Versatile diverter tool reduces surge in deepwater wells

Jason Lacombe, Mark Murray

Weatherford

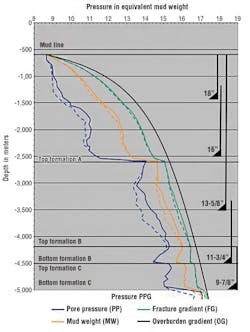

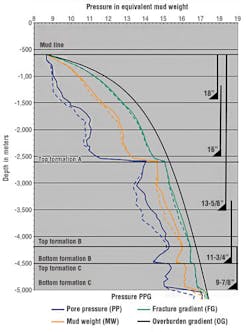

Surge pressure, the phenomenon caused by fluid displacement when moving pipe into the wellbore, is a fact of life in every well. The degree of the surge is traditionally not problematic - assuming an adequate margin exists between pore pressure (PP) and fracture gradient (FG).

However, with the industry’s steady and determined move into complex deepwater plays, surges have become a force to be reckoned with. They are most often in depleted fields where the window between pore pressure and fracture gradient narrows significantly, increasing sensitivity to pressure on the formation. Failure to control that pressure can cause the formation to fracture, result in fluid loss, and ultimately compromise cement quality. In some cases, the uncontrolled pressure can lead to a well-control event. Reducing surge pressure increases the rate at which crews can run casing and liner into the wellbore, an important consideration for operators in today’s economically challenged environment.

Over the past decade,deepwater arenas such as the Gulf of Mexico have become increasingly depleted, causing the PP/FG window to tighten considerably. In response to that trend, surge reduction has become an established practice in the deepwater market, with a host of tools and methods that divert fluids from the casing and drill pipe into the inner annulus. Diverting the fluid dramatically improves tripping speed while maintaining well integrity by reducing the risk of fracturing the formation. Surge reduction is especially critical in tight casing strings and open holes, where any slight additional overbalance, or surge, could cause the well to take fluid, causing loss of mud and a possible kick.

A surge reduction system includes the use of autofill float equipment, such as shoes or collars, placed at the bottom of the casing to reduce equivalent circulating density (ECD) downhole. The shoe typically has an open bore to allow fluid to pass while the float collar contains the check valves that are used to hold the cement in place after the cement job. After the autofill equipment is converted, fluid can no longer pass from the well into the inner diameter (ID) of the casing or liner.

The system also includes a drill pipe diverter positioned above the running tool of the casing hanger or the liner hanger. The diverter tool directs the mud, or fluid, from the ID of the drill pipe into the annulus, just above the running tool.

Conventional surge-reduction solutions include single-action tools that are run in the open position to displace fluid and thereby increase liner- and casing-running speeds. The tool must then be activated, or closed, to enable circulation to recover from lost returns or wash through restrictions.

Most of the conventional, single-action tools are converted with pressure, which creates an additional pressure surge on the formation. This surge occasionally converts the float equipment at the same time. Furthermore, once the tool is closed, usually using a ball-activated sleeve, it cannot be re-opened to divert fluids. This means that continued casing running must be dramatically slowed, adding time to the operation and increasing the risk of stuck pipe or a dangerous pressure surge and potential blowout.

When closed, many single-action systems also leave a restricted ID, which can cause compatibility issues with different types of setting tools and darts and further exacerbate the surge.

Open/close capability

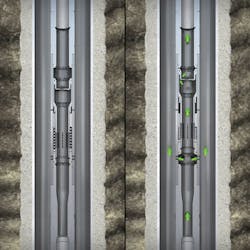

To overcome these limitations, Weatherford has developed a diverter that provides greater versatility by enabling circulation on demand, with the ability to continue to divert flow from the casing and drill pipe to the annulus when the circulation requirement is finished. The SurgeMaster II multiple-opening diverter tool is designed to open and close with each movement of the pipe, as many times as necessary, to reduce surge pressure and increase casing and liner running speeds. The tool has seen more than 50 successful deployments in the Gulf of Mexico, as well as other deepwater basins globally.

Unlike single-action diverter systems, the multiple-opening diverter tool is run into the hole in the closed position. Large bypass ports open automatically as drill pipe is run into the vertical or horizontal wellbore, diverting mud into the annulus above any restrictions. When pipe movement stops, the ports close.

The ports are opened when flow-induced backpressure acting against a curved flapper forces the inner sleeve to compress the body spring while sliding up, reducing the surge. A small opening in the flapper allows a metered filling of the running string, protecting the drill pipe from collapse pressures, and minimizing the risk of overfilling.

Because the normal, or neutral, position of the ports is closed, the running string can be circulated as often as necessary, at any point in the wellbore, without permanently deactivating the tool. This feature provides the additional benefit of decreased response time without losing the capability of the diverter.

The tool’s unlimited open/close capability enhances well integrity. If a well-control event does occur, the tool closes immediately upon pumping kill fluid. This closes the bypass hole in the diverter and enables normal well-control mitigation procedures without any additional shear pressure, which creates a surge event in a well that may already be experiencing a kick.

The cyclic function of the tool is deactivated by increasing the running string’s internal pressure to a preset amount, which saves time and improves safety by eliminating the need for an intervention. If, for any reason, the diverter does not close, a tube can be dropped downhole to physically close the valve.

Rated for temperatures up to 300°F (149°C), the full-bore tool eliminates the problem of ID restrictions, further enhancing safety and reducing time and complexity. Various activation devices, such as darts for cementing the casing in place and balls to set liner hangers, can be easily deployed downhole with no compatibility considerations, reducing the risk of subsequent pressure surges that can lead to failure in the wellbore.

Multiple casing strings

In 2014, the multiple-opening diverter tool was deployed in the Gulf of Mexico to run and cement four primary casing strings of varying sizes in a deepwater well with a close-tolerance casing design and a strong probability of high surge, lost circulation, and wellbore instability. The operator’s objective was to eliminate losses during casing-running and cementing operations, including circulating the well. Due to the narrow PP and FG window, using the appropriate mud weight was crucial to maintaining an equivalent static density (ESD) and ECD within an acceptable range.

The project began with extensive pre-job planning, including use of surge/swab prediction software, which simulates the ECD with and without the surge reduction tool. Developed to enhance analysis and design of tripping operations, especially for deepwater wells, the software models complex wellbore designs, multiple pipe sizes and annular sections with tight PP/FG windows. It takes into account drilling equipment, fluid properties, wellbore geometry and other parameters, providing valuable information for decision makers.

Based on the simulations, the operator decided to deploy the diverter tool with autofill float collars and large-bore subsurface-release (SSR) casing wiper plugs to run and cement 18-in., 16-in., 14-in. and 11¾-in. casing strings to the target depth. Additionally, the team used a plug-locator system and a locator ring on the top wiper plug for all the casing sizes, except the 18-in. string.

The team tripped into the well with casing on the landing string. The diverter tool enabled circulation to be established without converting the autofill float equipment, which reduced both mud gel strengths and annular friction and pressures at the casing-setting depths. The mud weights and ECD remained within acceptable limits and below the FG. Mud weights ranged from 10.6 lb/gal for the 18-in. casing to 14 lb/gal for the 11¾-in. string. The ECD remained within a margin of 0.05 to 0.10 lb/gal.

The diverter tool, along with the wiper plugs, plug-locator collars and centralizers with placement modeling enabled more than 25,000 ft (7,620 m) of casing to be run to the desired setting depths at speeds averaging between 25 and 35 ft/hour (7.6 and 10.7 m/hour), with no mud losses incurred. The team also was able to circulate, condition, and execute primary cementing operations, eliminating the need for subsequent remediation.

The plug and plug-locator systems performed as planned with the applicable casing sizes. Cement was displaced with pressure indications observed as the top plugs passed through the plug-locator collar and the top wiper plugs bumped on the respective float collars.

Running liner systems

In the Italian sector of the Adriatic Sea, the multiple-opening diverter tool efficiently ran two liner systems in a depleted gas production well with low pore and fracture pressure. The operator’s objectives were to run 11¾-in. and 95⁄8-in. liners to total depth (TD) while managing the high surge and circulating pressures anticipated during the liner-running. Additional challenges included running through tight tolerances, minimizing mud losses, and avoiding mud spills on the rig floor.

After conducting hydraulic simulations using the surge prediction software, Weatherford deployed a liner hanger, a liner-top packer for isolation, an autofill shoe and a large-bore autofill collar along with SSR plugs and the multiple-opening diverter tool.

The first liner system was run to a TD of 10,000 ft (3,048 m) and the second liner system was run to a TD of 11,200 ft (3,414 m), both at a rate of approximately 40 ft/min (12 m/min) while avoiding mud losses. The rate calculated to about 2½ minutes per stand.

The autofill collar was converted with a flow rate of 5 bbl/min and a resulting pressure drop of about 600 psi (41.4 bar). To set the liner hanger and hydraulically release the running tool, a service technician deployed a 21⁄8-in. brass ball, which landed on the mechanical ball seat and sheared the disk. The cement job was accomplished by releasing the SSR plugs from the top-drive cementing head. After the packer was set and successfully tested to 1,500 psi (103.4 bar), the disk in the multiple-opening diverter tool was ruptured and mud was reverse circulated through the diverter tool.

The approach delivered significant benefits, enabling the operator to run the liner systems faster than with conventional methods, while completely avoiding mud losses and saving rig time. The low-flow-rate conversion of the autofill collar effectively eliminated the need to deploy a ball to convert the collar, thus minimizing the circulating pressure on the wellbore and avoiding losses. There were no mud spills or recordable incidents.