Offshore staff

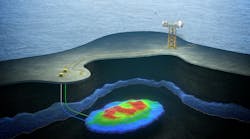

HØVIK, Norway – DNV GL has published a recommended practice (RP) on how to establish, implement, and maintain an integrity management system (IMS). The aim is to help operators carry out maintenance activities at the most cost-effective intervals, increase confidence in the condition of the subsea equipment, and ensure a unified and reliable reference for both authorities and the industry.

The RP (DNV GL-RP-0002: “Management of Subsea Production Systems”) is the result of a two-year joint industry project (JIP) involvingDONG Energy, FMC Technologies, GDF Suez, Norske Shell, Statoil, Talisman, the Petroleum Safety Authority, and Norwegian Oil and Gas. The JIP explored typical subsea equipment failures and how the integrity of subsea equipment could be controlled.

Failures in subsea production systems can, for example, arise from inadequate design, manufacturing, and installation. In operation, material degradation as well as structural threats, natural hazards, and operational threats, might cause failure of the system. Information management and documentation is a particular challenge, and organizational interfaces can also impede clear communication and exchange of operational data across operators’ organizations.

12/15/2014