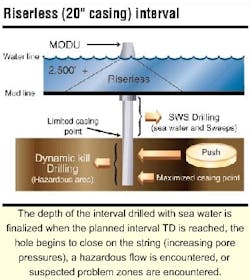

As drilling activity explores deeper waters, new technology and methods are required. Riserless drilling techniques such as Baker Hughes Dynamic Kill Drilling system) can place the shoe of the surface casing where it is most beneficial to the success of deepwater wells in the Gulf of Mexico. Conventional seawater sweeps (SWS) and calcium chloride drilling often have to settle for a less desirable, shallower shoe placement and the resulting weaker formation integrity test (FIT).

Under the traditional SWS method of drilling, the surface hole and setting the surface casing (usually 20 in. or 22 in.), limitations must be considered. After jetting 30 in. or 36 in. pipe to approximately 300 ft below the mudline, drilling of the next interval begins with a 24 in. or 26 in. drilling assembly. The fluid used to drill this interval to total depth (TD) is seawater, supplemented with 100-150 bbl of viscous bentonite sweeps at each connection. This assists in proper hole cleaning.

Using the SWS method, it is necessary to have kill fluid on hand at all times. If pad fluid is desired, it is either stored alongside the kill fluid, or blended from the base kill fluid, once TD is reached. At interval TD, the pad mud is spotted and the surface pipe is run and cemented. The depth of the interval drilled with seawater is finalized when the planned interval TD is reached, the hole begins to close on the string (increasing pore pressures), a hazardous flow is encountered, or suspected problem zones are encountered.

The benefits of using seawater in the SWS method are obvious. Seawater is readily available at the location and it is quite inexpensive as well. However, challenges inherent with SWS drilling alone are a consideration when time and money are factored into the equation, especially when a deeper well profile is targeted.

Potential limitations of SWS are:

- Massive erosion to the wellbore, resulting in poor hole stability/integrity

- Possible erosion of the 30 in./36 in. shoe

- Poor hole cleaning

- Weight-up and rheological limitations

- Shallow gas/water flows

- Hole closure due to formation pressure

- Difficulty in placing the 20 in. casing on bottom

- Potential shoe squeeze kill and pad fluid storage requirements

- Poor leak-off test (LOT) and FIT.

SWS often requires shallower-than-desired placement of the casing shoe for the next interval. This may cause a slimmer than desired completion string. In severe cases, the ultimate TD of the well may be obviated.

SWS drilling is the most economical and practical means of drilling the surface interval, if shallow flows and lower FITs are not critical. However, when conditions dictate a more stringent approach, an advanced technology such as dynamic kill drilling (DKD) may improve results.

Calcium chloride drilling

The 20 in. surface interval may use calcium chloride supplemented with viscous sweeps at each connection as a drilling fluid. The main benefit of calcium chloride drilling is that the compound may be stored in the large brine tanks on mobile offshore drilling units (MODU). Some of these tanks hold as much as 20,000 bbl of brine. When logistics, such as rough seas or remote locations, are problematic, it is feasible to utilize calcium chloride (if storing large quantities is permissible).

Treating the fluid so that it has acceptable rheological and fluid loss properties is tremendously expensive and is often a temporary process as well. When fluid weight is an issue, drilling with calcium chloride is not the preferred method since its ability to be weighted up inexpensively is limited. This technique does offer advantages over the standard SWS method, since calcium chloride fluid is a highly inhibitive drilling fluid base, storable in the large capacity brine tanks available on many MODUs, and requiring no agitation.

Calcium chloride can be loaded at the docks, eliminating boat delivery to the site. Fewer boats or no boats at all will be needed during the actual riserless drilling operation. However, in the event that calcium chloride must be ferried to the rig location, a small armada of ships will be required. Limitations may rule out this method when operational issues are considered:

Examples of use

To use 15,000 bbl of 11.0 ppg calcium chloride cut back with seawater from 11.6 ppg would require 80.3% calcium chloride and 19.7% seawater. At a retail cost of $18.74/bbl, the task requires 12,045 bbl of calcium chloride and 2,955 bbl of seawater. The calcium chloride cost is $225,723.30. Viscosifiers and/or fluid loss agents for the fluid are quite expensive and would elevate the costs even more.

To use 15,000 bbl of 11.0-ppg whole mud using the DKD system, 5,000 bbl of 16.0 ppg base DKD fluid is blended with 10,000 bbl of seawater (1:2 blend). No viscosifiers are required except for sweep purposes. The cost of the DKD fluid at a retail cost of $32/bbl is $160,000.00.

The calcium chloride method is more expensive than the DKD solution and does not provide wellbore stability and integrity, although it is a highly inhibitive fluid.

DKD drilling of the surface interval allows deeper shoe placement and the option to drill safely through shallow hazards while maintaining the stability/integrity of the wellbore. The section of the interval employs blended whole mud to achieve these objectives and pushing the shoe of the surface string to its maximum potential depth. This operation is usually performed with an annular pressure monitor in the hole.

The services have been performed for operators in the Gulf of Mexico since 1997, and picks up where conventional SWS drilling lacks in performance, depth, and economy. This is a safe method for drilling the troublesome zones beyond the limits of SWS drilling. Once a maximum but safe limit has been reached with SWS drilling, the remaining portion of the surface interval is drilled using 16.0 ppg base fluid blended with seawater.

The fluid is specially formulated to provide yield points of 9 cps to 16 cps, when cut back to 11.0 ppg with seawater. This is a cut back of 2 bbl of seawater to 1 bbl of base fluid. This method of blending the fluid with seawater or pad fluid, while drilling with mud weights from 8.55 ppg to 16.0 ppg, results in:

- Reduced logistics for storage of kill/pad fluid

- Reduced deckload

- Elimination of squeeze jobs

- Reduced logistics for transportation

- Hole stability/integrity ensures optimum setting for placing 20 in. casing on bottom on the first attempt and is the optimum scenario for a successful cement job on the first attempt

- Safe drilling through shallow gas/water flows

- Elimination of unnecessary pipe strings such as a scab liner

- Pushes the shoe of the 20 in. casing well beyond the limitations of conventional SWS methods

- Extended subsequent casing points

- Achieves FITs that are greater than those available through conventional SWS drilling, thus enabling greater penetration for the next casing run and ensuring success of the deeper well profile.

Using available data, specialists work with the operator's engineer in charge of the project to determine pore/frac pressures and troublesome areas in the surface interval. Once these areas have been determined, proprietary software is used to develop the mud weight schedule and determine the mud volumes required, minimum flow rates required, and maximum rate of penetration (ROP) allowable.

These units are configured to operate with SWS, calcium chloride, or whole mud applications. Connections to rig equipment and internal hydraulics use 4 in. quick-disconnect tank hoses and cam locks. The base fluids are routed through two or more flow-tube assemblies (FTA), into the Inteq mixing manifold (IMM), and out to the active system of the rig.

Accurate open-throated flow tubes for fluid measurement are used. They provide flow data using magnetic flux lines, sending signals to digital meters that calculate flow rates accurately. Since the flow tubes have no internal turbines, they are virtually impervious to plugging problems or mechanical failure during use. The IMM is a shearing device as well as a blending unit. As the assigned operator follows the weight-up schedule while drilling the surface interval, mud weights are achieved (within a tenth of a ppg) by adjusting the throttle valve. The results are displayed in gallons per minute (gpm) on the digital readout meter. The 4-in. unit can blend 11.0 ppg mud at a flow rate of 1,950 gpm. The 6 in. units can blend the same fluid at a flow rate of 3,750 gpm. Unit rig-up takes approximately 4-6 hours.

More than 15 dynamic kill drilling jobs in water as deep as 8,875 ft (a record) have been performed for operators in the Gulf of Mexico. No shoe after these operations has ever had to be squeezed after the cement job. No severe problems have been experienced while placing the surface pipe on bottom. No incidents of bit balling have been noted when maximum ROP allowable, minimum flow rates and mud weight schedules are adhered to.

The process has experienced no significant problems running 20 in./22 in./26 in. casing to bottom, when parameters are followed. Volumes and weight calculations using prudent drilling practice have proved to be extremely accurate. This advanced riserless drilling technology has been the service of choice on four jobs that had been under fluids contract to other operators.

With an average water depth of 4,150 ft and an average "push" of 1,160 ft over the last several years, the average volume of base fluid per job is approximately 12,500 bbl. Savings to the operator may be realized in the reduction of non-productive rig time, elimination of casing strings, deeper casing points for the strings following the surface pipe, reduction of total days, and a reduction in logistics requirements for fluid transportation and storage.

Using available data, specialists work with the operator's engineer in charge of the project to determine pore/frac pressures and troublesome areas in the surface interval. Once these areas have been determined, proprietary software is used to develop the mud weight schedule and determine the mud volumes required, minimum flow rates required, and maximum rate of penetration (ROP) allowable.

These units are configured to operate with SWS, calcium chloride, or whole mud applications. Connections to rig equipment and internal hydraulics use 4 in. quick-disconnect tank hoses and cam locks. The base fluids are routed through two or more flow-tube assemblies (FTA), into the Inteq mixing manifold (IMM), and out to the active system of the rig.

Accurate open-throated flow tubes for fluid measurement are used. They provide flow data using magnetic flux lines, sending signals to digital meters that calculate flow rates accurately. Since the flow tubes have no internal turbines, they are virtually impervious to plugging problems or mechanical failure during use. The IMM is a shearing device as well as a blending unit. As the assigned operator follows the weight-up schedule while drilling the surface interval, mud weights are achieved (within a tenth of a ppg) by adjusting the throttle valve. The results are displayed in gallons per minute (gpm) on the digital readout meter. The 4-in. unit can blend 11.0 ppg mud at a flow rate of 1,950 gpm. The 6 in. units can blend the same fluid at a flow rate of 3,750 gpm. Unit rig-up takes approximately 4-6 hours.

More than 15 dynamic kill drilling jobs in water as deep as 8,875 ft (a record) have been performed for operators in the Gulf of Mexico. No shoe after these operations has ever had to be squeezed after the cement job. No severe problems have been experienced while placing the surface pipe on bottom. No incidents of bit balling have been noted when maximum ROP allowable, minimum flow rates and mud weight schedules are adhered to.

The process has experienced no significant problems running 20 in./22 in./26 in. casing to bottom, when parameters are followed. Volumes and weight calculations using prudent drilling practice have proved to be extremely accurate. This advanced riserless drilling technology has been the service of choice on four jobs that had been under fluids contract to other operators.

With an average water depth of 4,150 ft and an average "push" of 1,160 ft over the last several years, the average volume of base fluid per job is approximately 12,500 bbl. Savings to the operator may be realized in the reduction of non-productive rig time, elimination of casing strings, deeper casing points for the strings following the surface pipe, reduction of total days, and a reduction in logistics requirements for fluid transportation and storage.