William Furlow

Houston

The semisubmersible Uncle John now carries a top drive modified with a collett system that allows rotation of the top drive 90! to grab pipe joints horizontally.

Mensa well never out of control

Reports of problems with one of the A1 subsea trees on the giant Mensa field in West Delta 143 of the Gulf of Mexico have been confirmed by Shell. The problem, which reportedly occurred on January 2, stemmed from a circumferential crack in the two-part christmas tree at the 4-in. Torus III connector, which joins the upper and lower blocks of the 10,000-psi tree.Reports differ on exactly what happened when the trees separated. One report stated the stab and hinge-over flowline jumper connection kept the tree from separating more than 10 cm before the BOP shut off flow. Shell said the subsea safety valve performed as designed and the well was quickly shut-in by the first stage of the two-stage tree.

"The well that experienced the crack shut down as it was supposed to shut down. All the valves associated with shutting off that well were located in the lower tree which was not damaged at all," a source with Shell said. The A3 well was also shut down, so Shell could replace the connector on that well, but the source said there was not a crack in that tree.

This subsea tree was specially designed to allow removal of the production block for maintenance, without killing the well. The semisubmersible George Richardson was pulled off spudding of the A-2 well nearby and moved onto A-1 where it pulled the upper tree using drill pipe. Shell said it was convenient to have this semisubmersible nearby, but pointed out that with the well safely shut in, the operator could have waited for another vessel to become available.

Shell confirmed that the tree was sent to FMC in Houston where it was examined by Shell and the MMS. MMS reports Shell estimated gas escaping totaled 20,000 cu meters through the crack before the subsurface safety value shut it in. Shell says there was no escape of liquids from the well. One report quoted a former FMC engineer as saying the prototype for this tree had problems withstanding cyclical bending moments caused by the flexible jumper, although that had not been confirmed. The jumper is attached to the upper tree and, under high gas pressure and flow rates, apparently worked as a lever prying the two trees apart, straining the Torus connector. Investigation of the causes, including a metallic defect test, is still underway.

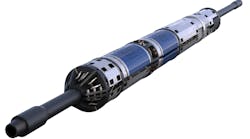

CalDive tests hot top drive

There was a showdown of sorts on the Troika Field last October when the CDI semisubmersible Uncle John, running a pipeline connector tool, was able to lower its drillstring, in single stands, faster than a nearby rig was able to set pipe running triples. The key was a specially designed top drive with a collett system that allowed the operator to rotate the top drive 90! to the side. Thus, the drive unit could attach to a section of drill pipe in the horizontal mode, as well as vertical.This six-finger collett system can open up and allow the operator to go over the top of the drillstring in the horizontal or vertical mode. The collett can then be closed halfway to the lift position so the pipe can spin in the collett, allowing the operator to break-out pipe below. It also can be set in the lock position allowing the operator to drill or torque with up to 23,000 ft-lbs.

In an operating scenario, the top drive will pick up the stand of pipe in the horizontal position from the self-elevating gun loader, rotate it to the vertical position, lock on it, drill the stand, then release the string. The operator then can lift the top drive a couple of feet, and turn the top drive 90!. At this point, the gun loader then brings up another joint, and the collett fingers close on the joint. The top drive picks it up in the horizontal position and turns it downwards into the vertical position. When elevated, the joint of pipe is only a foot or two above the string, which is resting in the slips. The operator lowers the joint, spins it in, puts the tongs on, torques it up, pulls the slips, and begins drilling.

Ken Duell, Senior Vice President of Deepwater Development for CalDive International, said drillers were initially skeptical of this one-of-a-kind system, developed by CDI, Dreco, and Fugro, but have now seen it in action and are impressed.

A better way to inspect threads

In many cases, washouts and twist-offs are prevented by regular inspection of the BHA. According to BP, the new ACFM thread inspection system, developed by Technical Software Consultants overcomes many of the practical difficulties encountered by the magnetic particle inspection of dye penetrant inspection systems. One of the reasons these traditional systems are only about 60% reliable in finding cracks in the BHA is that they depend on the visual acuity of the inspector. Also, these inspections required that the threads be carefully cleaned before hand.The ACFM technique is used widely in other areas of the offshore industry for such things as platform inspections, both topsides and underwater. The method provides various advantages including reduced requirements for thread cleaning, more reliable detection of cracks and crack depth, and a simple pass/fail report that does not require a highly skilled operator.

The system also stores a permanent record of the inspection for future review. Light, hand-held probes can be swept 360! to inspect all critical areas of the thread. The system determines if the inspection was properly carried out then process the data to report pass or fail. Comparative trials show the system prototype performed better than the MPI in a similar amount of time. BP reports the system should be ready to market later this year.

Ursa successful after flow troubles

After shallow water flow problems drove Shell's contract driller off the original Ursa site, the company reports success at nearby Mississippi Canyon 809. Shell has successfully drilled three wells past the shallow water flow zones and hopes to batch set a total of 12 wells at this new location before installing the TLP to complete these wells.Earlier this year, Shell Offshore reported nine of 20 pre-drill wells on its Ursa project in Mississippi Canyon Block 810 washed out due to shallow water flows. The problems occurred during the setting of the 20-in. casing string. During the batch setting of these strings, at approximately 2,000 ft, shallow water flows up the annulus caused the failure of the wells.

Ursa partners, Shell, Conoco, Exxon, and BP decided to move the Transocean Offshore semisubmersible rig Rather offsite to drill in MC Block 809. Shell said they did not use any new tactics to overcome the shallow water flow problem, but simply chose a more stable area to drill.

British-Borneo solution clarified

British Borneo Vice President of Production Mike Adams clairified a description of a shallow water flow solution which appeared in a February article. British-Borneo used several supply boats to provide 9.5-12.5 ppg water based mud to the Atwood Hunter operating in Garden Banks 258. The operator used 16,000 bbls of this mud in a riserless drilling operation to get through a section between 1,981 ft and 3,796 ft below the mud line.Adams said this solution was cost effective, using standard spud mud at $30/bbl, and allowed the driller to set a 20-in. casing string "relatively deep". The well reached a TD of 21,000 ft with an 8.5-in hole. Adams pointed out that the mud used was determined to pose no environmental risk.

Copyright 1998 Oil & Gas Journal. All Rights Reserved.