Offshore staff

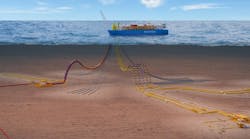

HOUSTON –T.D. Williamson (TDW), a pipeline specialist that has carried out thousands of pipeline pressure isolation operations between its STOPPLE plugging system and SmartPlug pipeline isolation technology, was recently retained to isolate pressure in a Gulf of Mexico riser so that a wye could be safely installed and so that divers, who would be working 228 m (748 ft) subsea near the open end of the line, would be safe.

As one of its core isolation technologies, TDW typically uses its SmartPlug tool to isolate pressure in specific sections of pipelines and risers so that repairs or interventions can be carried out safely. Operated by remote control, the SmartPlug tool is certified to “Safety Class High” in accordance with OS-F101 for Submarine Pipeline Systems. It is uniquely certified and type-approved byDet Norske Veritas (DNV) to execute independent double-block isolation to provide a safe environment for divers while working near a pressurized gas pipeline.

For this job, TDW developed a custom solution that provided the dive specialist with a safe, reliable method of isolating the riser and platform from the section that was to be prepared for the wye installation.

Before the line was isolated, it was imperative to ascertain whether the line was piggable, and that the specially sized (or engineered) SmartPlug tool would be able to negotiate the tight bends in the riser to reach the set location. TDW conducted a piggability and pipeline stress simulation study by bi-directionally running a modified gauge pig, similar to the SmartPlug tool, to simulate the exact path of the isolation tool during the forthcoming operation. The study confirmed that the SmartPlug tool would successfully traverse the piping and reach its target destination.

Working from the platform, the TDW crew launched the SmartPlug tool into the riser. As the tool traveled through the riser, the TDW team onboard the support vessel used its remote-controlled SmartTrack tracking and monitoring system – which uses two-way, through-wall electromagnetic communication between a transponder and a receiver – to track the tool’s progress, control its speed, and monitor conditions in real time. When it reached its subsea set location of 228 m (748 ft), the tool was set into position, where it remained for 3.5 days, isolating the riser against a pressure of 63 bar (914 psi).

Secure in the knowledge that the line was safely isolated, divers cut the line in preparation for the tie-in. Throughout the operation, divers worked near the open-ended line with only the SmartPlug tool preventing the gas pressure from escaping. The wye spool was installed, and the SmartPlug tool was retrieved through a valve fitted with a temporary receiver. The procedure was completed on schedule and without incident.

Keeping the divers safe while installing the piggable wye on time was a major achievement, signaling that the next step of the plan to tie in the line to the new deepwater oil and gas project could proceed.

The task was carried out using technologies offering continuous pressure and subsea condition reports, giving the dive specialist the confidence to proceed with the installation. As a result, it was installed efficiently, well within the designated time frame.

08/04/2014