Feasibility study assesses two dry tree options for the Gulf of Mexico

Roy Long

National Energy Technology Laboratory, US Department of Energy

Operators in the Gulf of Mexico (GoM) are increasingly looking to ultra-deepwater (>5,000-ft-1,524 m water depth) fields and more challenging reservoirs to deliver the hydrocarbons that the energy market demands and to satisfy their production growth objectives.

These deep subsalt reservoirs frequently have complicated issues, including additional required drilling, more complex completions, artificial lift requirements, and workover/intervention complexity.

These issues point to the use of dry trees as the most economical solution. In many cases, the depth of the reservoir requires a large drilling rig and drilling variable payload, resulting in very large topsides which challenge the limits of current spar technology.

Project overview

DNV GL was granted an award by the Research Partnership to Secure Energy for America (RPSEA), partially funded by the US Department of Energy's National Energy Technology Laboratory, to manage a project to develop dry tree semi concepts for the ultra-deepwater fields in the GoM. DNV GL's role in this project was twofold:

- To manage, on behalf of RPSEA, further development of two semisubmersible concepts suitable for drilling and production in the GoM ultra-deepwater, using dry trees.

- To act as an independent third-party verification agent for assessing the maturity of all safety and environmentally critical aspects of the concepts so that they are "project-ready" in the Gulf of Mexico.

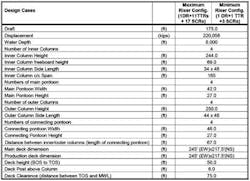

Under the aegis of this project, two previously developed dry tree semisubmersible concepts were further matured for operation at 8,000-ft (2,438 m) water depth in the GoM:

- Paired Column (PC) semisubmersible developed by Houston Offshore Engineering (HOE)

- Deepwater Dry Tree Semisubmersible (DWDTS) developed by Kvaerner Field Development (KFD).

Both concepts had previously gone through some development (i.e., previous RPSEA funded projects, DeepStar funded projects, etc.). The current RPSEA project focused on critical design elements identified in the earlier work. In evaluating the designs, DNV GL endeavored to ensure that both concepts were developed in accordance with the same design basis. Of course, each design has its own unique challenges, which have been the focus of DNV GL's evaluation.

In previous projects, the following elements were identified as the most critical issues for each concept:

- Vortex-induced motion (VIM) and quayside integration for the HOE PC semi concept

- Riser tensioner qualification for the Kvaerner DWDTS concept.

Both concepts underwent VIM model tests and extensive engineering work. DNV GL conducted AiP evaluations for both concepts and TQ for each riser tensioning system. DNV GL concluded that the above critical elements have been adequately addressed for the purposes of conceptual design. Therefore both concepts are considered feasible, and can be regarded as "project ready," provided all comments and suggested actions in this report are properly addressed in the next project phase (e.g. FEED).

This project involved a large number of subject matter specialists from the industry and from DNV GL in key steps during design basis assessment, progress review, model tests, and final Conceptual Hazard Identification (HAZID) workshops. Throughout the project, the objectives have been to ensure that the concepts (1) are in line with industry practice and (2) meet the requirements for safe operation in the GoM. The discussion that follows is an update on this project, completed in December 2014 and originally discussed in Offshore in June 2012.

Dry trees for the Gulf

GoM dry tree solutions have been dominated by spars and tension leg platforms (TLPs). For water depths beyond about 6,000 ft (1,828 m), the TLP typically becomes cost prohibitive. For large payload systems, especially those requiring large drilling payload, the spar size, transportation options, and offshore installation become a challenge. The semisubmersible vessel offers several advantages over the spar option, including larger deck space and the possibility of quayside topsides installation and integration. It is expected that the dry tree semi will be cost competitive with the spar in most cases and will overcome the size limitations of the spar option.

The industry has shown significant interest in developing a dry tree semi solution over the last few years to increase contracting options. However, there remains an uncertainty about the total system maturity, constructability, performance, and cost efficiency. So far no dry tree semi has been selected as a host platform for large payload systems in ultra-deepwater.

Objective

Building on recent development of dry tree systems, this project is aimed at delivering project-ready and cost competitive dry tree semi solutions for the GoM in a minimum of 8,000-ft (2,438-m) water depth with drilling and production capabilities for moderate to large payloads.

The objective has been to consider two promising hull forms with the associated riser tensioning systems that make use of conventional technologies to the greatest extent possible. Key technical challenges and/or new technologies, which require qualification before being field ready, are to be addressed with associated technology qualification plans developed.

The study also identified deployment opportunities associated with each solution with respect to field applications and considerations for overall safety, equipment limitations, fabrication, transportation, installation, and geographical locations.

Displaying 1/3 Page 1,2, 3Next>

View Article as Single page