Trendsetter Engineering has completed live well operations with its new 15,000-psi subsea hydraulic intervention system (STIM). Since November 2016, the STIM system has completed seven subsea projects in the Gulf of Mexico in water depths ranging from 762 m to 2,195 m (2,500 ft to 7,200 ft).

The recent live well operation campaign, which was conducted from February-March 2017, consisted of acid stimulation on three wells with water depths as deep as 2,195 m, pressures up to 12,500 psi, and sustained pump rates of 10 b/min.

The campaign was the first to be conducted with a hydraulic well intervention system certified by a BSEE-approved independent third party as fully compliant with the new well control regulations.

Mike Cargol, vice president of Rentals & Services for Trendsetter Engineering, said: “The successful operation of our 15,000-psi hydraulic intervention system on a live well signals the official entry of Trendsetter into the subsea well servicing market. Working with our Offshore Services Alliance partners C‐Innovation and Halliburton, we are excited about what the future holds for both our company and this innovative team.”

OneSubsea to deliver multi-phase boosting system to Otter field

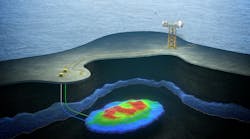

TAQA has awarded OneSubsea an EPCIC contract for a subsea multi-phase boosting system for the Otter oil field in the UK northern North Sea. OneSubsea and its alliance partner Subsea 7 will supply and install the equipment and associated topsides and subsea controls, and other life-of-field services for the 30-km (18.6-mi) subsea tieback to the TAQA-operated North Cormorant platform. This will be the longest subsea multi-phase boosting tieback in the UK North Sea.

Mike Garding, president, OneSubsea, Schlumberger, said the system “will improve TAQA’s ultimate recovery from an existing asset, through a capital-efficient long tieback.”

GE, Aker secure Coral South contracts

GE Oil & Gas has signed a long-term agreement to collaborate with Eni East Africa (EEA) on development projects in Area 4 offshore Mozambique. EEA, a venture owned 71.43% by Eni and 28.57% by CNPC, has a 70% operating stake in the Area 4 concession in the Rovuma basin.

The agreement comprises a multi-year contract to supply subsea production systems, ancillary equipment and services, and covers the recently launched Coral South FLNG project.

Eni awarded the TJS consortium of TechnipFMC, JGC Corp., and Samsung Heavy Industries the engineering, procurement, construction, installation, commissioning and start-up contract for the FLNG facility, its associated risers and subsea flowlines system, and installation of the umbilicals and subsea equipment. Under the first phase, an FLNG vessel will be installed in 2,000 m (6,562 ft) of water with a capacity of around 3.4 MMt/yr of LNG, supplied by six subsea wells and expected to produce up to 5 tcf of gas. Start-up is anticipated in mid-2022.

For Coral South, GE Oil & Gas will supply seven christmas trees, three two-slot manifolds with integrated distribution units, MB rigid jumpers, seven subsea wellheads with spare components, a topsides control system to be installed on the FLNG facility, equipment including IWOCS and landing strings, tools, and spares, and technical assistance for installation, commissioning, and start-up.

Neil Saunders, president and CEO of Subsea Systems & Drilling, GE Oil & Gas, said: “Coral South FLNG is the first major subsea development in East Africa. As the only subsea production systems supplier in-country and in East Africa, it provides tremendous opportunities to grow our operations in the region and it further underlines our commitment to drive productivity and cost-efficiency improvements for global projects by building long-term relationships with industry players in place of more outdated transactional approaches.”

The agreement also applies to future Area 4 upstream projects, and includes a separate five-year aftermarket services contract for life of field of the subsea infrastructure, with extension options. Aker Solutions will supply three steel tube umbilicals, more than 19 km (11.8 mi) long in total, that will connect the FLNG facility to the field’s subsea production system. All will be manufactured at the company’ complex in Moss, Norway, and will be delivered at the end of 2019.

Subsea processing standardization JIP Phase 2 under way

The DNV GL-led joint industry project on standardizing subsea processing has moved into Phase 2. The JIP aims to reduce cost in a lifetime perspective. Initially focusing on subsea pumping, the partners in Phase 1 have now concluded the functional description of subsea pumping, while Phase 2 will deliver standardized guidelines.

The JIP includes system suppliers Aker Solutions, GE Oil & Gas, OneSubsea and TechnipFMC and operators Shell, Statoil, and Woodside. Phase 2 is expected to lead to a guideline and eventually a recommended practice for subsea pumping systems.

Phase 2 activities are related to standards, functional requirements and specifications, system design, pump modules and pressure-containing equipment, control system and instrumentation, power system, materials and welding, and qualification work processes and test requirements.

Kristin Nergaard Berg, JIP project manager, DNV GL - Oil & Gas, says: “Subsea standardization offers tremendous benefits. It allows flexibility for tailor-made facilities at a system level through standard functional descriptions and specifications, while also increasing predictability in the value chain. This will not only lower transaction costs and accelerate implementation for all parties, but also allow freedom to innovate and employ new technology.”