Steam flood, optimized well placement could unlock stranded, North Sea heavy oil

Steve Brown

The Steam Oil Production Company Ltd.

Steam flooding is one of the most effective ways of boosting recovery of heavy oils. Steam injection has been applied very successfully onshore in California, Indonesia, and Oman and offshore in Bohai Bay and in Congo.

The Steam Oil Production Company in London is now seeking to apply steam flooding, to the Pilot, Elke, and Narwhal fields in the UK North Sea, three undeveloped heavy-oil discoveries with large volumes of in-place crude. Steam flooding involves injecting steam continuously into dedicated injection wells: as the steam condenses in the reservoir both the rock and oil are heated up, and the now mobile oil is swept toward the producers by a bank of fresh water. The combination of high temperatures and the fact that the reservoir is being swept by a gas rather than a liquid reduces the residual oil saturation from typically 25% for a cold water flood to just 5% in the steam zone. This and the reduced viscosity has been proven to boost recovery to 50-80% of oil in place.

Although early steam floods deployed close arrays of vertical injectors and producers, later experience has shown that horizontal wells can be more effective, and this is the proposed technique for the Pilot steam flood project. Developing Pilot with a conventional patterns of vertical well penetrations around 100 m (328 ft) apart would require literally hundreds of wells, but long horizontal wells penetrating the reservoir can bring well numbers down by an order of magnitude and achieve a better sweep. Also, if the formation has a high permeability, injection rates into the horizontal wells can be high enough to ensure that heat losses in the wellbore are not a major problem.

The Steam Oil Production Company expects to recover around 60% of Pilot’s in-place oil via a steam flood of the reservoir. But the key to the project’s economic viability is the volume of steam that has to be injected to recover each barrel of crude. The plan is to test different well spacings, injection rates and well positions relative to the oil-water contact in order to optimize the balance between the recovery factor and the steam/oil ratio. Co-injection of steam and methane (or propane) is another option that could increase recovery further and improve the steam/oil ratio, cutting fuel requirements.

There are concerns over the efficiency of steam flooding reservoirs where the oil zone is underlain by a significant water zone, and experience shows that recovery is lower in these cases. However, following investigations the company has developed an innovative approach to this problem which should lead to high recovery factors. Proving that offshore steam works, and testing technologies that enable steam flooding at reservoir depths greater than 3,000 ft (914 m), could make a material difference to maximizing the UKCS’ remaining economic oil recovery, with potentially 2 Bbbl to be recovered via enhanced steam flood from other UK heavy-oil projects.

Pioneer producers

When The Steam Oil Production Company talks to the industry about its plans for its UK offshore fields, however, the general reaction is skeptical. That is not how the industry develops heavy oil in the North Sea: the standard-bearers were the teams that in the early 1990s put together development plans for Alba, Captain, Harding and Gryphon in the central North Sea, the last wave of heavy-oil developments on the UK continental shelf.

Those were stunningly successful projects, none more so than Harding, which is reputed to be achieving a 74% recovery factor from the Harding Central reservoir. Those fields were undoubtedly developed in the best way possible based on the available technologies at the time. This author led the BP team that prepared the Harding development plan in the 1990s which in the end delivered even more than our most optimistic forecasts.

Based on these returns, many in the industry today believe there is a standard formula for developing heavy oil in the North Sea. It is pretty simple: maximize well productivity via long, horizontal production wells, put them as high in the reservoir section as possible, and sweep as much water around the system as you can.

The plans for the currentMariner, Kraken and Bentley developments in the UK northern North Sea, operated respectively by Statoil, EnQuest, and Xcite Energy, do not just pay homage to the fundamental nature of the reservoir depletion programs for these early projects: they copy them. Admittedly, the well density has been tightened, the water handling capacity increased and the well designs take advantage of new technologies such as multi-lateral junctions; but fundamentally, what is being done to these reservoirs is just the same as was done to Alba, Captain, Harding, and Gryphon.

But the heavy oilfields of the 1990s were (Captain excepted) very different from the heavy oilfields that are being developed today. For one thing the oil was not particularly heavy, at 18-21° API, and at reservoir temperature, was not especially viscous, at around 10 centipoise (cP).

The critical parameter in working out how effective a water flood process will be is the mobility ratio; that is, the mobility of water divided by the mobility of oil. If that ratio is too high the sweep efficiency will suffer and the recovery will be less. Captain’s oil has a reservoir viscosity of about 90 cP, which means the mobility ratio is about 10 times the Harding mobility ratio, so the expected recovery factor for its water flood is about 35%, about half of the Harding recovery factor.

The next generation of heavy oil fields feature oil with reservoir viscosities as high as 1,500 cP. Viscosities that high make a huge difference to the proportion of oil in the fluids coming out of the ground. It is not only the recovery factor that suffers, the water handling capacity required also soars. The ratios change as viscosity increases. For Bentley, based on Xcite’s reservoir modeling, the proportion of oil in the produced fluids is just 4.4%, so the company will have to produce nearly 6 Bbbl of fluids in order to get over 250 MMbbl of oil out of the ground. That is an extraordinary volume of fluids and it takes a huge amount of money and energy to do that.

What is the alternative? The oil is the oil, you cannot change that, but you can change its viscosity. Oil viscosity changes dramatically with temperature, and steam happens to be hot. Indeed at Pilot reservoir pressure, steam is 600°F (315°C) hot, and at that temperature the oil viscosity is in single digits.

Steam flood procedures

No one disputes the potential for steam flooding to deliver a very high recovery factor, if it could only be applied to the high permeability heavy-oil sandstone reservoirs encountered in theNorth Sea.

The recovery factor case for steam is well proven. However, the general belief is that the cost of steam, especially the cost of generating steam offshore, will far outweigh the benefits. That is not the case, although you do have to consider carefully how and when to apply a steam flood. Most people imagine that steam flooding is an enhanced oil recovery (EOR) technique, and EOR techniques tend to come into consideration after all the easy, inexpensive oil has been captured and the field is on its last legs, and the operator is desperately trying to defer decommissioning.

That is how most steam flood projects have started. But it actually makes no sense to push water into a heavy oil field to force some oil out only to have to sweep all that water out of the reservoir with steam as you try to boost the recovery factor. No, the right way to go about it is to steam the reservoir from the start; and to steam it quickly. The key to a successful steam flood is to minimize the heat losses and the way to do that is to inject steam at as high a rate as you can and to sweep the reservoir between injectors and producers as quickly as possible.

The Steam Oil Production Company has devised a production profile for a steam flood of the entire Pilot field, based on the thermal reservoir simulation done so far. The profile is flat and short and the proportion of oil in the fluids pumped out of the reservoir is projected to be even higher than for the Harding field. The field life is just 11 years, not the 35 years required to produce Bentley with a water drive scheme.

That represents a two-thirds saving in operating costs. Combine that with the reductions in facilities capacities and there is more than enough capital saved to pay for the steam boilers. The cost of the gas that has to be burned is not trivial but between a doubling in reserves and the operating cost savings the economic case for steam is well made.

But what about the emissions and the carbon footprint? In a conventional water drive scheme all that water does not move around the reservoir all by itself - it takes energy to do that and energy that is expended for more than 30-odd years.

Based on Xcite’s 2013 environmental statement the carbon footprint of producing Bentley oil was over 60 kg carbon-dioxide (CO2)/bbl. A gas-fired steam flood of Pilot with a steam/oil ratio of about 2 bbl of steam for each barrel of oil would probably have a carbon footprint of about 55 kg CO2/bbl. That is already an improvement on the Bentley plan: it is a heavier footprint than the 35 kg CO2/bbl Statoil anticipates for Mariner, but not by much. It is a gap that technology could bridge.

If the steam/oil ratio for Pilot could be improved, so could the carbon footprint. MEG Energy has suggested this is possible, having seen a dramatic improvement in steam/oil ratio following implementation of a methane co-injection scheme at its SAGD project onshore in Alberta. MEG claims a 70% reduction in steam requirements. If the Pilot scheme could achieve a steam/oil ratio of about one, that is a 50% reduction in requirements, the carbon footprint could be among the best in the UKCS, hopefully as low as 30 kg CO2/bbl. And that makes the environmental case for steam.

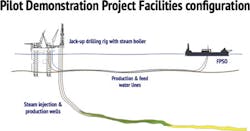

The Steam Oil Production Company plans to demonstrate that steam flooding can be done offshore. The company is working on the design of a demonstration steam flood project to be carried out on a segment of the Pilot field. The plan is to drill seven wells, three injectors and four producers, 100 m (328 ft) apart, inject steam into the reservoir at a rate of around 36,000 b/d of cold water equivalent and produce between 15,000 b/d and 20,000 b/d over a period of three years. This will be done in the middle of the North Sea, in 80 m (262 ft) of water, and no-one has attempted anything of this scale offshore before.

The wells will be drilled from, and tensioned back to, a jackup with a steam boiler installed on its deck (yes, it will fit). An FPSO will also be needed to process and store the oil and to prepare the boiler feedwater. That sounds like a lot of equipment, but the key to the project economics is to make use of otherwise idle equipment and to work with contractors and suppliers who have the vision and energy to help make a technological breakthrough happen.

We believe there are around 2 Bbbl of additional reserves to be recovered in the UK North Sea if all the applicable fields were steam flooded, not counting Premier’s recent Bagpuss discovery. That is a huge prize and if we can get this demonstration project underway it will make a real contribution to maximizing economic recovery in the UKCS.

The author

Steve Brown is a founder and the CEO of The Steam Oil Production Company Ltd. He is a petroleum engineer with over 30 years of experience. Holding a degree in Chemical Engineering from Peterhouse, Cambridge, he started his career as a petrophysicist with BP. He worked on the Forties Bravo field and the development of the Harding and Andrew fields as well as in BP’s corporate planning department. He has also worked for Halliburton and Petrofac as well as founding Challenge Energy, Exile Resources, and Setanta Energy.