Paraffin removal technology not going away

William Furlow

Technology Editor

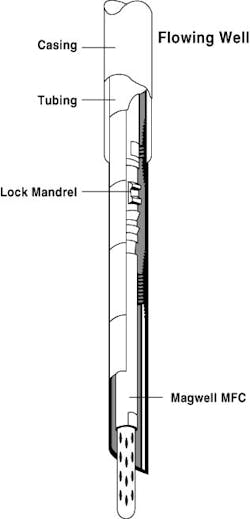

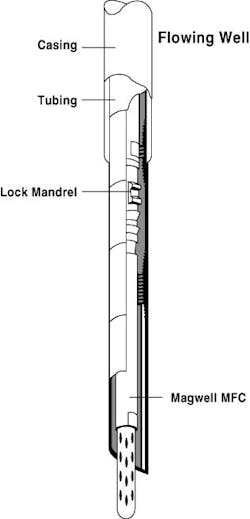

The Magnetic Fluid Conditioning tool is designed to work with existing paraffin control systems.Magnetic fluid conditioners are not going away. Though detractors still don't trust a technology they cannot readily evaluate or understand, case study anecdotes continue to accrue.

Paraffin problems are on the rise as pipelines are laid in deeper waters. The differential between the temperature of the oil and the cooler pipeline it is flowing through precipitates these sticky crystals. As the paraffin builds up inside the pipeline walls, it restricts and eventually blocks the flow.

The magnetic fluid conditioner (MFC) is a simple hydrodynamic generator. It requires no external power source to direct fluids through the magnetic fields generated by magnets. This MFC treatment alters the growth pattern of paraffins and scale crystals, which inhibits their clinging to pipeline walls. According to Mag-Well, which produces an MFC using proprietary technology, the magnetic fields interact with the charged crystal nuclei in the fluids, affecting precipitation. The electrical charges on the crystal nuclei and the growing crystallites are affected at the surface, altering the growth of the crystals in general and on specific planes.

Because the crystals grow differently in size, shape, rate, and number their solubility, or level of suspension in fluid, is altered. According to Mag-Well, this alteration is what dissolves the scaling and avoids the paraffin build-up.

Mag-Well claims the MFC lowers the cloud point of the fluids by as much as 60°F allowing the paraffin to remain in solution, when it otherwise would have deposited on the flowline walls.

Deepstar tests

In late 1996, Deepstar spent $135,000 to fund tests that looked into the feasibility and science of using magnets to prevent paraffin blockage. Basically the goal of this research was to determine if a magnet could be used to alter the cloud point of oil. Deepstar contracted with Dr. Sam Colgate of the University of Florida to conduct tests on a variety of oils.Colgate developed a testing apparatus that divided a stream of oil into two equal streams that were measured by sensitive flow meters. The two streams would be cooled equally until they reached the cloud point and paraffins developed. One of the streams would be treated with an MFC device; the other would not.

James Coleman, Principal Research Engineer with Arco, chairs Deepstar's Novel Technologies subcommittee. He said Colgate was nearing the end of the funding with no positive effects, when a commercial MFC vendor, Paramag, offered to provide its electromagnetic product for the study. After installing the Paramag device on his testing apparatus, Coleman said Colgate did produce results.

The stream treated with the magnet lowered the cloud point by 2°F. While this is still some distance from the 60°F touted by Mag-Well, it was a significant finding, Coleman said. This significance increased when Colgate was able to develop a permanent magnet that could reproduce these results.

Two separation degrees

In ultra deepwater fields 2°F is an insignificant figure. In the words of Coleman, "it amounts to paraffins developing another two feet down the flowline". In the lab, however, the 2°F change was significant. Colgate had made a breakthrough. Using laboratory test conditions he was able to show that MFCs do have an effect that is reproducible across a variety of oil types. Coleman said the study was about to move into field trials when the funding ran out.Currently, there are no plans for Deepstar, now in its fourth phase of development, to further fund this research. Coleman said Colgate may pursue other avenues of funding, but for the time being the testing apparatus that was developed through the funding seems to be Deepstar's biggest return on investment. Coleman said this tool is currently being installed on a field in West Texas for further tests.

While the funding may not be in place, the fact remains that the MFCs work in the lab. Coleman said if an MFC can consistently move a cloud point down two degrees, then the question is how does this work, and how can the effect be increased to a point where it would be a reliable alternative for controlling paraffins.

Mag-Well skeptical

Mark Varel, Vice-President with Mag-Well maintains that his product will never be the answer to paraffin problems. He said he is often frustrated by clients who install the MFC on the "flowline from hell." He said, in these cases, an operator assumes he has nothing to lose by trying the new technology in an extreme situation where other methods have failed. Varel said MFCs should not be thought of as a replacement for chemical and mechanical treatments already being used. If there is a pigging program in place, for example, then the pigging should continue. What an MFC will do is make such treatments more effective and reduce the frequency they are needed.According to Varel, the biggest problem MFC technology faces is overstating its applications. He describes the tool as a treatment, and emphasizes that it is only effective in certain circumstances. "MFC technology should be viewed as one more weapon in your complete arsenal of weapons for deposit control," he said.

Commenting on the Deepstar tests, Varel, who said he has samples in his lab in which MFC treatments have successfully lowered the cloud point by 60°F, sees the result as "just luck." Such an opinion may seem counter-intuitive for someone who makes a living selling the product, but Varel is adamant that the products used and the tests conducted were lucky in matching a fluid velocity with a gauss strength (the strength of the magnetic field). These factors, along with arranging the magnets in a circuit to guarantee all the fluids are exposed to a field of equal strength, are key to unlocking the technology's potential. Varel said he is frustrated by studies that do not acknowledge these criteria or seek input from the marketplace. He said the tuning of his products is tailored to specific applications.

There are three things that make this technology work, according to Varel: gauss strength, circuit design, and fluid velocity. These have to be in balance for the technology to be optimized. Varel said the tests in Florida worked, but did not show the full potential of MFCs because the three factors were not fully balanced.

"It's all about optimizations. It has nothing to do with any kind of finite result," he said. Varel said that he has been told by Deepstar that if the technology requires such fine tuning then the applications are not broad enough for it to be of interest.

Halliburton's view

In 1996, Halliburton entered in to an agreement with Mag-Well to market its downhole magnetic fluid conditioners. At the time, Mag-Well did not have any research data, only case history information to recommend its products. According to a paper prepared by William G.F. Ford, Ph.D., (TST-6813-96) Halliburton assembled a team of Halliburton and Mag-Well officials to devise a method for evaluating the product.The team devised a calcium sulfate scaling test. The test concluded that the tool prevented calcium sulfite from adhering to a heater element and forming large chunks of scaling that were present on a control heater element.

Though it produced brochures touting tools and technologies keyed to Mag-Well's system, Halliburton recently announced it is parting ways with Mag-Well effective later this year. This is a change for a company that has produced technical papers celebrating the tool's effectiveness in scaling removal and is listed as a technical contact on one of Mag-Well's case studies dated earlier this year.

Mark McCurley, with Halliburton, said this was a marketing decision and not based on the controversial MFC technology. McCurley said Halliburton has not met the expectations of its original agreement with Mag-Well, and under reassessment decided the tool was outside its core business. McCurley said this was an issue of focus and referred technology questions back to Mag-Well.

Varel said he was not phased by the Halliburton decision. He blamed it in part on internal politics at Halliburton but much of the marketing was still the responsibility of Mag-Well. After September the product will still be distributed by Halliburton in the countries where there is still demand. Halliburton will sell the product, but with the Mag-well name. "It has nothing to do with whether the technology works or does not work," Varel said.

Copyright 1998 Oil & Gas Journal. All Rights Reserved.