Offshore staff

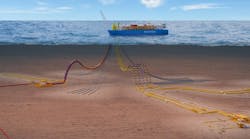

GLASGOW, Scotland –Swagelining Ltd., Saudi Aramco, and The Welding Institute have started a joint industry project to investigate the use of polymer lining in carbon steel pipelines. The JIP will examine the extent of corrosion incurred in a polymer lined pipeline when subjected to a sour hydrocarbon fluid environment.

The JIP is divided into two parts. Part A, sponsored by Swagelining and Saudi Aramco, will use applied testing on lined pipe sections to determine the corrosion rate during simulated service conditions for 180 days.

This section of the JIP will also look at liner collapse during multiple pressure cycles, and how this can be prevented by implementing an internally vented system which will be represented by Swagelining’s LinerVent.

Part B is funded by TWI and will look to gain an understanding of the transport processes through the partially confined polymeric layer.

Dr. Steve Brogden, technical engineering manager at Swagelining Ltd., added: “We hope to attract input from further parties which can add value to this JIP, particularly in the latter stages as we look to perform tests under strenuous conditions. As the offshore oil and gas industry continues to move into more hazardous and extreme environments, it is critical that we demonstrate how polymer lining systems can continue to be used.”

02/19/2015