Patience pays off for Macedon partners

Russell McCulley

Senior Technical Editor

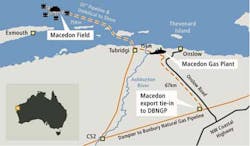

In August, BHP Billiton turned on the taps at the Macedon gas development, a four-well subsea tieback to an onshore plant near Onslow, Western Australia. The field, in the Exmouth basin WA-42-L lease area, is in water depths of 170-180 m (558-591 ft) and is estimated to hold between 400 and 750 bcf in recoverable reserves - a small field, relative to the LNG megaprojects nearby, but one that is expected to feed as much as 20% of the state's daily gas demand. And in many respects, the $1.5-billion project was a milestone for BHP Billiton.

It was also a long time coming. BHP Billiton, operator of the WA-42-L block, which includes the Pyrenees FPSO project, made the gas discovery in 1992; sanction would wait nearly two decades. "This was our third attempt to commercialize Macedon gas," says Garry Walker, who was BHP Billiton's Macedon project director before recently relocating to Houston to serve as senior manager of shale projects. The problem was the gas itself: lean, with 94% methane content and no ethane, characteristics that made it ineligible under the regulations at the time to travel through the Dampier to Bunbury Natural Gas Pipeline, WA's main transmission route. "The heating value didn't meet the pipeline requirements," Walker says. "To get our gas into that pipeline, we needed the regulations governing what could be carried through that pipeline to be changed, and they were changed in 2009. That really was the green light for Macedon."

The regulations were changed in the aftermath of the 2008 explosion at Apache Corp.'s Varanus Island gas plant, which cut off about 30% of WA's domestic gas supply for several months. "The government rightly recognized that it was a good idea to have some depth in supply, and there we were with Macedon. Macedon gas was the only new gas that could come on in this period between 2010" and the startup of WA production from big LNG projects such as Gorgon, Wheatstone, and Pluto for domestic use, Walker says.

With one hurdle out of the way, there still remained the task of getting the gas from the field to the Dampier to Bunbury line. BHP Billiton had a plant in the area - the idle Griffin Gas Plant - but there was little else in the way of infrastructure at the proposed landfall, south of Onslow. Macedon is about 100 km (62 mi) offshore; BHP Billiton considered bringing the gas ashore at the nearest landfall, the town of Exmouth. But the area lies in a protected zone around the World Heritage-listed Ningaloo Marine Park.

"We looked at an offshore platform," Walker says. "But the field is quite spread out, so we'd still need subsea tieback to the platform, and the cost was prohibitive. It's a relatively small accumulation, quite a long way away. The benefit of building a platform would be that we could downsize the pipeline, but the platform cost outweighed the benefits." The company also considered developing Macedon as a tieback to the Pyrenees field, which is in a different geological structure, but opted instead to bring the gas directly to shore.

"Once we decided on the subsea tieback to the beach, we looked at either controlling it from the beach, through an extended reach umbilical, or to have a local buoy," Walker explains. "And based on the environmental and safety risks associated with having surface facilities out on the ocean in a cyclone-impacted area, we decided to go with the extended reach umbilical - 66 km [41 mi] single length of umbilical, tied into a 13-km [8-mi] nearshore umbilical."

BHP Billiton and its WA-42-L partner, Apache Corp., submitted a plan to WA authorities that included a pipeline route traversing the shortest distance to shore. But there was a hitch, in the unassuming guise of an endemic species of cowry found only in a stretch of the Indian Ocean next to Peak Island, where the proposed route would run. "So we had the choice of managing our impact on that species of shellfish, or moving the pipe. We moved the pipe, and took a more northerly route, which got us into deepwater quicker, and then we doglegged across." The change meant an additional 3 km (1.9 mi) of pipe and umbilicals would be needed. Oceaneering was contracted to provide umbilicals, related hardware, and a subsea pig launching system (see sidebar). Cameron supplied the Macedon trees and subsea control system; the flowlines were manufactured by Wellstream, with concrete coating provided by Bredero Shaw in Batam, Indonesia.

The high-density coating was necessary to overcome another challenge. "It's a 90-km [56-mi] pipeline, and you've got to get quite a long way offshore before you get into deepwater - about 42 km [26 mi] before we got to 50 m [164 ft] water depths," Walker says. "And in that nearshore area, where it's shallow, the pipeline is subject to a lot of forces, especially cyclones. We were concerned about its on-bottom stability during cyclones. To fix that, when we did the original design we specified secondary stabilization - basically, rock dumping - all the way out to 42 km. That was going to cost a lot of money."

The partners put out a tender for the rock-dumping scope. But the rerouting of the pipeline following the discovery of the cowry colony sent engineers back to the drawing board. "We started doing the redesign, and we did a lot of analysis. We looked at pushing the concrete weight coating envelope as far as we could, to 120 mm of high-density concrete. We used that in the critical nearshore areas, and were able to eliminate the rock dump."

BHP Billiton opted for corrosion resistant alloy (CRA) pipe near the wells to mitigate the risk of water condensation. "The Macedon gas has only got 0.4% carbon dioxide, so it's not really corrosive," Walker explains. "But with water condensation in the very near-wells locations, we were concerned about corrosion on the top of the pipeline."

The zone in question stretches 400 m (1,312 ft) and includes the Macedon manifold and inline skid, where one well ties in. Condensation control, had CRA not been used, would have meant regular pigging. "And we don't want to regularly pig, because it's a subsea intervention operation," he says. "So everything in the manifold to the well is carbon resistant alloy. It's an expensive solution, but a more certain solution."

The Macedon export line requires periodic pigging nonetheless - first for commissioning, and infrequent "smart" pigging thereafter to measure the pipe thickness for corrosion, as required by law and to meet BHPB's own standards. To accomplish this, the company built its first subsea pig launcher. "On the manifold, we've got a connector, so we can bring the subsea pig launcher down, connect up, discharge the pigs, and then recover the launcher to the surface. It's an intervention process—we used it during the commissioning of the pipeline, and the dewatering. It worked really well," Walker says.

In the end, Macedon's long gestation may have been a blessing: it gave BHP Billiton time to think through the design, Walker says. "I think that anybody embarking on a project in this kind of environment really needs to go out and do as much as they can in terms of geophysical and geotechnical surveys," he says. "The more you know about the seabed, the better—and it does change over time. We did what we thought was adequate geotechnical/geophysical. It would have been really nice to have more, especially with the challenge of the (pipeline) stabilization. If we'd had more data we could have been more aggressive in our design, and done more analysis. That's really my takeaway from the project. The more information you have about the geophysical, geotechnical, and metocean data, the better."

Distance, remoteness, and 'creature features' test Oceaneering's design teams

The Macedon project's subsea-to-shore field layout presented more than a few challenges, particularly for Oceaneering International, which BHP Billiton contracted to supply umbilicals and related hardware.

"In the end, it was 15 steel tube and electro/optic umbilicals, about 120 km (75 mi) altogether, and 17 major hardware pieces," including a subsea pig launcher, says Oceaneering Umbilical Systems (OUS) Technical Sales Manager Alun Rees. "It was a huge project, probably the largest one (OUS) had ever done at Oceaneering."

One aspect of the job was the need to extend the umbilicals more than 15 km (9 mi) inland to the processing plant. "That was unusual for us," Rees says. "We build umbilicals for subsea. But we had to bring it ashore, trench it along the beach, get through some sand dunes, through some wetlands, under a river, more wetlands, and finally the plant."

This being Western Australia, there were "some flora and fauna issues to get through," he notes. For the onshore portion, the umbilical electric power cables had to be coated in nylon to protect against electrical cable-eating termites; offshore, the tubes passed through a lengthy stretch prone to Teredo worms, or shipworms, that burrow into ship hulls, and are also fond of electrical cables. To discourage them, the shallow water and subsea power cables include a layer of copper tape.

To connect the shallow water and subsea sections of the main umbilical, Oceaneering developed a connector that could be retrieved from the seafloor, used to connect both sections, and then re-deployed to the seabed. Another connection had to be made in the main onshore section, where the umbilical was split into two separate cables to meet installation weight limitations. The onshore umbilicals had to be divided into multiple sections no heavier than 50 metric tons (55 tons), including the installation reels and pieces of hardware. "The challenge was, if you've got all these short lengths, how are you going to join them together in the outback with no infrastructure?" Rees says.

Oceaneering Subsea Products' engineering team, including VP of business development Michael Cunningham, came up with custom-built connection systems for the umbilicals that allowed them to be assembled onsite, both onshore and offshore. "Having to make the thing up offshore was a pretty significant challenge," Cunningham says. Oceaneering had performed a similar operation offshore, in the Gulf of Mexico. "But that was a thermoplastic hose-style umbilical, so torsion in the umbilical was quite easy to deal with, relative to the steel tube one. That's where the idea for (an inline joint installation tool) came into play, so we could actually manipulate the ends of the umbilical to align the two halves of the splice to be able to mate them."

Low-loss fiber was included to keep the umbilicals' circumference, and overall weight, within bounds. "Normally, they would have used electric cables for communications, but it's too far - the cables would be too big," Rees says. "So they communicate from shore to the well site digitally, through an optic cable, then when they get to the well site they converted to analog and distributed communications via electrical cables."

During the Macedon planning process, BHP Billiton asked Oceaneering to come up with a design for a subsea pig launcher. "They wanted the unit to be able to do commissioning work on the pipeline at the completion of installation, and then to do operational pigging, including intelligent pigging operations," says Cunningham. "They asked us to come up with a design that they felt was the least risky for a single flowline system."

Oceaneering had done similar work on other projects, albeit on a smaller scale. "Even though it was ROV operable, the complexity was significantly greater than what we had done in the past for commissioning systems," he continues. BHP Billiton "wanted different types of pigs to be deliverable through the system, and to the best of my knowledge, this may be the first one that can deliver an intelligent pig from the subsea location, certainly the first we'd ever done."

During pigging operations, the pig launcher attaches to the subsea manifold via an Oceaneering Grayloc clamp-style connector. "It is not a self-contained system in that it has to have intervention from the surface, both from an ROV to operate the barriers between pigs, and also to deliver the kicker fluid required for initial motivation," Cunningham says.

The industry has long sought a pig launching system for single-flow projects such as Macedon, he adds. "But it's got significant challenges. If you're going to bet the farm - basically, bet the wells - on a single pipeline system, then you better be pretty darn comfortable that you can get a pig from the well location back to the beach without getting stuck somewhere."

Overall, Rees says, Macedon was "one of the most challenging umbilical jobs that Oceaneering has ever had. Usually, we're faced with depth and weight. Here, it was not the depth but the length, horizontally, and the environmental challenges. And then these odd creature features. It was very interesting. And it worked well - the relationship has always been good with BHP."