layout, room treatment, acoustics, and space planning. The integrator will then work with a company's facilities people to do a final design and draw up plans.

Cost

The cost of a facility is highly variable. A full facility will typically cost $600,000 to $900,000, including hardware, facility modifications, furnishing, lighting, etc. Fully functional facilities can be put in place for as little as $350,000. This means a monthly cost between $5,000 and $15,000 including maintenance.

A simplified facility can be had for under $150,000. This would include a collaborative, 3D, stereoscopic, high brightness projection facility. The main restrictions are image size, resolution, maximum data size, and performance.

The most basic entry point is a desktop visualization capability. An example is a Panoram PV Series display combined with a Sunblade 1000 computer fitted with three Expert 3D-Lite Cards. This type of package is under $50,000 and although not stereoscopic, still provides 3.8 million pixels resolution, on a wide format screen, with a mini collaborative environment for 2-3 people.

Staffing is another cost consideration. Some organizations dedicate a full-time employee to the facility.

Summary

Large-scale visualization is a proven tool for upstream development, planning, and field operations in the oil/gas industry. One can make a solid business case for getting into the technology with a reasonable expectation of a return on investment in one to four operating quarters. There are several facility types, computer platforms, and software choices that need to be sorted based on budget, legacy infrastructure, and project scale. The investment to get into the technology will range from an entry-level lease cost of $800 per month to $15,000 per month for a full-blown facility.

Author

Theo Mayer is the President and CEO of Panoram Technologies, a leading provider of visualization facilities. He can be reached at Tel: 818-504-0714, Fax: 818-504-0636, or E-mail: [email protected].