‘Connected vessel’ approach can help modernize FPSO design, operations

Editor's note: This story first appeared in the July-August 2022 issue of Offshore magazine. Click here to view the full issue.

By Greg Trostel * Rockwell Automation; and Roger Burnison * Sensia Global

Digital technologies are changing what’s possible on floating production storage and offloading (FPSO) vessels. They’re leveraging capabilities like data-based insights, AI learning and remote connectivity to make operations more predictable, productive and low-risk. As a result, they’re creating a new type of FPSO vessel – a connected vessel.

But in order to realize the true value of a connected vessel, you first need to rethink how these vessels are designed and built.

A connected vessel has key requirements – like seamless connectivity across systems, access to performance and diagnostic data, and robust cybersecurity. The vessel also must be flexible across its operating life to support the addition of new and better technologies as they become available.

The problem is, the traditional process used to design and build FPSO vessels doesn’t fully address these needs – which is why it needs to change.

The traditional approach used to design and build FPSO vessels is often fails to take into account the needs of a ‘connected’ FPSO vessel. Why? Because it prioritizes near-term implementation over long-term performance.

For instance, the traditional approach addresses needs like a sound mechanical engineering design and cost-effective implementation, which are obviously critical to any FPSO project. But it doesn’t address long-term production needs and optimization opportunities that can help you realize significant savings and additional revenue across the entire life of the vessel.

The contracting methodology used to design and build today’s FPSO vessels can also constrain your connected vessel. For example, EPCs too often base decisions on limited technical specifications and factors like lowest cost rather than what’s best for a vessel’s long-term performance. EPCs also have a short-term contractual obligation, meaning they can’t help you address the various changes and challenges that happen over the lifetime of a vessel. Even in instances where the builder is also the vessel operator for a time, they often prioritize a lower capex cost over factors like improved operations.

Another challenge if you’re a vessel owner/operator is that your vessel design often locks you into specific vendor technologies. This limits the technologies that you can use to help optimize insights and operations over your vessel’s lifetime.

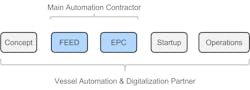

A more holistic approach to designing and building FPSO vessels can help you avoid these problems, so you can get the most value from your connected vessel now and in the years ahead. But adopting a new approach requires that you set new expectations for your main automation contractor (MAC). In addition to their role of supplier and integrator, they need to take on a bigger role as a vessel automation and digitalization partner (VADP) to help modernize the design and construction of FPSOs.

So, what exactly should a vessel automation and digitalization partner do? For starters, they should be responsible for all aspects of your connected vessel’s automation, control, safety and digital processes – not only at the design and build stage but throughout the life of the vessel. Their goal should be to create an open, standardized, secure and digitally enabled architecture, and to help you ensure that architecture is optimized from the commissioning through to the decommissioning stages of your vessel.

A VADP should still fill the role of a MAC and seek cost savings in the implementation phase. But it should also prioritize maximizing ROI across the life of the vessel. This is a critical point of differentiation when you consider that a connected vessel costs several billions of dollars to build. However, the cost of operating the vessel over its life is three to four times that amount.

It’s important to keep in mind that, while your MAC does need to take on a bigger role, they do not need to replace an EPC – it augments the EPC. Imagine placing the full responsibility for OEM module integration onto your VADP. There would be a single party responsible for all interfacing, integration and commissioning – all work that the owner, and certainly the EPC, would be glad to hand-off to someone else.

Already today, some of the world’s largest oil and gas companies are embracing aspects of a VADP approach to reduce integration challenges.

One global company standardized on a single control technology for its topsides and hull packages while also enlisting the control technology supplier to serve as the OEM MAC. Standardizing on one technology helped the company reduce training needs, simplify maintenance and spare-parts management, and create a common IT and security approach. The OEM MAC approach also aligned with the company’s COVID and environmental objectives.

Another global company tasked an OEM MAC to handle everything from the design to the startup of a fully integrated automation system for its FPSO vessel. The integrated system included the vessel’s process control, emergency shutdown, and fire and gas systems, which totaled more than 10,000 hardwired I/O and 30,000 networked I/O. As part of the project, the OEM MAC also managed all aspects of OEM coordination and the integration of OEM systems and packages.

With a more holistic approach to deploying vessels and a partner to help see that approach through, you can position your connected vessel for long-term success.

For example, the right VADP can standardize your control and information architecture so the various systems on your vessel can communicate with each other and seamlessly share data. A standardized architecture can also reduce the number of systems that your staff needs to learn and the spare parts you need to stock on your vessel. And it can reduce the potential for safety risks resulting from interface issues between systems.

This partnership can also give you the flexibility you need with an open architecture. Instead of being locked into certain vendors and their technologies, your architecture is vendor agnostic, so you can use new innovations with ease as they become available.

Additionally, with the right network and instrumentation foundation in place, your partner can help deploy the technologies and digital capabilities you need to optimize performance and reduce risks on your connected vessel.

For example, tools for performance prediction, optimization and maintenance can help you optimize operations and get ahead of downtime issues. And remote connectivity can allow you and your partners to monitor vessel operations and critical systems from afar. This not only gives on-vessel staff fast access to specialized expertise, but it can also help reduce the number of staff required on your vessel and keep costly trips to and from the vessel to a minimum.

Of course, digital technologies will evolve during the life of your vessel. New technologies will emerge, and some existing technologies will become obsolete. To make sure your vessel can evolve with the technology landscape, the right VADP can help you create an open, vendor-agnostic architecture to give you the flexibility you need.

It can be hard to break old habits. But the promise of the connected vessel – like improved productivity, lower operating costs, and reduced safety and downtime risks – demands a new approach to designing and building FPSO vessels.

By adopting a more holistic approach and asking more of your MAC, you can make sure the right foundation is in place for your connected vessel at its onset and proactively address its changing needs for its entire operating life.

The authors

Greg Trostel is Global EPC Business Development Manager, Rockwell Automation.

Roger Burnison is Engineering & Consultancy Services Manager, Sensia Global.