Sarah Parker Musarra • Houston

DeepStar announces long-distance tieback study

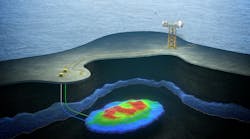

Over the last 50 years, technological advancements have spurred the evolution of subsea production systems. For example, long-distance subsea tiebacks have allowed these systems to move from operating in shallow-water close to the shore or a platform to producing in deepwater locations more than 60 mi (100 km) from supporting infrastructure.

Although not very commonplace in the industry today, DeepStar says that it expects to see the number of long-distance subsea tiebacks to increase as the industry ventures into deeper waters and harsher climates. To this end, the industry body launched a new study in November 2015 to identify new subsea system architecture for fields located more than 50 mi (80 km) from their host facilities. This new system would then serve as a first step in developing a more robust solution for future long-distance subsea fields.

DeepStar selected INTECSEA to perform the desktop configuration study, which is projected to conclude in March.

The study aims to review and clarify the operating requirements of a representative subsea field configuration while identifying and evaluating key advanced technologies for integration. It will also look to summarize the status of additional technologies for integration, both existing and to be developed.

It will also define a path forward for eventual deployment, including plans to address technology gaps as well as engagement plans for strategic partners and standardization entities.

DeepStar considers that technological advances are key to the economies of scale necessary to ensuring that these long-distance fields remain economically viable. Deepwater subsea developments require sizeable capital investments, which are typically repaid a few years after start-up, while the field still has a long operating life.

The study intends to identify economies of scale that could reduce capital investment enough to make long-distance tiebacks economically viable where conventional methods would not be, enabling significant returns on investments.

The strategic value of an investment in this study is clear, DeepStar said. Beyond a reduction in capital, technological advances could also reduce potential risk and increase in operational flexibility and performance.

The advanced technologies considered in this study will consist of three main components: all-electric subsea and downhole systems; fiber optic networked communications for control and data acquisition; and subsea processing. In defining the elements of the new architecture for the subsea system, the study assumes that the technology is 10 years out from field deployment, so both existing and emerging technologies will be considered.

FMC delivers another tree for TEN project

FMC Technologies has delivered the eighth subsea tree for the Tullow Oil-operated TEN field development offshore Ghana four weeks ahead of schedule.

FMC Technologies is assembling and testing all subsea trees for the project at its recently expanded facility in Takoradi. Awarded in 2013, the contract has led to training and development of Ghanaians who represent 76% of the local workforce.

Weighing around 40 tons (36 metric tons), the subsea trees are vital pieces of equipment which control the flow of fluids into and out of the oil and gas wells. A total of 22 subsea trees will be installed as part of the project - one for each well.

Ramboll to assess integrity of Zakum subsea pipelines

Zakum Development Co. (ZADCO) has awarded Ramboll Oil & Gas an inspection contract offshore Abu Dhabi. This involves an integrity study of 15 subsea pipelines serving the Zakum oil field, allowing ZADCO to plan future maintenance and potential equipment replacement needs.

Ramboll’s scope includes a review of available pipeline data, assessment of current and future pipeline integrity for future operations, and calculation and prediction of the corrosion growth rate.

Production from Zakum started in 1983. The goal of this project is to extend the design and service life of selected pipelines by an additional 20 years.

Bibby Offshore secures infrastructure project

Bibby Offshore was granted a multi-million pound contract by BP to replace subsea infrastructure in the UK central North Sea as part of the $1-billion Eastern Trough Area Project (ETAP) Life Extension Project. ETAP comprises six fields operated by BP (Marnock, Mungo, Machar, Monan, Mirren, and Madoes) and a further three by Shell (Heron, Skua, and Egret). The ETAP Life Extension Project (ELXP) will help secure the future of the fields until 2030 and beyond.

The Bibby Offshore ELXP contract involves installing new subsea control system infrastructure to safeguard power and communication links to ETAP’s Machar, Madoes, and Mirren fields, some 150 mi (241 km) east of Aberdeen.

From April 2016, the company will provide dive support and construction support vessels from its international fleet to deliver services including; umbilical installation, trenching, structure installation and commissioning, through to final survey of the completed work scopes.

DNV GL advances codes program

Aquatic Engineering & Constr- uction is assisting DNV GL and other subsea organizations on guidelines for “The Development of Codes for Offshore Equipment for Cable and Pipe Laying - Phase 1.” These will be incorporated into new or existing DNV GL offshore standards or recommended practices.

The work will see engineering and technical experts from contractors and equipment manufacturers collaborating to establish joint industry guidelines for cable and pipelay equipment. Subject to satisfactory completion of the first two phases, a third phase undertaken by DNV GL will result in the publication of an offshore standard or recommend practice for cable/pipelaying equipment.

Other Phase 1 participants are Allseas Engineering; Amclyde Norson Engineering; IHC Engineering Business; IHC SAS; MAATS Tech; NLI Offshore & Marine Products; Parkburn Precision Handling Systems; Reel SAS (IMECA); Saipem Group; Subsea 7; and Technip UK.