Study assesses challenges of extending spars and semis into ultra-deepwater

Richard B. D’Souza

Rahul Subramanian

Granherne, a KBR Company

Rajiv Aggarwal

Independent consultant

The offshore industry is currently capable of developing deepwater oil and gas fields, and installing subsea infrastructure and floating platforms in the US Gulf of Mexico (GoM) down to 2,500 m (8,200 ft) water depths. Beyond 1,600 m (5,250 ft), developments have been limited to semisubmersibles, truss spars, and tanker-based floating production storage and offloading (FPSO) platforms with subsea developments.

Spar and semisubmersible platforms have been used extensively in the GoM as hosts for large deepwater developments. Spars have progressed from 600 m to 2,600 m (1,970 ft to 8,530 ft) water depths since 1995, and semisubmersibles from 450 m to 2,500 m (1,480 ft to 8,200 ft) since 1985. Industry has now set its sights on producing in water depths down to 4,500 m (14,760 ft).

Hulls have grown to accommodate increasingly larger topsides, riser, and mooring payloads. Extending these platforms to 4,500 m represents an almost 80% increase in water depths. The main challenges relate to the technical feasibility and installation of risers and mooring systems and their impact on the size and global performance of the hulls.

Recently, Granherne conducted a study on the impact of extending semisub and truss spar designs to 4,500 m water depths. The study involved using DNV GL’s Sesam DeepC suite of software to conduct fully coupled nonlinear time domain global performance analyses for both semisub and truss spar designs, for 2,500 m and 4,500 m water depths. In brief, the results indicate that it is feasible to extend conventional truss spar and semisub platforms out to 4,500 m water depths.

Study parameters

Today, there are ten platforms installed in the GoM in water depths greater than 1,500 m (4,920 ft), all with subsea wells.

For subsea developments, steel catenary risers (SCRs) are typically utilized for production, water injection, gas lift, and export. Their designs vary in diameter and thickness and are sensitive to hull motions. The feasibility of SCRs with semisub hulls has been a challenge in some cases, and operational and design measures have been adopted to meet strength and fatigue requirements near touch down zone (TDZ). Some operational and local design measures included distribution of fatigue damage by shifting vessel position; use of clump weights or heavy weight coating above TDZ; and pipe-in-pipe designs. Deep draft semisub hull designs were developed to reduce vertical motions at SCR porches. The deeper hull semisub is susceptible to vortex induced motion (VIM) in eddy currents, impacting fatigue performance of risers and mooring lines.

This study contrasted spar and semisub platform global performance in 2,500 m and 4,500 m water depths. The production scenarios considered in this study were for large topsides payloads (greater than 22,000 metric tons, or 25,250 tons). Truss spar designs for Tahiti and Holstein fields are the most relevant to define the current qualified size, technologies, and construction limits. In addition, Aasta Hansteen, the first spar for the harsh North Sea region, provides upper limits for hull constructability. Among the semisub designs, the Atlantis (designed pre-Katrina), and Jack/St. Malo (JSM) facilities, designed for post-Katrina metocean criteria for large payloads, are the suitable candidates.

Field development scenarios

Since this study focused on GoM developments, a review of likely water depths in the frontier region was conducted to locate the platforms. The review showed that very deepwater depths of 4,000 m and deeper would fall in the western and transition metocean zones. The Sigsbee Deep region, located in the southwestern quadrant, is the deepest region of the GoM. The Sigsbee Abyssal Plain is a deep and flat portion of the Gulf bottom. The maximum depths range from 3,750 m (12,300 ft) to 4,400 m (14,430 ft). This region is south of the locations of the Atlantis and JSM semisubs. Post-Katrina transition zone metocean criteria were used for this study.

A major production hub platform designed to support a large number of subsea wells tied back by production and water injection SCRs is a likely development scenario in frontier regions of GoM, similar to several existing developments in water depths greater than 1,500 m.

The following development components apply for both semisub and spar-based development scenarios:

- Drilling and well intervention of subsea wells at distance from the platform undertaken by a MODU

- Topsides functions including process equipment for large production throughput, water injection, subsea boosting, subsea flow assurance, utilities, and oil and gas export via pipelines over long distance

- Chain-polyester-chain mooring system in a spread pattern

- SCRs for production, water injection and export lines.

Design basis

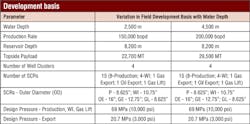

For the purposes of this study, oil production rates of 150,000 b/d and 200,000 b/d were assumed for 2,500 m and 4,500 m water depth, respectively. These rates are similar to existing large platforms in the Gulf. Four or more clusters of production and injection wells were assumed with flowline loops for pigging operations from the platform.

For hull sizing and global performance assessment, the deck size, payload, and projected area estimates based on the design basis varied with water depth and hull type. The deck plan area and projected wind areas for 2,500 m water depth increased by 15% for the 4,500 m water depth designs. The semisub based design could be a box deck with two-level truss modules or an integrated two-level truss deck, whereas, the truss spar design would require a three-level truss deck.

Global performance

The hull sizes, weights, displacements, and preliminary estimates of global performance and stability were derived from Granherne’s benchmarked sizing tools. The past work for platforms in 3,000-m water depth showed that time domain coupled global performance analysis was required. This includes interaction of mass and stiffness of moorings and risers to capture platform response, and its impact on the designs of moorings and risers. Therefore, fully coupled nonlinear time domain global performance analyses were conducted using DNV GL’s Sesam DeepC suite of software for both semisub and truss spar designs for 2,500 m and 4,500 m water depths.

The DeepC analysis model was generated using the vessel hydrodynamic model from HydroD which considered the floating hull with topsides as a rigid unit. The mooring lines and SCRs were modeled with multiple elements in each line and riser, to reasonably represent their mass distribution and stiffness properties. The analysis was performed for random seastates generated for design and survival levels. The focus of the analysis is to estimate platform global motions, maximum and minimum tensions in mooring lines and risers, and bending moment variations in SCR at seabed.

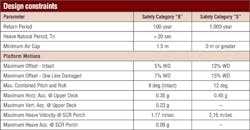

Semisubmersible designs

With the semisub platform designs, the two-level deck structure is built in modules, which are placed on the box deck that is fabricated with the hull. The bottom of steel (BOS) elevation of box deck is kept above the crest elevation of the 100-year return period (RP) seastate. A negative airgap is allowed for the 1,000-year RP seastate. The process, quarters and utility modules are placed on the box deck. The mooring winches are located on top of the deck box above the columns.

The operating displacement for the Semi-4500 is about 160,000 metric tons (mt). Major contributors to the displacement are hull lightweight (40%), topsides, risers and umbilicals, and water ballast (about 20% each). The Semi-2500, has a higher percentage of the total displacement as water ballast and a lower percentage of risers and umbilicals. The heave and pitch natural periods for Semi-4500 are 23.4 sec and 38 sec, respectively. Dimensions of columns and pontoons and draft can be varied to obtain different combinations with improved global performance.

A conventional chain-polyester-chain mooring design anchored by suction anchors is the basis for 4,500 m water depth. The number and size of mooring lines are related to the limits of platform offset in the design basis. Lower platform offset requires larger diameter polyester mooring lines with high pretension. Frequency domain analysis using MIMOSA was conducted to verify platform offsets and mooring line tensions for compliance with the design basis. The design consisting of four groups of five lines with 268-mm polyester rope and 162-mm steel chain was deemed to be satisfactory.

Mooring line tensions are the dynamic maximum at top and dynamic minimum at bottom. The line tensions in polyester segments on windward side are estimated as 0.40 MBL and 0.53 MBL in design and survival level analysis respectively.

The results from the study showed that the increase in maximum tension in SCRs from Semi-2500 to Semi-4500 designs range from 1.8 to 2.3, which would require use of buoyancy modules over long length of riser such as used with the steel lazy wave riser. The maximum utilization ratios in SCRs at hang-off for Semi-4500 are estimated to be 1.5 to 2 times of the designs for Semi-2500. The results show that semisub designs are feasible with proven polyester mooring and riser system technologies.

Comparison with existing designs

The field development scheme is the same as Atlantis and JSM. Both of these facilities are located in the transition metocean zone. Jack/St. Malo is the largest semisub in the ultra-deepwater GoM, and has been designed to the new post-Katrina metocean criteria. The Semi-4500 displacement estimate is about 10% greater than the JSM semisub, from larger hull lightweight and greater riser payload. The displacement estimates for Semi-2500 are about 36% higher than the Atlantis semisub designed to pre-Katrina metocean loading.

The overall hull dimensions for Semi-4500 are similar to the JSM semisub. Thus, the JSM execution plan with fabrication of hull in Far East yards, and transportation of hull by heavy transport vessel (HTV) to GoM, and integration at quayside would apply to the Semi-4500 design. Installation of longer mooring lines and anchors, SCRs, and umbilicals would take longer than with JSM but since they are pre-installed, impact on overall schedule would be minimal.

Spar designs

With the truss spar designs, the mooring fairleads are shown at hard tank and SCRs are supported at the keel, i.e., at the soft tank level, with pull tubes in the well bay. The three-level deck structure is an open deck design using vertical trusses. The elevation of BOS of lower deck (cellar deck) is kept above the wave crest elevation for survival seastate. The airgap estimated from mean sea level (MSL) to BOS of lower deck is 23 m, and spar hull top is 17 m above MSL with 6 m deck stools.

Both truss spar configurations have two heave plates. The hull lightship weights differ by about 10%. The hull diameter, draft, and freeboard dimensions variation is moderate. The controlling design constraints in truss spar sizing for GoM are: maximum pitch angle and minimum air gap. These are obtained by placing solid ballast in the soft tank to lower the center of gravity (CG) of the truss spar design, which reduces pitch and heave, and increases airgap estimates.

The conventional chain-polyester-chain mooring design with chain at top and bottom and anchored by suction piles is the basis for Spar-4,500. A 3x5 grouped configuration with 259-mm (10-in.) polyester rope and 147-mm (5.78-in.) steel chain at top and bottom is required to meet offset criteria.

The in-place operating displacement for Spar-4500 is 147,640 metric tons (162,745 tons) with free flooded water in soft tank. Contributors to the displacement are topsides, risers and umbilicals, free flooded water in soft tank, and hull lightweight, that vary from 19% to 24% of total displacement. The heave and pitch natural periods are 27 sec and 45.5 sec respectively.

Due to very low vertical heave velocity and acceleration at the SCR connection with hull, the design level minimum tensions in SCRs are larger and about 28% less than the estimates for dynamically sensitive SCR designs for Semi-4500. The minimum tension at bottom of SCRs would be lower for the survival seastate. Thus, the conventional SCR design is feasible for a truss spar and would not require buoyancy modules to reduce tension.

Comparison with existing designs

The field development scheme employed for the study was similar to the Tahiti and Lucius developments in the transition metocean zone. The Holstein spar is the longest and heaviest truss spar designed to support dry trees with RAM tensioners, but it was designed to pre-Katrina metocean criteria. The largest truss spar under construction is for the Aasta Hansteen development in the North Sea, with subsea tiebacks and includes condensate storage in hull.

The Spar-2500 and Spar-4500 hull designs require two heave plates as do most of the recent wet tree truss spars in GoM. The overall hull lengths are 182 m and 184 m (597 ft and 603 ft), respectively, for the two designs, which are longer than Tahiti (169 m) and shorter than Holstein (227 m) and Aasta Hansteen (193 m). The hull lightship weight and solid ballast for Spar-2500 is similar to Holstein. The hull lightship weight for Spar-4500 at about 35,000 mt is between Holstein (32,000 mt) and Aasta Hansteen (41,000 mt).

The Aasta Hansteen spar has undergone significant qualification work, since it is the first truss spar in the North Sea in harsh metocean conditions. The displacement of Spar-4500 with flooded soft tank is 147,640 metric tons, and is similar to the Aasta Hansteen.

Conclusion

The offshore industry is acquiring leases in frontier regions in up to 4,500 m water depths. Presently, drill rigs are capable of drilling wells in these depths, but proven capability of floating production platforms is only 2,500 m. This study investigated the feasibility of extending wet tree semisubmersible and truss spar production platforms to 4,500 m water depths, an 80% increase over current capability. The work resulted in the following conclusions, detailed below.

Truss spar and semisub hull displacements to support topsides, riser, and mooring payloads increase by 20% to 30% in extending water depths from 2,500 m to 4,500 m, but hull configurations and weights are within industry capability to design, fabricate, transport, and integrate/commission topsides.

Fully coupled non-linear time domain analysis with all risers and mooring lines modeled conducted for conventional four column semi-sub and truss spar in 2,500 m and 4,500 m showed that current analysis tools can predict global performance in 4,500 m. The impact on global motions in the deeper water depth is nominal. However, there should be a rigorous industry effort to calibrate analytical tools via model tests be conducted to increase confidence in global performance predictions.

Conventional chain-polyester-chain spread moorings with suction piles can be extended to enable spar and semisub station keeping in 4,500 m depths. A nominal increase in number of lines and line size is required for offset control, and these are within industry capability to manufacture. Installation of mooring lines in 4,500 m is feasible with current heavy-lift crane vessels. Additional qualification work is required for suction pile lowering, suction pumps, and ROVs.

The key challenges in extending floating platforms to 4,500 m are the risers. SCRs were used as the basis and it was concluded that these cannot be extended to 4,500 m because of excessive tension for about 20% suspended length below hang-off point. Bending at TDZ is not an issue, nor is fatigue expected to be an issue. Solutions include adding buoyancy modules such as in a lazy wave or alternative configurations such as tower risers or buoyant tethered risers, which are proven to 2,500 m water depths.

Based on this preliminary investigation, there do not appear to be any “show-stoppers” in extending conventional truss spar and semi-sub platforms to 4,500 m water depths. More rigorous sizing and analytical work is recommended before making definitive conclusions. Qualification work is required regarding certain mooring and riser system components, and detailed mooring and riser installation assessment is recommended.